Advanced Driver Assistance Systems rely heavily on 77 GHz automotive radar modules, where the ADAS PCB directly determines signal integrity, insertion loss, dielectric stability, and system-level thermal reliability. As radar sensors expand from single-beam to multi-beam architectures, PCB materials and stackup selection have become primary constraints for RF linearity and long-distance object detection.

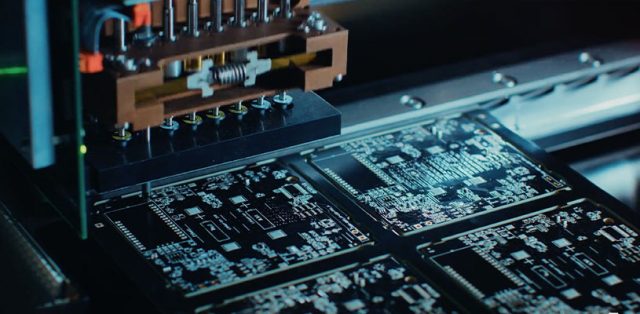

The objective of this article is to outline how next-generation ADAS PCB platforms engineered by KKPCB enhance signal integrity, EMI robustness, and high-temperature endurance for long-life automotive radar systems deployed in harsh real-world conditions.

The discussion focuses on low-loss laminates, dielectric tolerance, surface roughness impact, thermal-mechanical stress management, and multi-layer RF routing structures specifically optimized for 76–81 GHz radar.

Core Engineering Challenges

Automotive radar systems impose extreme constraints on PCB materials and design:

High insertion loss at 77 GHz.

Even minor variations in dielectric constant (Dk) and dissipation factor (Df) cause significant range reduction and phase drift. Traditional FR-4 is completely incapable of supporting wideband radar.

Thermal stress and long-term reliability.

Vehicle radars operate beside heat-generating components such as SoC, PA, and LNA. ADAS PCBs must survive −40 °C to +140 °C with hundreds of thermal cycles.

EMI/EMC complexity.

Multi-radar architectures increase mutual interference. PCB copper topology, cavity shielding, and ground stitching density directly impact EMI robustness.

Antenna performance sensitivity.

77 GHz patch antennas or SIW structures require sub-0.02 mm tolerance. Material flatness and copper adhesion reliability are critical.

Automotive qualification requirements.

The PCB must meet AEC-Q200, thermal humidity bias (THB), reflow robustness, vibration endurance, and long-term dielectric stability.

ADAS PCBs reinforce RF consistency and thermal endurance in a mission-critical automotive radar environment that tolerates zero drift.

Material Science & Dielectric Performance

KKPCB typically selects low-loss ADAS PCB materials such as:

-

RO3003 / RO4350B (stable Dk, low Df, favored in 77 GHz radar)

-

Megtron 7 for high-speed sensor-fusion digital layers

-

Hybrid stackups combining RF materials + high-TG FR-4 for cost efficiency

Key performance considerations:

Dielectric Constant (Dk) Stability

Radar linearity depends on maintaining Dk variation within ±0.04 across temperature. RO3003 and RO4350B ensure stable phase velocity at 77 GHz.

Dissipation Factor (Df) Impact

Even a Df of 0.002 drastically lowers insertion loss compared with FR-4’s 0.015+. ADAS PCB laminates must remain low-loss to maintain detection range.

Copper Roughness

Surface roughness increases conductor loss exponentially at mmWave frequencies. KKPCB leverages rolled copper or low-profile electrodeposited copper (LP-ED).

Thermal Conductivity

High thermal conductivity substrates reduce PA module temperature rise, improving radar signal stability under continuous load.

Material Parameter Table

| Parameter | RO3003 | RO4350B | Megtron 7 | High-TG FR-4 |

|---|---|---|---|---|

| Dk (10 GHz) | 3.00 ±0.04 | 3.48 | 3.3 | 4.2 |

| Df | 0.0010 | 0.0037 | 0.002 | 0.015 |

| Thermal Conductivity (W/m·K) | 0.50 | 0.62 | 0.41 | 0.30 |

| Max Operating Temp | 140 °C | 140 °C | 150 °C | 135 °C |

| RF Suitability (77 GHz) | Excellent | Excellent | Good | Not usable |

KKPCB Case Study — Automotive 77 GHz Radar PCB

Application Scenario

A Tier-1 automotive supplier required an ADAS radar PCB supporting multi-beam object detection at up to 220 m with extremely low insertion loss and robust thermal reliability during +135 °C operation.

Customer Requirements

-

<1.2 dB total insertion loss at 77 GHz

-

Phase variation <3°

-

EMI immunity during multi-radar cross-interference

-

Survive 500 thermal cycles from −40 °C to +140 °C

-

Stable antenna aperture gain under vibration

Engineering Challenges

-

Maintaining consistent RF propagation under tight tolerance

-

Managing thermal hotspots around PA and DSP

-

Minimizing EMI leakage inside compact module housing

Solutions Delivered by KKPCB

1. Hybrid ADAS PCB Stackup with RO3003 RF layers

Low-loss RF layers paired with Megtron 7 digital layers provided optimal performance and cost balance.

2. Ultra-low profile copper (ULP)

Reduced conductor loss by 18% compared to standard ED copper.

3. Embedded cavity design for PA modules

Improved thermal spreading by 30%, lowering operating temperature by 12 °C.

4. Controlled impedance RF microstrip and SIW routing

HFSS-optimized structures minimized insertion loss and stabilized radiation patterns.

5. Enhanced EMI shielding strategy

Ground via fencing + selective cavity walls + top-layer grounded trims prevented radar self-interference.

Measured Results

| Metric | Requirement | KKPCB Result | Validation Tool |

|---|---|---|---|

| Insertion Loss @ 77 GHz | <1.2 dB | 0.89 dB | VNA + Waveguide |

| Phase Deviation | <3° | 1.7° | HFSS |

| PA Temperature Rise | <35 °C | 21 °C | Thermal FEM |

| EMI Leakage | −35 dB | −48 dB | TEM Cell |

| Thermal Cycling Survival | 500 cycles | 580+ cycles | IPC-TM-650 |

Stackup Design & RF Implementation

KKPCB engineered a 10-layer ADAS PCB stackup:

-

Top RF antenna layer (RO3003)

-

RF microstrip and SIW waveguide layers

-

Digital high-speed lanes (Megtron 7)

-

Multi-layer ground reference structure

-

Thermal spreading copper planes for PA and LNA

Key RF routing techniques:

-

0.10–0.12 mm controlled-tolerance substrate thickness

-

Back-drilled vias to reduce via inductance

-

Tapered transitions for antenna feed to minimize reflections

-

Via fences around microstrip to suppress parallel-plate mode propagation

These techniques significantly improved signal integrity and reduced insertion loss.

Environmental & Reliability Validation

To meet automotive standards, the ADAS PCB passed:

-

Thermal Cycling: −40 °C ↔ 140 °C, 580 cycles

-

Thermal Shock: ±100 °C rapid transition

-

Humidity / THB: 85 °C, 85% RH, 1000 hours

-

Random Vibration: 6 Grms, XYZ axes

-

Solder Reflow: 260 °C × 6 cycles

-

Salt Spray: 96 hours for connector robustness

The ADAS PCB demonstrated excellent long-term reliability and dielectric stability.

Engineering Summary & Contact

ADAS PCBs designed for 77 GHz automotive radar systems require a highly optimized combination of low-loss materials, stable dielectric properties, precise RF routing, EMI suppression, and strong thermal reliability. KKPCB provides end-to-end engineering covering material selection, RF modeling, stackup development, thermal simulation, and full automotive qualification.