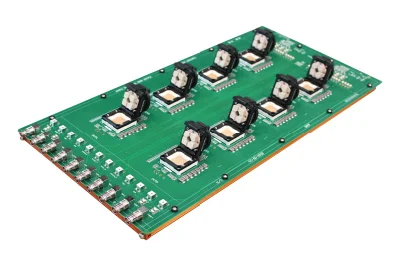

What Is a Burn-in PCB?

A Burn-in PCB is a specialized printed circuit board used for burn-in testing and stress screening, where electronic components or assemblies are operated under elevated temperature, voltage, and current conditions for extended periods. The goal of a Burn-in PCB is to identify early-life failures and improve long-term product reliability.

Burn-in PCBs are widely used in semiconductor manufacturing, automotive electronics, industrial control, and high-reliability systems.

Key Requirements for Burn-in PCB

A reliable Burn-in PCB must meet strict performance and durability requirements:

-

High temperature resistance

Stable operation at elevated temperatures for long durations. -

High current handling capability

Supports continuous power stress. -

Excellent mechanical strength

Withstands repeated insertion and removal cycles. -

Reliable electrical connections

Ensures stable contact during long test hours. -

Long-term stability and repeatability

These requirements distinguish Burn-in PCBs from standard test boards.

Material Selection for Burn-in PCB

Material choice directly affects Burn-in PCB reliability:

-

High-Tg FR-4 or enhanced epoxy materials

For elevated temperature endurance. -

Heavy copper layers

Support high current paths and heat dissipation. -

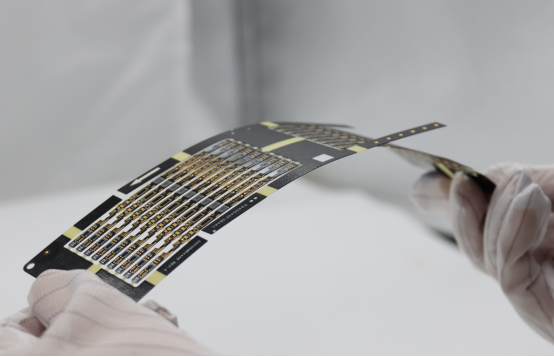

Polyimide materials

For extreme temperature and long-term stability. -

Ceramic substrates (Alumina)

For high-power or high-temperature applications.

Material selection depends on test conditions and stress profiles.

Design Considerations for Burn-in PCB

Effective Burn-in PCB design focuses on durability and stability:

-

Wider traces and thicker copper

-

Optimized power distribution

-

Robust via structures

-

Socket and connector reinforcement

-

Thermal management features

-

Redundant grounding and power paths

These design choices ensure safe and reliable stress testing.

Manufacturing Challenges of Burn-in PCB

Producing a Burn-in PCB requires specialized manufacturing expertise:

-

Consistent copper thickness control

-

High-temperature lamination processes

-

Strong solder mask adhesion

-

Reliable plating and via integrity

-

Extensive electrical testing

Quality issues can lead to test instability or false failures.

Advantages of Professional Burn-in PCB Manufacturing

Partnering with an experienced Burn-in PCB manufacturer provides:

-

Stable performance under extreme conditions

-

Long service life and reusability

-

Reduced downtime during testing

-

Consistent and repeatable test results

-

Support for custom burn-in fixtures

These advantages are essential in production test environments.

Applications of Burn-in PCB

Burn-in PCBs are commonly used in:

-

Semiconductor burn-in systems

-

IC package and module reliability testing

-

Automotive electronics stress testing

-

Industrial and power electronics validation

-

Production-level quality screening

They play a critical role in ensuring product reliability.

Conclusion

A Burn-in PCB is a critical tool for reliability verification and early-failure detection. By withstanding high temperature, high current, and long operating cycles, Burn-in PCBs help ensure that only reliable products reach the market.

Choosing a qualified Burn-in PCB manufacturer ensures durable design, stable performance, and dependable results in demanding burn-in and stress test applications.