Automotive radar systems are a core technology in modern vehicles, enabling advanced driver-assistance systems (ADAS) and autonomous driving features. At the heart of these systems lies the automotive radar PCB, which must deliver stable mmWave performance, ultra-low signal loss, and long-term reliability under harsh automotive environments.

Professional automotive radar PCB manufacturing combines advanced RF materials, precise impedance control, and automotive-grade quality standards to meet the demanding requirements of 77GHz and 79GHz radar applications.

What Is Automotive Radar PCB Manufacturing?

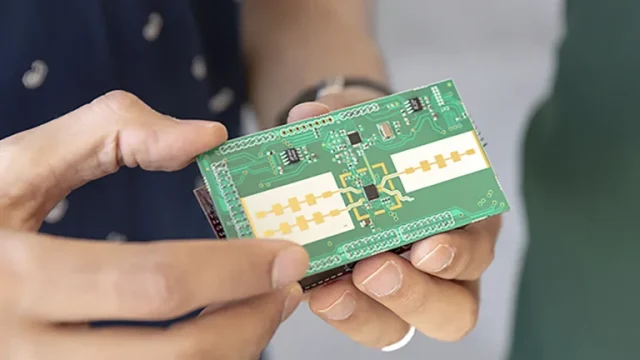

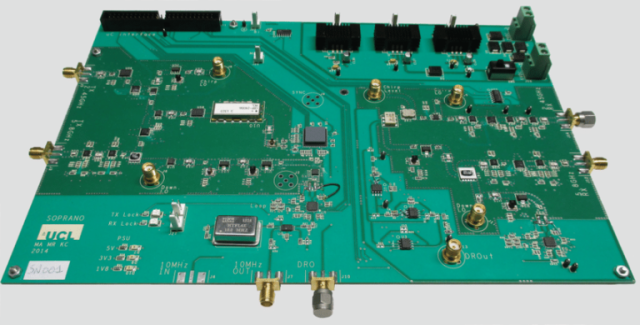

Automotive radar PCB manufacturing refers to the fabrication of high-frequency PCBs used in vehicle radar modules, typically operating at 24GHz, 77GHz, or 79GHz. These PCBs integrate RF front-end circuits, antennas, and signal processing paths.

Key requirements include:

-

mmWave signal integrity

-

Controlled impedance routing

-

Low dielectric and conductor loss

-

Thermal and mechanical stability

-

Automotive reliability compliance

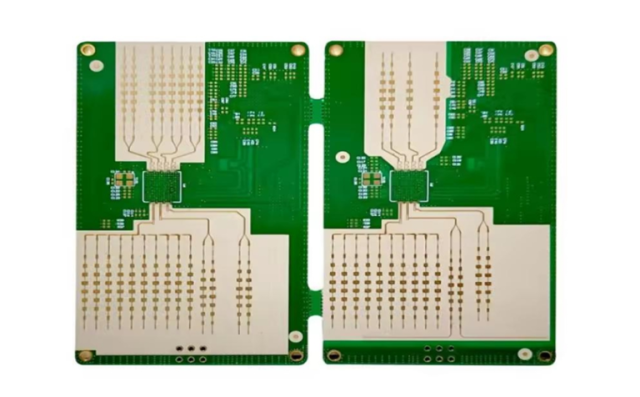

Key Materials for Automotive Radar PCBs

A professional automotive radar PCB manufacturer supports advanced RF materials such as:

-

Rogers RO3003 / RO3006 / RO4003 series

-

Rogers RT/duroid 5880 and 5870

-

Taconic RF-35 and TLY series

-

Hybrid RF + FR-4 stackups

Material selection is critical to achieving low loss and stable dielectric performance at mmWave frequencies.

Controlled Impedance and mmWave Performance

Automotive radar PCBs require precise impedance control to ensure accurate signal transmission and reflection suppression. Manufacturing processes typically include:

-

Stackup simulation and impedance modeling

-

Tight control of dielectric thickness and trace geometry

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance measurement and validation

Accurate impedance control is essential for radar resolution and detection accuracy.

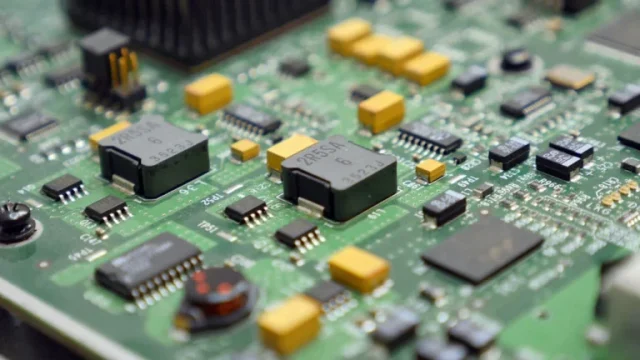

Manufacturing Challenges in Automotive Radar PCB Production

Automotive radar PCB manufacturing presents unique challenges, including:

-

Fine-line etching for mmWave RF traces

-

Copper surface roughness control to reduce conductor loss

-

Specialized drilling and via plating for PTFE materials

-

Stable lamination for multilayer radar PCBs

Only experienced RF manufacturers can consistently meet these requirements.

Automotive-Grade Quality and Reliability

A qualified automotive radar PCB manufacturer implements:

-

AOI and electrical testing

-

RF impedance and insertion loss verification

-

Thermal cycling and reliability inspection

-

Process traceability and quality documentation

These measures ensure compliance with automotive reliability expectations.

Applications of Automotive Radar PCBs

Automotive radar PCBs are widely used in:

-

Adaptive cruise control (ACC)

-

Automatic emergency braking (AEB)

-

Blind spot detection (BSD)

-

Parking and short-range radar

-

Autonomous driving sensor fusion systems

Each application demands stable mmWave performance and high reliability.

Prototype to Mass Production Capability

A professional automotive radar PCB manufacturing partner supports:

-

Rapid radar PCB prototyping

-

Small batch and pilot production

-

Automotive-grade mass production

-

Engineering support and DFM optimization

This ensures smooth scaling from R&D to vehicle-level deployment.

How to Choose an Automotive Radar PCB Manufacturer

When selecting a automotive radar PCB manufacturing partner, consider:

-

Experience with mmWave and radar PCB projects

-

RF material handling and impedance control capability

-

Automotive quality management systems

-

Production capacity and delivery stability

-

Engineering communication and technical support

The right manufacturer reduces risk and ensures long-term supply reliability.

Conclusion

Automotive radar PCB manufacturing plays a critical role in enabling reliable ADAS and autonomous driving systems. By combining low-loss RF materials, precise impedance control, and automotive-grade quality processes, radar PCBs deliver stable performance at 77GHz and 79GHz.

Partnering with an experienced automotive radar PCB manufacturer ensures your radar modules meet performance, reliability, and production scalability requirements.