A Complete Engineering & Manufacturing Guide

Introduction

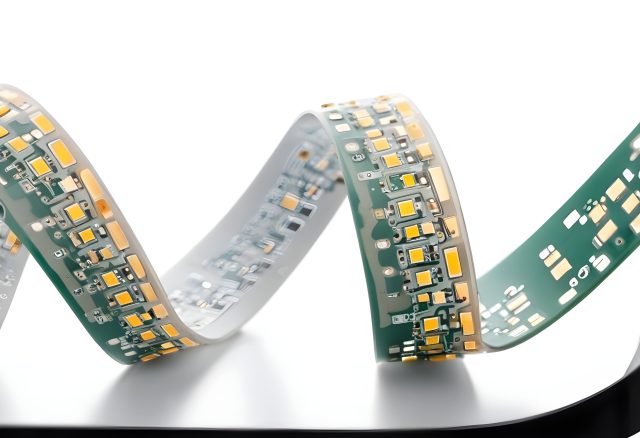

As LED technology continues to evolve toward miniaturization, higher brightness, and complex installation environments, traditional rigid PCBs can no longer meet all structural and thermal requirements.

This is why Flexible LED PCBs have become a core enabling technology in modern lighting and electronic design.

Flexible LED PCBs combine:

-

Mechanical flexibility for curved or dynamic installations

-

Efficient thermal paths for LED heat dissipation

-

Lightweight structure for compact products

-

High reliability under vibration and bending stress

Because of these advantages, they are now widely used in:

-

LED strip lighting and architectural illumination

-

Automotive ambient and signal lighting

-

Wearable and portable electronics

-

Medical lighting systems

-

Aerospace and high-reliability electronics

Choosing the right material system is the key factor that determines whether a flexible LED PCB will succeed in real-world applications.

1. Structure of a Flexible LED PCB

A typical flexible LED PCB is a multi-layer functional stack-up, where each layer directly affects performance, lifetime, and manufacturability.

Base Substrate Layer

The base layer provides mechanical support and electrical insulation.

Common materials:

-

Polyimide (PI) – industry standard for flexibility and heat resistance

-

FR-4 – limited bending, used in semi-flex designs

-

Insulated Metal Substrate (IMS) – superior thermal conductivity for high-power LEDs

Key requirements:

-

Stable dielectric properties

-

High temperature endurance

-

Resistance to mechanical fatigue

Conductive Copper Layer

Copper forms the current-carrying network of the LED circuit.

Material options:

-

Rolled Annealed (RA) copper → excellent ductility for dynamic bending

-

Electrodeposited (ED) copper → suitable for static or dense routing

Copper thickness must balance:

current capacity vs. flexibility vs. heat spreading.

Solder Mask & Protective Layers

Functions:

-

Prevent short circuits and oxidation

-

Improve environmental resistance

-

Enhance electrical insulation

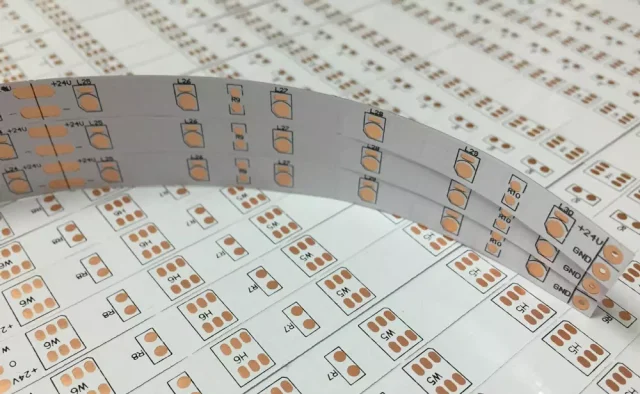

Flexible LED PCBs often use white solder mask to improve LED light reflection efficiency.

Coverlay / Silkscreen

-

Polyimide coverlay protects copper during bending

-

Silkscreen legend supports assembly accuracy and maintenance

2. Core Material Options for Flexible LED PCBs

Polyimide (PI) Substrate – The Industry Standard

Why PI dominates flexible LED PCB design:

-

Continuous high-temperature resistance (>260 °C)

-

Excellent electrical insulation

-

Strong mechanical toughness and tear resistance

-

Long flex life under repeated bending

PI is the default choice for automotive, medical, and industrial LED systems.

Adhesive Systems in Flexible Laminates

Bonding layers determine delamination resistance and thermal aging.

Common adhesive chemistries:

-

Acrylic → economical, moderate heat resistance

-

Modified epoxy → stronger bonding

-

PI resin → best high-temperature reliability

Adhesive-less laminates are increasingly used for:

-

Better thermal performance

-

Higher dimensional stability

-

Improved flex endurance

Advanced Copper Foil Technologies

RA Copper

Best for:

-

Dynamic bending LED strips

-

Foldable or wearable lighting

-

Long flex-cycle reliability

ED Copper

Best for:

-

Static installations

-

Fine-line, high-density routing

-

Cost-sensitive designs

Correct copper selection directly impacts field failure rate.

Liquid Crystal Polymer (LCP) for High-End Designs

LCP is emerging in next-generation flexible electronics.

Advantages:

-

Ultra-low moisture absorption

-

Very low dielectric loss → suitable for RF/high-speed signals

-

Excellent thermal stability

Used in:

-

Smart lighting with wireless modules

-

High-frequency LED control circuits

-

Aerospace electronics

Halogen-Free & Eco-Friendly Materials

Global regulations require:

-

RoHS compliance

-

WEEE environmental safety

Halogen-free materials:

-

Reduce toxic emissions during fire

-

Maintain flame-retardant performance

-

Support sustainable manufacturing goals

Photosensitive PI Cover Film

Enables:

-

High-density fine-line routing

-

Precise openings for SMD LEDs

-

Improved bonding strength

Critical for mini LED and micro-LED flexible boards.

Conductive Silver Paste Applications

Used when:

-

Traditional copper etching is impractical

-

Ultra-thin flexible circuits are required

-

Low-current signal paths dominate

Common in RFID, sensors, and specialty LED modules.

3. Engineering Factors in Material Selection

Electrical Performance

Key parameters:

-

Dielectric constant (Dk)

-

Dissipation factor (Df)

Low Dk/Df ensures:

-

Stable signal transmission

-

Reduced energy loss

-

Better EMI control

Thermal Management

LED reliability depends heavily on junction temperature control.

Important metrics:

-

Thermal conductivity

-

Glass transition temperature (Tg)

-

Coefficient of thermal expansion (CTE)

Poor thermal design leads to:

lumen decay, color shift, and early failure.

Mechanical Reliability

Flexible LED PCBs must survive:

-

Continuous bending

-

Vibration

-

Thermal cycling

Material fatigue resistance determines service lifetime.

Chemical & Environmental Resistance

Materials must tolerate:

-

Flux residues

-

Cleaning solvents

-

Humidity and corrosion

Essential for automotive and outdoor lighting.

Cost-Performance Balance

Engineering optimization is always:

Not themost expensive material — but the most suitable one.

Correct selection reduces:

-

Overdesign cost

-

Warranty risk

-

Production failure rate

4. Future Trends in Flexible LED PCB Materials

Industry development is moving toward:

-

Ultra-thin adhesive-less PI laminates

-

High-thermal-conductivity flexible substrates

-

Integration with smart control electronics

-

Sustainable, recyclable material systems

Flexible LED PCBs will remain critical infrastructure for next-generation lighting and smart devices.

Conclusion

Flexible LED PCBs deliver a powerful combination of:

-

Flexibility

-

Lightweight structure

-

Thermal efficiency

-

Long-term reliability

By carefully selecting PI substrates, advanced copper foils, LCP materials, and environmentally compliant components, engineers can significantly improve LED performance and durability.

As LED applications continue expanding across automotive, medical, industrial, and consumer electronics, material innovation in flexible PCBs will play an increasingly decisive role.