What Is a mmWave Module PCB?

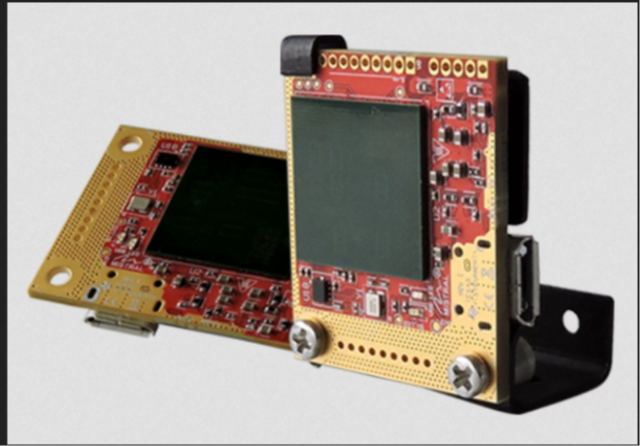

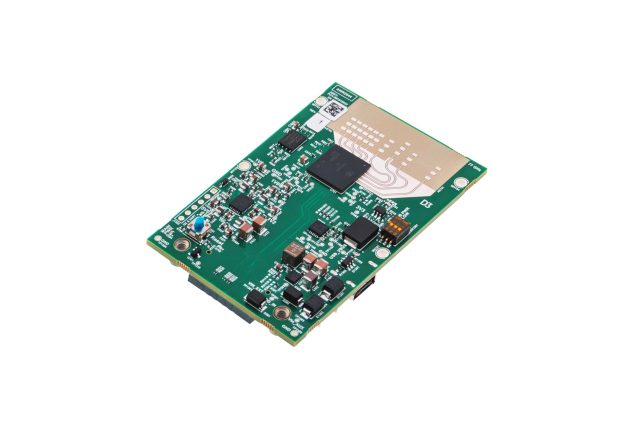

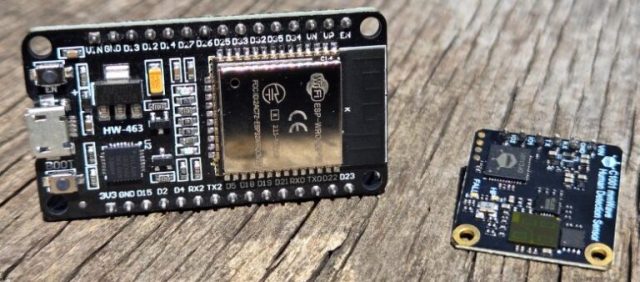

A mmWave Module PCB is a specialized printed circuit board used in millimeter-wave (mmWave) modules, typically operating at frequencies above 24 GHz, such as 26 GHz, 28 GHz, 39 GHz, and 77 GHz. These PCBs integrate RF transceivers, antennas, filters, and high-speed interfaces into compact modules.

Due to the extremely short wavelengths, mmWave Module PCBs demand ultra-low loss materials, precise impedance control, and high manufacturing accuracy.

Key Design Requirements for mmWave Module PCB

A reliable mmWave Module PCB must meet stringent technical requirements:

-

Ultra-low dielectric loss

Minimizes attenuation at mmWave frequencies. -

Highly stable dielectric constant (Dk)

Ensures accurate RF performance. -

Precise impedance control

Critical for transmission lines and antenna feeds. -

Short signal paths and compact layout

Reduces insertion loss and parasitics. -

Excellent surface roughness control

Minimizes conductor loss. -

Strict EMI shielding and isolation

These requirements significantly exceed those of conventional RF PCBs.

Material Selection for mmWave Module PCB

Material choice is critical for mmWave performance:

-

PTFE-based RF laminates

Rogers RT/duroid 5880, RO3003 for ultra-low loss. -

Advanced hydrocarbon ceramic materials

RO4350B, Taconic RF-35 for balanced cost and performance. -

Low-profile copper (VLP / HVLP)

Reduces skin effect losses. -

Hybrid PCB stack-ups

Combine RF layers with control or digital layers.

Proper material selection directly impacts mmWave module performance.

Manufacturing Challenges of mmWave Module PCB

Producing a mmWave Module PCB requires advanced manufacturing capability:

-

Fine line and spacing control

-

Tight impedance tolerance (often ±5% or better)

-

High-precision drilling and via control

-

Accurate layer alignment

-

Advanced inspection and RF testing

Small process variations can significantly affect mmWave performance.

Advantages of Professional mmWave Module PCB Manufacturing

Working with an experienced mmWave Module PCB supplier offers:

-

Optimized RF stack-up design

-

Stable ultra-high-frequency performance

-

Consistent impedance and low loss

-

Reliable quality from prototype to volume production

-

Faster development cycles for mmWave products

These advantages are essential for mmWave applications.

Applications of mmWave Module PCB

mmWave Module PCBs are widely used in:

-

5G mmWave communication modules

-

Automotive radar (77 GHz / 79 GHz)

-

ADAS and autonomous driving systems

-

Satellite and aerospace RF modules

-

High-frequency test and measurement equipment

-

Phased array antenna modules

They are key components in next-generation wireless systems.

Conclusion

A mmWave Module PCB is a critical enabler for millimeter-wave communication and sensing technologies. By combining ultra-low loss materials, precise impedance control, and advanced manufacturing processes, mmWave Module PCBs deliver reliable performance at extremely high frequencies.

Choosing a qualified mmWave Module PCB manufacturer ensures consistent RF performance, high yield, and long-term reliability in demanding mmWave applications.