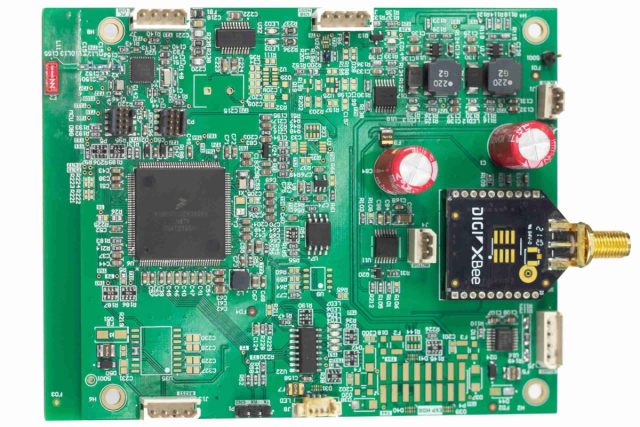

In automated semiconductor testing, accuracy must be maintained not just once—but across thousands of test cycles. A Custom ATE PCB is designed specifically to match the electrical, mechanical, and environmental requirements of each test platform, ensuring stable and repeatable test results over time.

A professionally engineered custom ATE PCB reduces false failures, improves yield, and supports efficient production testing.

Why Standard Test Boards Are Not Enough

Generic test boards often fail to meet ATE requirements because:

-

Signal speeds and pin counts vary widely

-

Power demand changes between device types

-

Mechanical interfaces differ across testers

A custom ATE PCB is built to match exact test conditions.

Signal Integrity Designed for Test Repeatability

Custom ATE PCBs are optimized to:

-

Maintain controlled impedance across all critical channels

-

Match signal path lengths for timing accuracy

-

Minimize reflections and crosstalk

These factors ensure consistent measurement results.

Power Integrity for High-Current and Multi-Voltage Testing

ATE environments often require:

-

Multiple voltage rails

-

High transient current capability

-

Low noise power delivery

Custom ATE PCBs use dedicated power planes, low-resistance copper, and optimized decoupling to maintain power stability.

Stackup Engineering and Layer Allocation

Custom ATE PCBs typically use multilayer stackups to:

-

Separate high-speed signals from noisy power paths

-

Improve EMI control

-

Enhance mechanical rigidity

Careful layer planning improves electrical performance and manufacturability.

Connector, Socket, and Interface Precision

ATE PCBs must reliably support:

-

High-pin-count connectors

-

Test sockets and probe interfaces

-

Repeated insertion cycles

Mechanical accuracy ensures stable electrical contact over time.

Material Selection for Durability and Stability

Depending on test conditions, custom ATE PCBs may use:

-

High-Tg FR-4 for thermal durability

-

Low-loss materials for high-speed testing

-

Hybrid stackups for cost-effective performance

Material stability directly impacts long-term reliability.

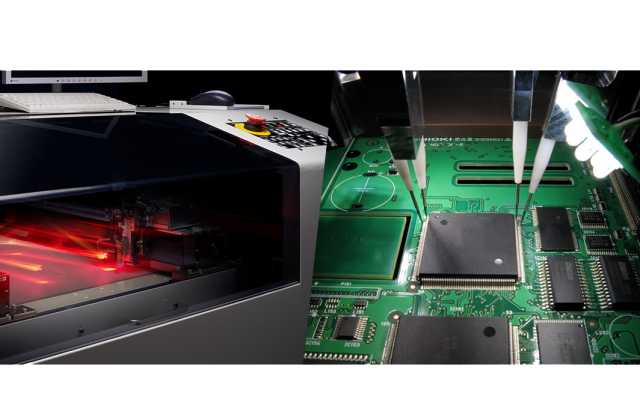

Assembly and Quality Verification

Custom ATE PCBs undergo:

-

Precision assembly for connectors and sockets

-

Electrical and functional testing

-

Impedance verification on critical signal paths

These steps ensure consistent test board performance.

Applications of Custom ATE PCBs

Custom ATE PCBs are widely used in:

-

Semiconductor production testing

-

IC validation and characterization

-

Functional and parametric testing

-

Reliability and stress testing systems

Each application benefits from tailored PCB solutions.

Choosing a Custom ATE PCB Manufacturing Partner

When selecting a custom ATE PCB manufacturer, consider:

-

Experience with ATE and semiconductor test systems

-

High-pin-count and controlled impedance capability

-

Support for engineering prototypes and volume builds

-

Strong DFM and test-oriented engineering support

A capable partner improves test efficiency and reduces risk.

Conclusion

The Custom ATE PCB is a foundational element of reliable automated testing. Through precise engineering, stable power delivery, and robust mechanical design, custom ATE PCBs ensure consistent test results from early validation through mass production.

Partnering with an experienced custom ATE PCB manufacturer ensures long-term test stability and manufacturing confidence.