As modern electronics move toward higher data rates, higher frequencies, and more compact designs, signal integrity becomes a critical factor in PCB performance. In many applications, traditional FR4 materials may not meet the electrical requirements due to higher signal attenuation and unstable dielectric behavior.

That’s why low loss materials are increasingly used in advanced PCB designs. These materials help reduce signal loss, improve impedance stability, and ensure reliable performance in high-speed and high-frequency environments.

In this article, we will explain what low loss materials are, their key benefits, typical applications, and how to choose the right material for your PCB project.

What Are Low Loss Materials?

Low loss materials refer to PCB laminates with a low dissipation factor (Df), which means they have minimal dielectric loss when transmitting signals. Lower Df results in less signal energy being converted into heat, especially at higher frequencies.

Compared with standard FR4, low loss materials offer:

-

Lower insertion loss

-

Better signal integrity

-

More stable impedance control

-

Improved performance in high-speed and RF applications

Low loss materials are widely used in industries such as telecom, automotive, aerospace, and data communication.

Why Low Loss Materials Matter in PCB Design

When signals travel through PCB traces at high frequency or high speed, loss becomes a major concern. Excessive loss can lead to:

-

Weaker signal amplitude

-

Increased bit error rate

-

Reduced transmission distance

-

Poor RF efficiency

-

Unstable system performance

Low loss materials help solve these issues by providing a more stable electrical environment for high-performance signals.

Key Benefits of Low Loss Materials

1. Reduced Signal Attenuation

Low loss materials significantly reduce signal attenuation, which is especially important for:

-

Long trace routing

-

High-speed backplanes

-

High-frequency RF transmission lines

This results in cleaner signals and better overall system efficiency.

2. Improved Signal Integrity

Low loss laminates help minimize:

-

Distortion

-

Crosstalk

-

Jitter

-

Reflection

This makes them ideal for high-speed digital designs where timing and waveform quality are critical.

3. Better Performance at High Frequencies

At higher frequencies, FR4 may suffer from higher dielectric loss and unstable Dk values. Low loss materials provide better stability and repeatability, supporting applications such as:

-

Microwave circuits

-

5G modules

-

High-frequency antennas

4. Stable Dielectric Constant (Dk)

Many low loss materials also feature stable dielectric constant (Dk) across frequency and temperature changes. This supports:

-

Accurate impedance control

-

Consistent phase delay

-

Reliable RF matching

Typical Applications of Low Loss Materials

Low loss materials are widely used in high-performance electronics:

High-Speed Digital Systems

Low loss materials are commonly used in:

-

Data centers and servers

-

High-speed switches and routers

-

High-speed interconnect boards

-

PCIe and high-speed backplanes

They improve transmission quality at multi-gigabit speeds.

5G and Telecom Equipment

For telecom systems, low loss materials support:

-

Base station RF boards

-

Massive MIMO antennas

-

RF front-end modules

-

High-frequency filters and amplifiers

Automotive Radar and ADAS

Automotive applications often require stable performance under harsh conditions. Low loss materials are used in:

-

24GHz / 77GHz radar modules

-

Vehicle communication systems

-

Advanced driver assistance systems (ADAS)

Aerospace and Satellite Communication

Low loss materials help ensure stable signal performance for:

-

Satellite RF modules

-

Radar and navigation systems

-

High-reliability microwave circuits

Low Loss Materials vs Standard FR4

Standard FR4 is suitable for general electronics, but may not be ideal for high-speed or high-frequency designs.

| Feature | Standard FR4 | Low Loss Materials |

|---|---|---|

| Dielectric Loss (Df) | Higher | Lower |

| High-Frequency Performance | Limited | Excellent |

| Signal Integrity | Moderate | Strong |

| Impedance Stability | Less stable | More stable |

| Typical Use | General PCBs | RF / High-Speed PCBs |

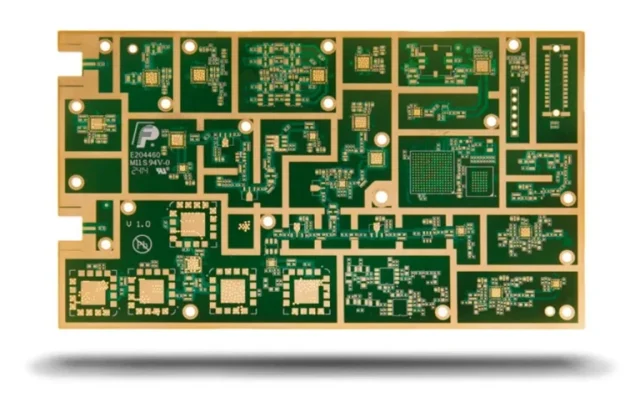

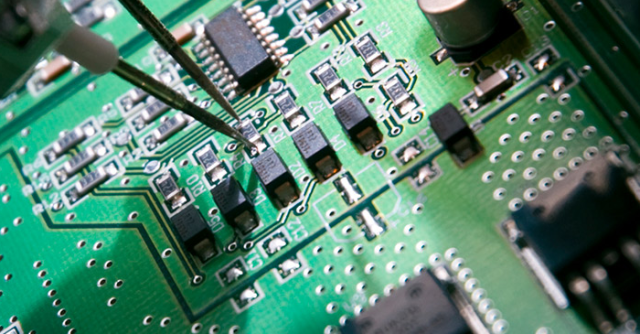

Manufacturing Considerations for Low Loss Materials

Producing PCBs with low loss materials requires strict control to ensure electrical performance and yield. Key factors include:

-

Controlled impedance stack-up planning

-

Precise etching for trace accuracy

-

Material handling and storage

-

Lamination process stability

-

Surface finish selection for RF performance

-

Testing for impedance and insertion loss

Working with an experienced PCB manufacturer can help prevent performance deviations and reduce project risk.

How to Choose the Right Low Loss Material

When selecting low loss materials, consider:

-

Frequency range and data rate requirements

-

Df and Dk targets

-

Layer count and stack-up structure

-

Thermal performance and reliability needs

-

Cost and lead time requirements

-

Compatibility with assembly processes

For RF designs, low loss materials are often selected based on both electrical performance and mechanical stability.

Conclusion

Low loss materials play a critical role in high-speed and high-frequency PCB designs. By reducing dielectric loss and improving signal integrity, they help ensure stable performance for applications such as 5G, automotive radar, data centers, and advanced communication systems.

If your project requires low insertion loss, controlled impedance, and reliable high-frequency performance, low loss materials are the ideal choice for your PCB design.