A professional low loss high frequency PCB supplier plays a critical role in the development of modern RF, microwave, and high-speed electronic systems. As operating frequencies continue to increase in applications such as 5G communication, mmWave modules, radar systems, and high-speed networking equipment, minimizing signal loss and maintaining impedance stability have become essential design requirements.

By providing advanced low-loss materials, precision manufacturing processes, and strict impedance control, a qualified low loss high frequency PCB supplier ensures reliable signal transmission and consistent electrical performance from prototype to mass production.

What Defines a Low Loss High Frequency PCB

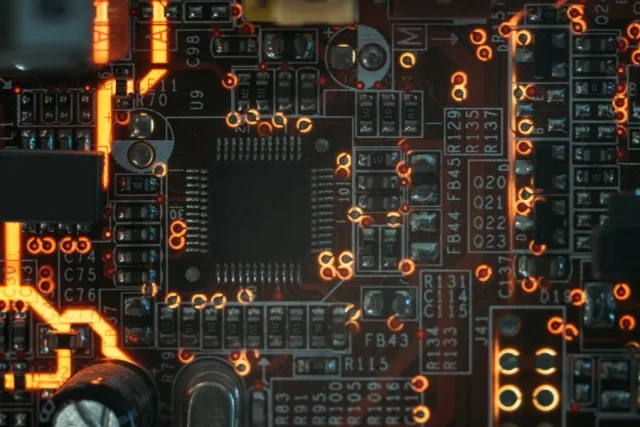

A low loss high frequency PCB is specifically engineered to reduce dielectric loss, conductor loss, and signal distortion at elevated frequencies. Unlike conventional FR-4 PCBs, low loss high frequency PCBs utilize specialized laminates with low dielectric constant (Dk) and ultra-low dissipation factor (Df), enabling stable performance across a wide frequency range.

As a dedicated low loss high frequency PCB supplier, manufacturers focus on controlling material consistency, copper surface roughness, and dielectric thickness to achieve superior signal integrity.

Why Choosing the Right Low Loss High Frequency PCB Supplier Matters

Selecting an experienced low loss high frequency PCB supplier directly impacts system performance, yield rate, and long-term reliability.

Key advantages include:

-

Reduced insertion loss and attenuation at high frequencies

-

Accurate controlled impedance for RF and high-speed signals

-

Improved signal integrity and eye diagram performance

-

Lower crosstalk and electromagnetic interference

-

Stable electrical characteristics across temperature variations

These benefits are especially important in mission-critical RF and microwave applications.

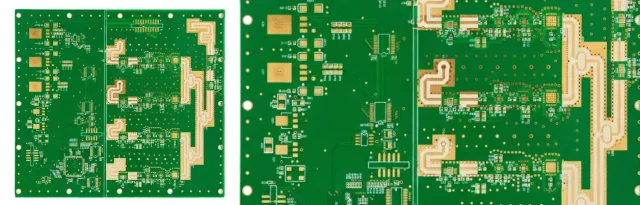

Advanced Materials Used by Low Loss High Frequency PCB Suppliers

Material expertise is a core capability of any qualified low loss high frequency PCB supplier.

Rogers High Frequency Laminates

Materials such as RO4003C, RO4350B, RO4835, and RT/duroid 5880 are widely adopted due to their excellent electrical stability, low dielectric loss, and proven reliability in RF and microwave PCB designs.

Taconic Low Loss Materials

Taconic RF-35, TLY-5, and similar laminates offer consistent Dk and low Df performance, making them ideal for mmWave, antenna, and high-frequency module applications.

Hybrid and Low-Loss FR-4 Solutions

For mixed-signal designs, hybrid stack-ups combining low-loss materials with high-Tg FR-4 provide a balanced solution for cost and performance.

A professional low loss high frequency PCB supplier assists customers in selecting the optimal material based on frequency, thermal requirements, and cost targets.

Manufacturing Capabilities of a Low Loss High Frequency PCB Supplier

Producing reliable low loss high frequency PCBs requires advanced fabrication technology and strict process control.

Core capabilities include:

-

Precision controlled impedance PCB manufacturing

-

Tight dielectric thickness and copper tolerance control

-

Advanced multilayer and hybrid stack-up lamination

-

Fine line etching for RF trace accuracy

-

Laser drilling for microvias and HDI structures

-

Impedance testing and TDR verification

These capabilities ensure every board delivered by a low loss high frequency PCB supplier meets demanding electrical performance specifications.

Design Support and Engineering Collaboration

An experienced low loss high frequency PCB supplier provides engineering support beyond fabrication.

Key design considerations include:

-

Optimized stack-up and reference plane configuration

-

Short, direct RF signal routing

-

Via stub reduction and back-drilling options

-

Proper grounding, shielding, and EMI control

-

Thermal management for stable high-frequency performance

Early DFM and impedance review help reduce design iterations and improve first-pass success.

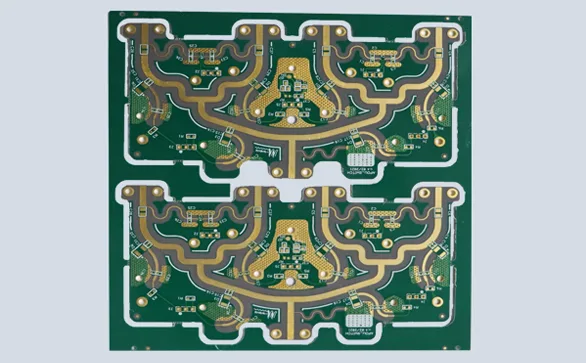

Applications of Low Loss High Frequency PCBs

Low loss high frequency PCBs supplied by specialized manufacturers are widely used in:

-

5G base stations and RF front-end modules

-

mmWave communication and antenna systems

-

Radar and automotive ADAS electronics

-

Satellite and aerospace communication systems

-

High-speed servers and data center networking

-

IoT gateways and wireless sensor devices

In these applications, selecting a reliable low loss high frequency PCB supplier is essential to achieving stable and repeatable performance.

From Prototype to Volume Production

A trusted low loss high frequency PCB supplier supports customers throughout the entire product lifecycle. Prototype validation ensures material performance and impedance accuracy, while consistent process control enables smooth transition to small-batch and mass production with minimal variation.

Conclusion

A qualified low loss high frequency PCB supplier is a key partner in developing high-performance RF, microwave, and high-speed electronic systems. By combining advanced low-loss materials, precise impedance control, and proven manufacturing expertise, suppliers deliver PCBs that meet the most demanding electrical and reliability requirements.

As high-frequency applications continue to expand across communication, automotive, aerospace, and industrial markets, working with an experienced low loss high frequency PCB supplier becomes a decisive factor for product success.