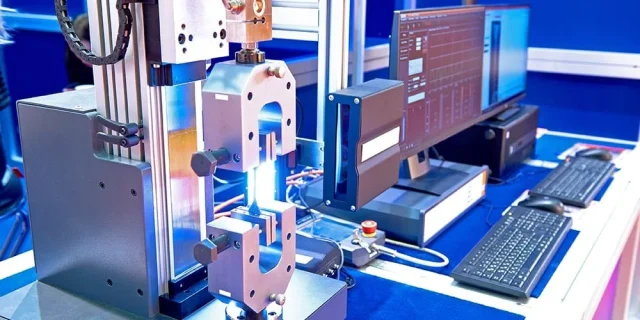

In modern semiconductor manufacturing, Automated Test Equipment (ATE) plays a critical role in verifying the performance, reliability, and functionality of integrated circuits. At the core of every ATE system is the Automated Test Equipment PCB, which serves as the electrical interface between the test system and the device under test (DUT).

An ATE PCB must deliver high-speed signal integrity, precise impedance control, and mechanical reliability to support accurate and repeatable test results across high-volume production environments.

What Is an Automated Test Equipment PCB?

An Automated Test Equipment PCB is a specialized printed circuit board designed for semiconductor testing applications. It is commonly used as a load board, interface board, or test fixture within ATE platforms.

Compared with standard PCBs, ATE PCBs must handle:

-

High-speed digital signals

-

High-frequency RF and microwave signals

-

High pin count device interfaces

-

Repeated mechanical insertion and test cycles

Key Performance Requirements of ATE PCBs

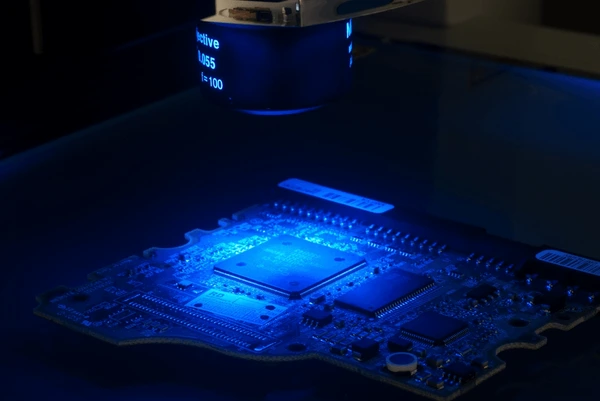

High-Speed Signal Integrity

ATE PCBs must support multi-Gbps data rates with minimal signal degradation, ensuring accurate timing and data integrity during IC testing.

Controlled Impedance

Precise impedance control is essential for reducing reflections, crosstalk, and noise in high-speed and high-frequency test environments.

High Pin Count Capability

Modern ICs feature dense I/O configurations, requiring fine-line routing, HDI technology, and multilayer PCB structures.

Reliability and Durability

ATE PCBs are subject to repeated test cycles, making mechanical strength and long-term reliability critical factors.

Design Considerations for Automated Test Equipment PCBs

Effective ATE PCB design includes:

-

Optimized multilayer stack-up with dedicated signal, power, and ground planes

-

Controlled impedance transmission lines

-

Short signal paths to reduce parasitics

-

Careful via design to minimize signal discontinuities

-

EMI and crosstalk mitigation techniques

Close coordination between PCB designers and test engineers is key to achieving stable and repeatable test performance.

Materials Used in ATE PCBs

Depending on the test frequency and performance requirements, ATE PCBs may use:

-

High-Tg FR-4 for digital test applications

-

Low-loss laminates such as Rogers RO4350B, RO4003C

-

Hybrid stack-ups combining RF materials and FR-4

-

Specialized materials for thermal stability and low dissipation factor

Material selection directly impacts signal quality and test accuracy.

Manufacturing Capabilities for ATE PCBs

Producing high-quality automated test equipment PCBs requires advanced manufacturing processes, including:

-

Fine line and spacing fabrication

-

Multilayer and HDI PCB manufacturing

-

Blind and buried via technology

-

Controlled impedance testing and verification

-

Tight tolerance control for thickness and registration

Precision manufacturing ensures consistent performance across prototype and production volumes.

ATE PCB Assembly Services

ATE PCB assembly often includes:

-

High pin count socket and connector installation

-

Fine-pitch SMT and mixed-technology assembly

-

Reinforcement for mechanically stressed components

-

X-ray inspection and AOI for quality assurance

Reliable assembly is essential for stable electrical performance and long service life.

Applications of Automated Test Equipment PCBs

ATE PCBs are widely used in:

-

Logic IC and processor testing

-

Memory and storage device testing

-

RF and microwave IC testing

-

Automotive and industrial semiconductor testing

-

High-speed communication IC validation

Each application demands precise signal integrity and robust PCB construction.

Prototype and Small Batch ATE PCB Manufacturing

Prototype and small batch ATE PCBs are crucial during early-stage development and test program validation. Fast turnaround times and engineering support enable rapid iteration and optimization of test designs before mass production.

Why Choose a Professional ATE PCB Manufacturer?

An experienced ATE PCB manufacturer provides:

-

Deep expertise in semiconductor test PCB design and fabrication

-

Support for controlled impedance and high-speed requirements

-

Flexible production volumes from prototype to mass production

-

Reliable quality control and test verification

This ensures your automated test equipment operates with maximum accuracy and efficiency.

Conclusion

Automated Test Equipment PCB manufacturing is a key enabler of modern semiconductor testing. With advanced materials, controlled impedance design, and precision manufacturing, ATE PCBs deliver reliable performance for high-speed, high-frequency, and high pin count test applications.

Choosing the right ATE PCB supplier ensures accurate testing, reduced downtime, and long-term reliability in demanding semiconductor test environments.