ODM PCB: Customized Original Design Manufacturing for High-Performance Electronics

In modern electronics development, ODM PCB (Original Design Manufacturing PCB) offers companies a complete solution from design to production. Unlike standard PCB manufacturing, ODM PCB services include custom design, prototyping, engineering support, and original manufacturing, enabling businesses to bring high-performance, fully tailored products to market quickly.

What Is ODM PCB?

An ODM PCB is a printed circuit board developed and manufactured according to a customer’s specific design requirements. The ODM process often covers:

-

Complete schematic and layout design

-

Multilayer PCB fabrication

-

Component sourcing and BOM optimization

-

Assembly and functional testing

This approach allows companies to focus on product innovation while leaving PCB design and manufacturing to experienced ODM partners.

Benefits of Choosing ODM PCB Services

-

Fully Custom Design: Tailor every aspect of the PCB, from stackup and layer count to high-speed signal routing and impedance control.

-

Engineering Support: Professional guidance on design optimization, DFM (Design for Manufacturing), and test planning.

-

Rapid Prototyping and Small Batch Production: Validate and iterate designs quickly before full-scale production.

-

Quality Assurance: Original manufacturing ensures high reliability, precise tolerances, and consistent performance.

Applications of ODM PCB

ODM PCBs are widely used in industries where precision and performance are critical, including:

-

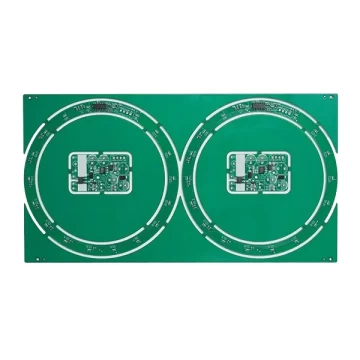

High-frequency and RF modules

-

Automotive electronics and radar systems

-

IoT and wearable devices

-

Industrial control and automation systems

In these applications, ODM PCB services provide a faster, more reliable route from concept to market-ready product.

Key Considerations for ODM PCB Projects

When selecting an ODM PCB partner, companies should consider:

-

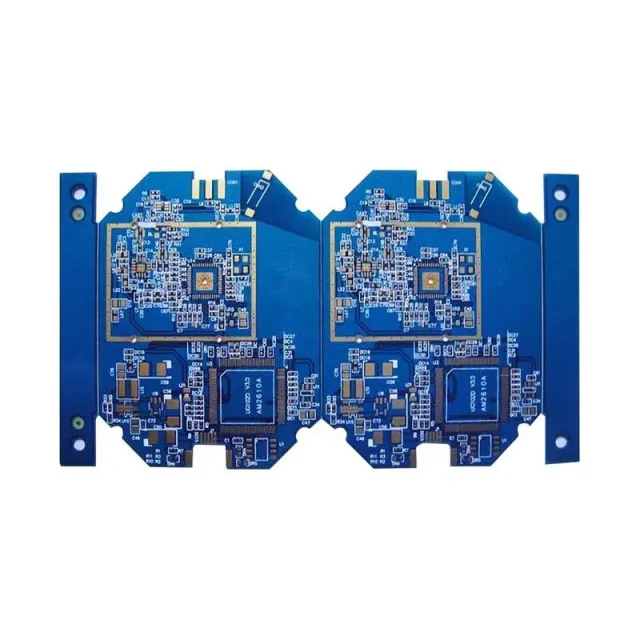

Capability to support complex multilayer or high-speed designs

-

Experience in high-frequency, controlled impedance, or rigid-flex PCBs

-

Engineering and technical support for design optimization

-

Quality control processes including AOI, X-ray inspection, and functional testing

Choosing the right partner ensures the PCB meets both performance and production requirements.

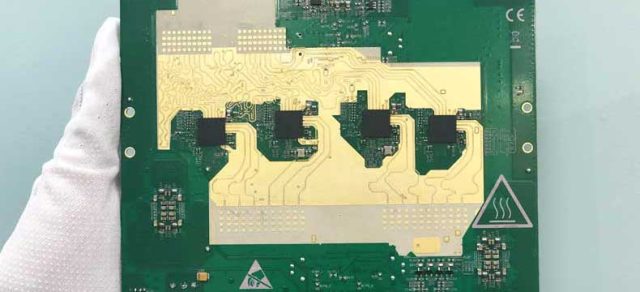

Why KKPCB Is Your ODM PCB Partner

At KKPCB, we offer full ODM PCB services, from initial concept design to final assembly and testing. Our engineers optimize designs for signal integrity, thermal management, and manufacturability, while our manufacturing teams ensure reliable, high-quality PCB production. Whether for prototypes or mass production, KKPCB’s ODM PCB solutions accelerate time-to-market and improve product reliability.

Conclusion

ODM PCB services empower companies to develop highly customized, high-performance PCBs without investing heavily in in-house design and manufacturing capabilities. With the right ODM PCB partner, businesses can achieve faster iterations, higher reliability, and a smoother transition from prototype to full production.