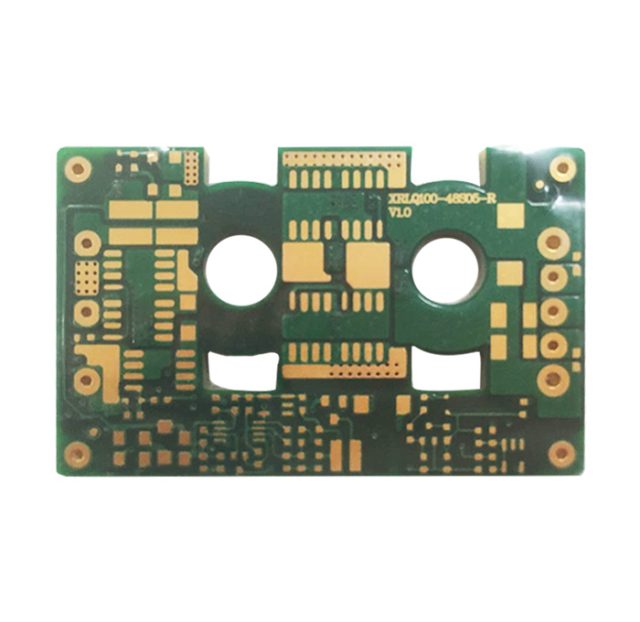

Power electronics continue to advance toward higher efficiency, greater power density, and more compact architectures. From industrial motor drives to renewable energy inverters and high-current battery systems, modern equipment demands circuit boards that can withstand extreme electrical and thermal stress. At the core of these high-power platforms is the Heavy Copper PCB, a specialized board engineered for high-current transmission, robust thermal performance, and long-term mechanical durability.

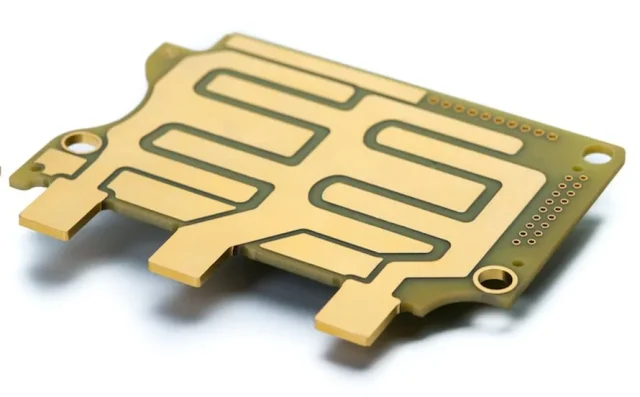

A Heavy Copper PCB typically features copper thicknesses of 2 oz/ft² (70 μm) to more than 20 oz/ft² (700 μm). This expanded copper volume allows the board to safely carry large currents, dissipate heat effectively, and maintain structural reliability in harsh industrial environments.

Why Heavy Copper PCBs Are Critical to Power Electronics

The growing adoption of electric vehicles, energy storage systems, and high-efficiency power converters requires PCBs that go far beyond the capabilities of standard 1 oz–1.5 oz designs. Key performance benefits include:

High-current handling capability

Thick copper traces reduce resistive losses, enable stable current flow, and minimize temperature rise under continuous heavy loads. This is crucial for traction systems, DC–DC converters, and high-power motor drivers.

Superior thermal dissipation

By distributing heat more evenly across the board, Heavy Copper PCBs protect components from thermal fatigue. Combined with thermal vias and copper planes, they help maintain junction temperature stability in demanding applications.

Enhanced mechanical robustness

The increased copper thickness reinforces traces, vias, and connection points, reducing the risk of cracking or delamination under vibration, thermal cycling, or long-term electrical stress.

Reliable high-power interconnects

Wide traces, plated busbars, and embedded copper structures support high-current pathways with low impedance and long service life.

Typical Applications of Heavy Copper PCBs

As industries shift toward electrification and digitalization, Heavy Copper PCBs have become essential in many high-power systems:

1. Industrial Power Converters

IGBT drivers, power inverters, and AC/DC converters rely on thick copper to manage rapid switching loads and high-power transients.

2. Energy Storage Systems and Battery Management

Stable high-current paths are critical for charging, discharging, and cell-balancing circuits.

3. Automotive Powertrains

Electric vehicle onboard chargers, motor controllers, and high-voltage distribution assemblies depend on reliable thermal and electrical performance.

4. Renewable Energy Equipment

Solar inverters and wind energy converters require robust, long-life PCB platforms for outdoor and high-load conditions.

5. High-Current Motor Control

Industrial robotics, CNC machines, and HVAC systems use Heavy Copper PCBs to ensure consistent torque and speed control.

Engineering Requirements for Heavy Copper PCB Design

To maintain safety, reliability, and manufacturability, certain engineering principles must be followed:

Trace geometry and copper distribution

Wider traces and optimized copper balancing prevent warpage and ensure predictable thermal behavior.

Heat spreading layers

Thick copper planes and thermal vias aid in controlling heat gradients across the board.

High-reliability plating

Uniform plating in through-holes and vias is crucial to avoid cracking under high current or temperature cycles.

Material selection

High Tg (glass transition temperature), low CTE (coefficient of thermal expansion), and high thermal conductivity laminates support long-term reliability under heavy electrical loads.

KKPCB’s Manufacturing Advantages for Heavy Copper PCBs

KKPCB offers specialized heavy-copper fabrication optimized for industrial power systems and automotive-grade applications. Our capabilities include:

• Copper thickness from 2 oz to 20 oz

• Precision etching for wide and ultra-thick traces

• Multi-layer heavy copper stackups for compact power modules

• Reinforced vias for high-current interconnects

• Automated inspection for plating uniformity and mechanical stability

• High-Tg materials to withstand thermal cycling and high-power loads

With rigorous process control and extensive high-current engineering expertise, KKPCB ensures each Heavy Copper PCB provides stable performance, extended service life, and safety compliance across extreme operating conditions.

Powering the Next Generation of High-Energy Systems

As global industries accelerate electrification—from EVs to renewable infrastructure—the demand for durable and thermally stable Heavy Copper PCBs will continue to rise. With deep manufacturing capability and engineering support, KKPCB delivers thick-copper solutions that reinforce the backbone of modern power electronics.