As electronic products become smaller, lighter, and more functionally integrated, traditional rigid PCBs and cable interconnects often fail to meet modern design requirements. Multilayer rigid-flex PCBs combine rigid and flexible circuits into a single structure, enabling compact layouts, improved reliability, and enhanced electrical performance. Working with an experienced multilayer rigid-flex PCB manufacturer is essential to achieve consistent quality and long-term reliability.

What Is a Multilayer Rigid-Flex PCB?

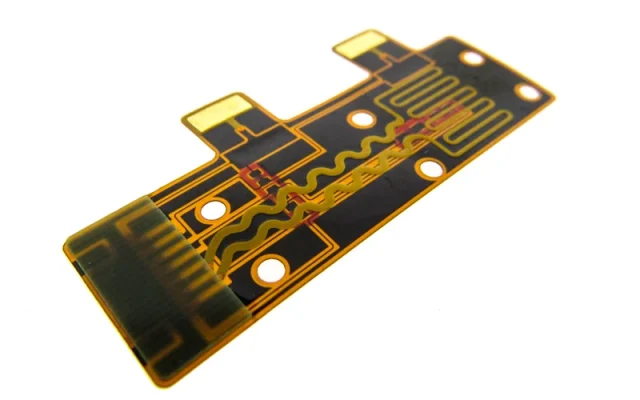

A multilayer rigid-flex PCB integrates multiple rigid PCB layers with one or more flexible circuit layers. This structure eliminates connectors and cables, allowing three-dimensional assembly and improved signal integrity.

Key features include:

-

Multiple rigid layers for component mounting

-

Flexible layers for dynamic or folded connections

-

Seamless electrical integration between rigid and flex sections

These characteristics make rigid-flex PCBs ideal for space-constrained and high-reliability applications.

Advantages of Multilayer Rigid-Flex PCBs

Partnering with a professional multilayer rigid-flex PCB manufacturer offers significant advantages:

-

Reduced interconnect and assembly complexity

-

Improved signal integrity and electrical reliability

-

Enhanced mechanical durability under vibration and movement

-

Compact, lightweight product design

-

Lower system-level assembly cost

Rigid-flex technology is widely adopted in advanced electronic systems.

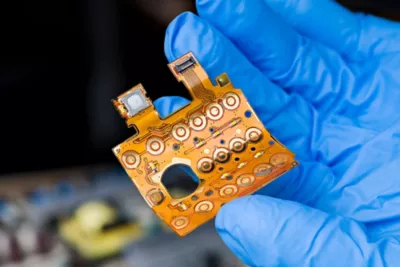

Manufacturing Challenges in Multilayer Rigid-Flex PCBs

Multilayer rigid-flex PCB fabrication is highly complex and requires specialized expertise, including:

-

Precise lamination of rigid and flexible materials

-

Controlled flex bend radius and thickness

-

Accurate layer registration across rigid and flex sections

-

Stress management to prevent delamination or cracking

An experienced multilayer rigid-flex PCB manufacturer ensures process stability and high yield.

Materials Used in Multilayer Rigid-Flex PCB Manufacturing

Professional manufacturers carefully select materials to meet electrical and mechanical requirements, such as:

-

Polyimide (PI) films for flexible layers

-

FR-4 or high-Tg materials for rigid sections

-

Adhesiveless flex materials for improved reliability

-

Copper foils optimized for flex durability

Material compatibility is critical for long-term performance.

Quality Control and Reliability Assurance

A qualified multilayer rigid-flex PCB manufacturer implements strict quality control, including:

-

AOI and X-ray inspection

-

Electrical continuity and isolation testing

-

Flex endurance and bend testing

-

Thermal and mechanical reliability evaluation

These measures ensure consistent quality across all production stages.

Applications of Multilayer Rigid-Flex PCBs

Multilayer rigid-flex PCBs are widely used in:

-

Medical devices and diagnostic equipment

-

Aerospace and defense electronics

-

Automotive and ADAS systems

-

Wearable and portable electronics

-

Industrial control and embedded systems

These applications demand high reliability and compact integration.

How to Choose the Right Multilayer Rigid-Flex PCB Manufacturer

When selecting a multilayer rigid-flex PCB manufacturer, consider:

-

Experience with complex rigid-flex designs

-

Advanced manufacturing and inspection equipment

-

Engineering support and DFM expertise

-

Quality management and certification standards

-

Proven track record in high-reliability industries

Choosing the right partner reduces development risk and ensures long-term success.

Conclusion

A multilayer rigid-flex PCB manufacturer plays a vital role in enabling compact, reliable, and high-performance electronic products. Through advanced materials, precise manufacturing processes, and strict quality control, professional manufacturers deliver rigid-flex PCB solutions that meet the most demanding application requirements.

By partnering with an experienced multilayer rigid-flex PCB manufacturer, companies can accelerate product development while ensuring consistent quality and reliability.