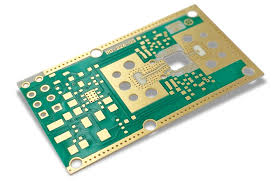

Multi-band wireless modules are moving toward increasingly complex RF transceiver architectures, supporting simultaneous operation across sub-6 GHz, C-band, and mmWave channels. As bandwidth expands and carrier aggregation becomes standard, the performance of the RF transceiver PCB becomes a controlling factor in overall system efficiency. Maintaining phase coherence, thermal stability, and low-loss RF routing requires PCB stackups engineered to handle high-frequency stress while preserving signal clarity across multiple operating bands.

Material Engineering for Low-Loss, Phase-Stable RF Routing

At the heart of any high-performance RF transceiver lies the dielectric material. Multi-band systems demand laminates with:

• Low Df (dissipation factor) for minimal insertion loss

• Stable Dk (dielectric constant) across temperature extremes

• Low roughness copper foils to suppress conductor loss at high frequencies

• Controlled thermal expansion to prevent phase drift

Materials commonly used in advanced RF transceiver PCB stackups include:

• Rogers RO4350B / RO4835

• PTFE-based laminates

• Hydrocarbon-ceramic composites

These materials offer predictable dielectric behavior, allowing RF designers to maintain precise impedance and phase alignment as operating frequencies rise above 6–40 GHz.

Stackup Architecture for Multi-Band Wireless Modules

A well-engineered RF PCB stackup determines the electrical behavior of every high-frequency trace. Multi-band modules benefit from:

• Microstrip and GCPW (grounded coplanar waveguide) structures

• Continuous reference ground planes for stable impedance

• Optimized dielectric thickness for phase-controlled propagation

• Blind and buried vias that minimize parasitic inductance

• Back-drilling to eliminate via stubs in high-frequency channels

These stackup strategies ensure clean S-parameters, tight phase matching between differential channels, and minimal mode conversion across all frequency bands.

Phase Coherence Across Multi-Band RF Paths

Phase coherence directly influences beamforming accuracy, MIMO performance, and synchronization within the RF transceiver. PCB-level factors that preserve coherence include:

• Identical electrical lengths across parallel RF paths

• Low-loss laminates that prevent amplitude imbalance

• Controlled-impedance routing for differential RF channels

• Material stability that prevents drift under thermal load

By stabilizing propagation velocity, the RF transceiver PCB becomes a predictable medium for timing-critical multi-band operations.

Thermal Stability in High-Power RF Modules

As output power and channel aggregation increase, thermal loading rises sharply. Without proper thermal management, RF gain, phase stability, and noise figure degrade. Satellite, base station, and IoT transceiver modules all require:

• High-conductivity copper planes

• Thermal vias beneath power amplifiers and mixers

• Ceramic-based substrates with superior heat spreading

• Balanced CTE to avoid stress fractures in multilayer boards

A thermally stable RF transceiver PCB stackup preserves RF calibration and long-term reliability even under continuous high-power operation.

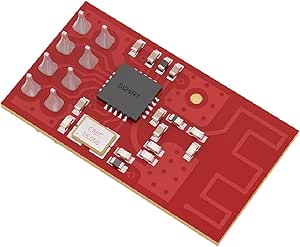

EMI Control and Signal Isolation in Dense RF Front Ends

Multi-band architectures pack PA, LNA, mixer, PLL, and digital control into limited PCB space. To maintain signal integrity, the board must provide:

• Via fences around high-frequency traces

• Segregated RF zones with independent ground returns

• Shielded cavities for sensitive LNAs

• Layered isolation between RF, IF, and digital logic

• Clean power delivery with low-noise DC rails

These isolation techniques prevent cross-band interference and maintain clean RF spectra across the module.

KKPCB’s Expertise in RF Transceiver PCB Manufacturing

KKPCB engineers advanced RF transceiver PCB stackups with:

• Tight impedance tolerances (±5% or better)

• Low-loss multilayer structures for 6–40 GHz operation

• Material-controlled stackups for phase-stable routing

• Precision RF fabrication (smooth foil, back-drill, microvias)

• Comprehensive DFM/DFR for industrial and telecom-grade reliability

Our manufacturing ensures that high-frequency routing remains stable from prototype through full-volume production.

Enabling the Future of Multi-Band Wireless Connectivity

As wireless modules evolve toward 5G/6G, massive MIMO, and ultra-wideband architectures, phase coherence and thermal stability will continue to define system performance. With engineered materials, RF-optimized stackups, and precise PCB fabrication, KKPCB delivers the RF transceiver PCB reliability required for next-generation communication platforms.