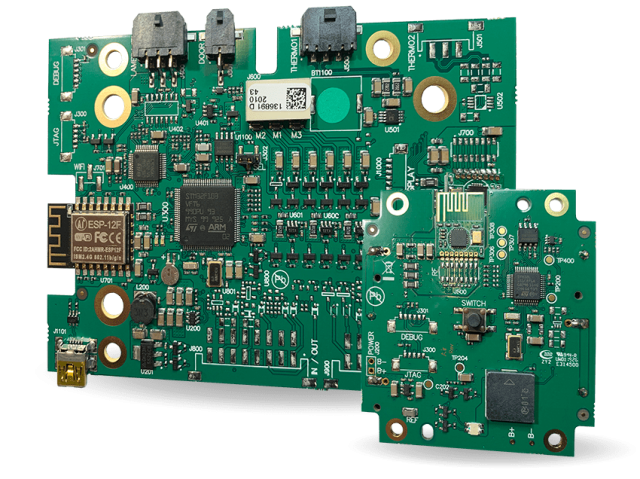

Automated Test Equipment (ATE) systems require test boards that deliver precise electrical performance and long-term reliability. A Custom ATE PCB is engineered specifically to match the electrical, mechanical, and functional requirements of each test platform, ensuring accurate and repeatable test results.

A well-designed custom ATE PCB plays a critical role in advanced semiconductor and electronic testing.

What Is a Custom ATE PCB?

A Custom ATE PCB is a purpose-built printed circuit board designed to interface directly with ATE systems. Unlike standard test boards, custom ATE PCBs are optimized for specific device types, signal counts, frequencies, and power requirements.

Why Customization Is Essential for ATE PCBs

Each ATE application has unique demands, including:

-

Different signal speeds and protocols

-

Multiple voltage and current domains

-

Mechanical interface constraints

Customization ensures the PCB precisely matches the test environment.

Signal Integrity Optimization in Custom ATE PCBs

Maintaining signal integrity is critical for accurate testing. Custom ATE PCBs incorporate:

-

Controlled impedance routing

-

Matched trace lengths for timing accuracy

-

Low-noise grounding structures

These techniques minimize distortion and measurement errors.

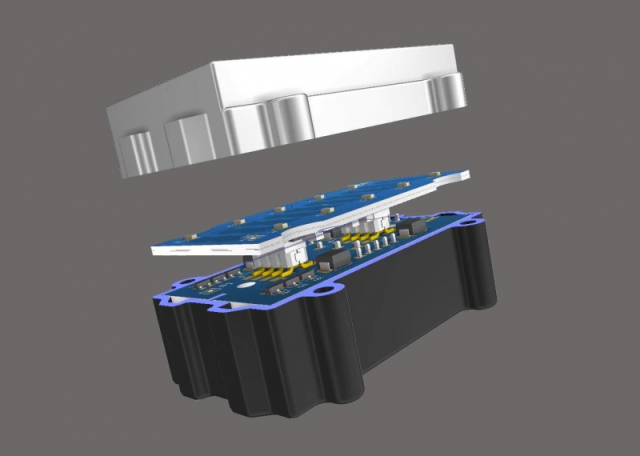

Power Integrity and High-Current Handling

ATE systems often require stable and high-current power delivery. Custom ATE PCBs feature:

-

Dedicated power planes

-

Low-resistance copper structures

-

Optimized decoupling and filtering

Reliable power delivery ensures consistent test performance.

Stackup Design and Layer Configuration

Custom ATE PCBs commonly use multilayer stackups to:

-

Separate signal and power domains

-

Reduce EMI and crosstalk

-

Improve mechanical strength

Careful stackup planning improves both electrical and mechanical reliability.

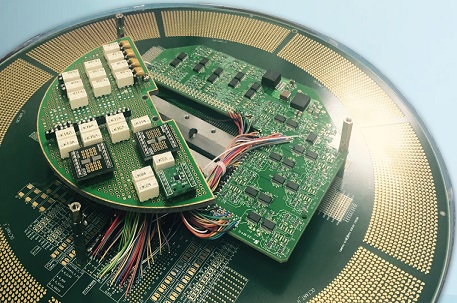

Connector, Socket, and Interface Integration

Custom ATE PCBs must support:

-

High-pin-count connectors

-

Test sockets and probe interfaces

-

Rigid mechanical tolerances

Accurate integration ensures stable contact and repeatable testing.

Material Selection for Test Accuracy

Depending on test frequency and environment, custom ATE PCBs may use:

-

High-Tg FR-4 for durability

-

Low-loss laminates for high-speed testing

-

Hybrid materials for balanced performance

Material choice directly affects signal quality.

Manufacturing Precision and Quality Assurance

Manufacturing custom ATE PCBs requires:

-

Tight dimensional control

-

Consistent copper thickness

-

Electrical and functional testing

Strict quality control ensures reliable test boards.

Applications of Custom ATE PCBs

Custom ATE PCBs are widely used in:

-

Semiconductor device testing

-

IC validation and characterization

-

Functional and parametric testing

-

Production and reliability testing systems

Each application benefits from tailored PCB solutions.

Selecting a Custom ATE PCB Manufacturer

When choosing a custom ATE PCB supplier, consider:

-

Experience with ATE and semiconductor test boards

-

Controlled impedance and power integrity expertise

-

Support for prototype and volume production

-

Engineering collaboration and DFM support

An experienced manufacturer reduces risk and accelerates deployment.

Conclusion

The Custom ATE PCB is a critical component in automated test equipment, enabling accurate, stable, and repeatable testing. Through customized design, optimized stackups, and precision manufacturing, custom ATE PCBs support advanced testing requirements across multiple industries.

Partnering with a specialized custom ATE PCB manufacturer ensures long-term reliability and consistent test performance.