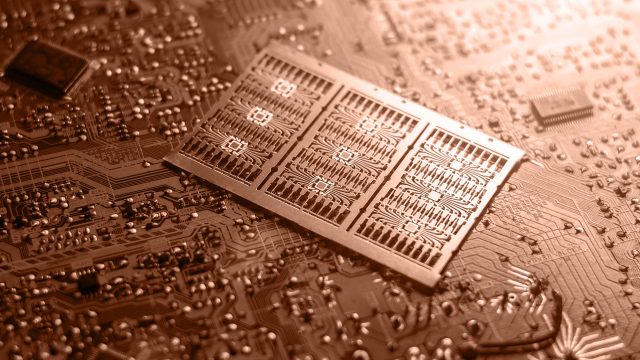

What Is a Heavy Copper PCB?

A Heavy Copper PCB is a printed circuit board that uses thick copper layers, typically ≥3 oz (105 μm) and up to 10 oz or more, to support high current, high power, and improved thermal performance. Heavy copper PCBs are widely used in power electronics, industrial control, automotive systems, and energy applications.

Compared with standard PCBs, heavy copper PCBs offer lower resistance, higher current capacity, and enhanced mechanical strength.

Key Characteristics of Heavy Copper PCB

A reliable Heavy Copper PCB features:

-

High current carrying capacity

Thick copper traces reduce resistance and voltage drop. -

Excellent thermal dissipation

Copper spreads heat efficiently. -

Improved mechanical durability

Thicker copper increases structural strength. -

Higher reliability in harsh environments

-

Support for high-power components

These characteristics make heavy copper PCB ideal for power-intensive designs.

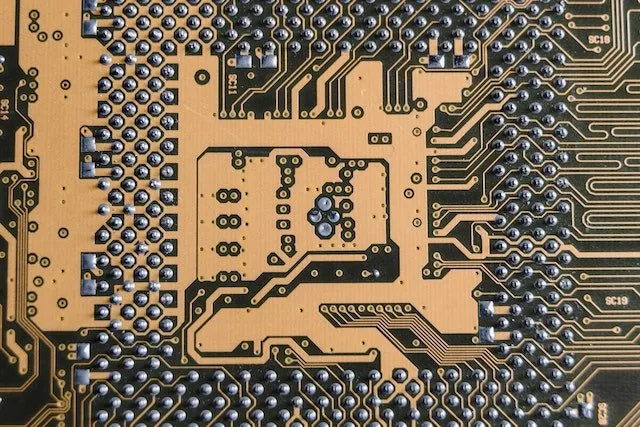

Copper Thickness Options

Typical copper weights for Heavy Copper PCBs include:

-

3 oz / 105 μm

-

4–6 oz / 140–210 μm

-

8–10 oz / 280–350 μm

-

Custom ultra-thick copper on request

Copper thickness is selected based on current, temperature rise, and design constraints.

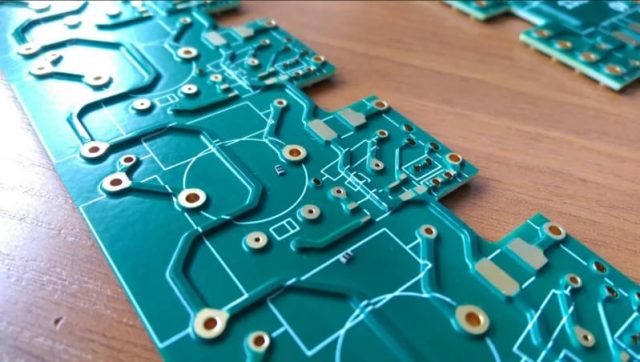

Manufacturing Challenges of Heavy Copper PCB

Manufacturing a Heavy Copper PCB requires specialized processes:

-

Advanced etching control

Maintains trace geometry with thick copper. -

Sequential plating and pattern plating

-

Precise lamination and resin filling

-

Controlled copper thickness uniformity

-

Electrical testing for high-current paths

Experience and process stability are critical to quality.

Advantages of Heavy Copper PCB

Using a Heavy Copper PCB provides key benefits:

-

Handles high current with minimal loss

-

Reduces overheating and thermal stress

-

Supports compact high-power designs

-

Improves long-term reliability

-

Suitable for demanding industrial and automotive use

Heavy copper PCBs are essential for power electronics.

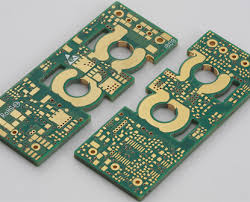

Applications of Heavy Copper PCB

Heavy Copper PCBs are commonly used in:

-

Power supplies and converters

-

Automotive power control units

-

Motor drives and inverters

-

Industrial automation systems

-

Energy storage and renewable energy equipment

-

Railway and transportation electronics

They are critical in high-power systems.

Heavy Copper PCB vs Standard PCB

Compared with standard copper PCBs, Heavy Copper PCBs offer:

-

Much higher current capacity

-

Better thermal performance

-

Improved mechanical strength

-

Higher reliability under stress

For power and industrial applications, heavy copper PCB is the preferred solution.

Conclusion

A Heavy Copper PCB is an ideal solution for high-current and high-power applications requiring robust performance and long-term reliability. With thick copper layers and specialized manufacturing processes, heavy copper PCBs deliver excellent electrical, thermal, and mechanical performance.

Choosing an experienced Heavy Copper PCB manufacturer ensures precise copper thickness control, consistent quality, and reliable operation in demanding environments.