Introduction to Commonly Used Low-Loss PCB Materials

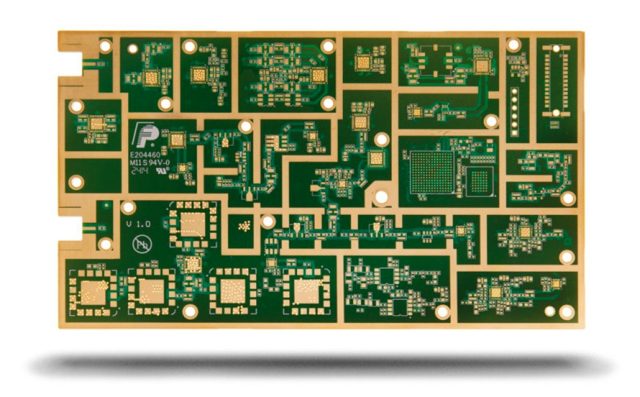

As high-frequency and high-speed electronic designs become increasingly dominant, low-loss PCBs have become the cornerstone of reliable RF, microwave, and high-speed digital systems. These circuit boards are engineered to minimize signal attenuation, power loss, and distortion, ensuring stable performance even at gigahertz-level frequencies.

At KKPCB, we specialize in manufacturing high-frequency, low-loss printed circuit boards using premium materials and advanced fabrication technologies to meet the stringent demands of 5G communication, radar, aerospace, and medical applications.

What is a Low-Loss PCB Material?

Low-loss PCB materials are specialized substrates with low dielectric constant (Dk) and low dissipation factor (Df). These parameters directly influence how efficiently electromagnetic signals propagate through the board. A lower Dk minimizes signal delay, while a lower Df reduces energy loss — both critical for maintaining signal integrity in high-frequency environments.

Typical low-loss materials include:

-

Modified Epoxy and Enhanced Epoxy

-

PTFE (Polytetrafluoroethylene) / Teflon

-

Ceramic-filled or Mica-filled Epoxy Resin

-

Hydrocarbon-Ceramic Composites

These materials provide excellent insulation performance, thermal stability, and low insertion loss, making them ideal for RF transmission lines, satellite systems, and advanced radar equipment.

Key Benefits of Low-Loss PCB Materials

-

Minimal Signal Attenuation: Maintains amplitude and phase accuracy over long trace distances.

-

Superior Signal Integrity: Reduces crosstalk, reflections, and electromagnetic interference (EMI).

-

Improved Antenna Sensitivity: Enhances wireless performance in RF systems.

-

Low Power Consumption: Efficient transmission reduces heat and overall power requirements.

-

High Reliability: Ensures long-term stability under varying temperature and humidity conditions.

-

Compact Design Capability: Enables miniaturization without compromising performance.

Applications of Low-Loss PCBs

Low-loss PCB materials are integral to a wide range of industries where precision and reliability are paramount:

Telecommunications & 5G Systems:

Used in RF modules, antennas, and base stations to reduce signal loss and improve SNR (Signal-to-Noise Ratio).

Automotive Electronics:

Applied in radar systems, ADAS (Advanced Driver Assistance Systems), and EV powertrains for stable high-frequency data transmission.

Medical Devices:

Critical in medical imaging, diagnostic equipment, and patient monitoring systems that demand noise-free signal clarity.

Energy & Power Systems:

Utilized in wind and solar power converters, ensuring efficient energy transfer and minimal thermal loss.

Aerospace and Defense:

Enables reliable data communication and radar tracking in extreme environments.

Comparison of Common Low-Loss PCB Materials

|

Manufacturer |

Medium Loss | Low Loss | Very Low Loss | Ultra-Low Loss |

|---|---|---|---|---|

| Isola | FR408HR, I-Speed® | IS680 AG, Terragreen® | I-Tera® MT40 | Tachyon® 100G, Astra® MT77 |

| AGC (Neltec) | N4000-13, N4000-13EP | N7000-2 HT, N7000-3 | N4000-12SI, N4800-20 | Meteorwave 1000, N9300-13RF, Mercurywave 9350 |

| EMC | EM-370(D), EM-370(Z) | EM-888, EM-A50 | EM-891, EM-528K | EM-892, EM-890K |

| TUC | TU-747LK, TU-862S | TU-872SLK, TU-883A | TU-885, TU-933 | TU-943, TU-787LK |

| ITEQ | IT-150GS, IT-170GRA1 | IT-958G, IT-968 | IT-988, IT-988G | IT-988GA, IT-988GX |

| Panasonic | R-1577, M6 (R-5375) | M6 (R-5775), M7 (R-5785) | M8 (R-5795) | — |

Fabrication Process Insights

The fabrication of low-loss PCBs demands precision manufacturing and controlled environments to maintain the electrical performance of the substrate.

Key process highlights include:

-

High-Precision Etching: Ensures uniform copper patterns with minimal signal reflection.

-

Advanced Plating Technology: Prevents oxidation, enhances adhesion, and stabilizes impedance.

-

Strict Impedance Control: Essential for maintaining consistent transmission line performance.

-

Thermal and Reliability Testing: Confirms board performance under high-frequency and thermal cycling conditions.

Each KKPCB low-loss board undergoes automated optical inspection (AOI), cross-section analysis, and electrical testing to guarantee conformity with IPC-6018 and IPC Class 3 standards.

Conclusion

As the demand for faster, more efficient electronic communication continues to rise, low-loss PCB materials have become a vital enabler of next-generation technology. With advanced engineering expertise and partnerships with top-tier material suppliers such as Rogers, Isola, and Panasonic, KKPCB provides tailored low-loss PCB solutions that deliver high frequency performance, mechanical reliability, and cost efficiency — helping customers stay ahead in the high-speed era.