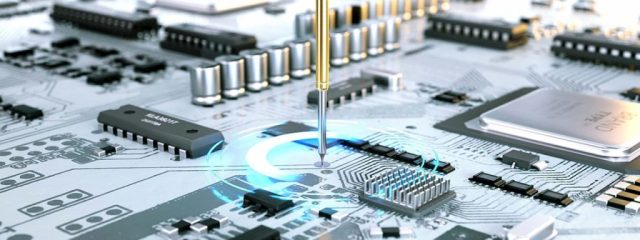

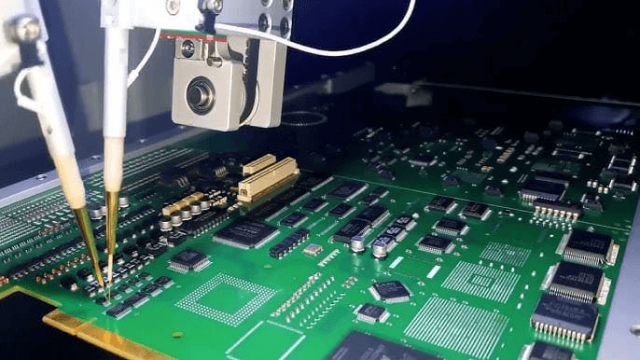

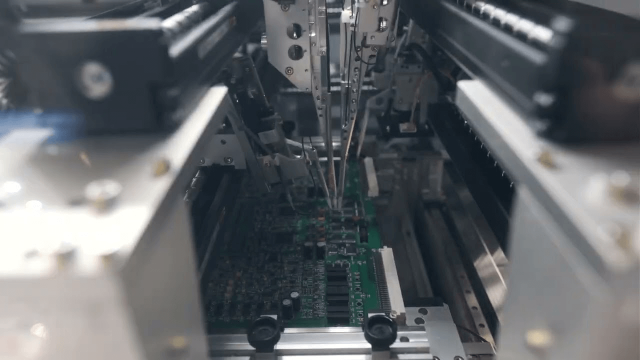

In modern electronics manufacturing and semiconductor testing, accuracy and repeatability are critical. ATE test PCB solutions play a vital role in ensuring that automated test equipment (ATE) delivers consistent, reliable measurement results across high-volume production environments.

A well-designed and precisely manufactured ATE test PCB directly impacts test yield, fault detection accuracy, and overall production efficiency.

What Is an ATE Test PCB?

An ATE test PCB is a specialized printed circuit board used in automated test equipment to interface between the device under test (DUT) and the test system. It routes signals, power, and control lines from the ATE to the DUT with high integrity and minimal distortion.

Unlike standard PCBs, ATE test PCBs are engineered for:

-

High signal integrity

-

Mechanical durability

-

Precise electrical repeatability

-

Long service life under repeated test cycles

Why ATE Test PCB Quality Matters

ATE systems are used to validate ICs, modules, and electronic assemblies at high speed and volume. Any inconsistency in the ATE test PCB can lead to:

-

False test failures

-

Reduced yield

-

Increased retest rates

-

Misleading performance data

High-quality ATE test PCBs ensure accurate signal transmission and stable test conditions across thousands or millions of test cycles.

Key Design Considerations for ATE Test PCBs

Signal Integrity and Controlled Impedance

High-speed digital and RF test signals require:

-

Controlled impedance traces

-

Stable stackup design

-

Proper grounding and shielding

Precise impedance control minimizes reflection and signal distortion.

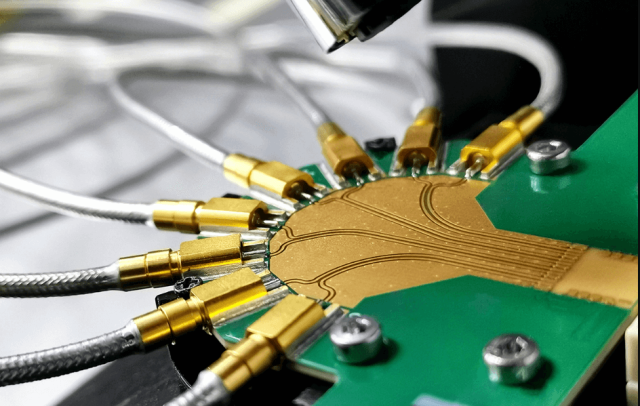

Mechanical Strength and Durability

ATE test PCBs experience frequent insertion, probing, and mechanical stress. Designs must account for:

-

Reinforced connector areas

-

Rigid materials and thickness selection

-

Stable via structures

Durability directly affects test consistency and board lifespan.

Thermal and Power Management

ATE test PCBs often handle varying power levels. Proper copper distribution and thermal design prevent overheating and measurement drift.

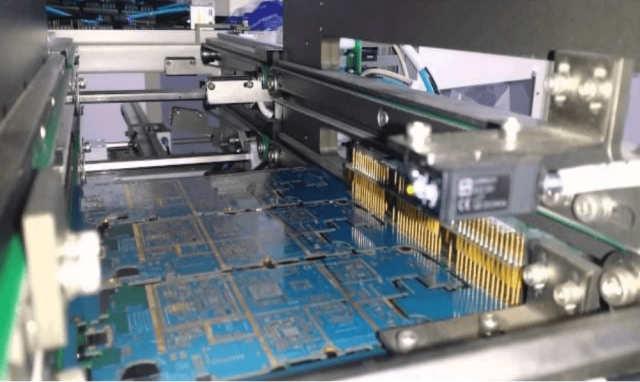

Manufacturing Requirements for ATE Test PCBs

Producing a reliable ATE test PCB requires strict manufacturing control:

-

Tight tolerance drilling and plating

-

High-quality laminate materials

-

Precise layer registration for multilayer boards

-

Electrical testing and inspection

Consistency from board to board is essential for accurate automated testing.

Materials Commonly Used in ATE Test PCBs

Depending on the application, ATE test PCBs may use:

-

High-Tg FR-4 for durability and stability

-

Low-loss laminates for high-speed or RF testing

-

Hybrid stackups for mixed-signal environments

Material selection impacts both electrical performance and mechanical longevity.

Applications of ATE Test PCBs

ATE test PCBs are widely used in:

-

Semiconductor IC testing

-

High-speed digital device validation

-

RF and wireless module testing

-

Automotive electronics testing

-

Consumer electronics production lines

Each application demands precise, repeatable performance.

Prototype to Production for ATE Test PCBs

An experienced ATE test PCB manufacturer supports:

-

Rapid prototype test boards

-

Engineering validation builds

-

Pilot runs for test optimization

-

Stable mass production for volume testing

Smooth transitions ensure consistent test data throughout the product lifecycle.

Choosing the Right ATE Test PCB Manufacturer

When selecting a partner for ATE test PCB production, consider:

-

Experience with test and fixture PCBs

-

Controlled impedance and signal integrity expertise

-

Consistent manufacturing quality

-

Ability to support quick-turn prototypes and volume orders

A reliable supplier improves test accuracy and production efficiency.

Conclusion

An ATE test PCB is a critical component in automated test equipment, directly influencing test accuracy, yield, and reliability. By combining robust design, precise manufacturing, and consistent quality control, high-performance ATE test PCBs enable dependable automated testing across modern electronics manufacturing.

Choosing an experienced ATE test PCB partner ensures your test systems deliver accurate, repeatable results—every cycle, every board.