What Is an ATE PCB Supplier?

An ATE PCB Supplier is a specialized PCB manufacturer that provides printed circuit boards for Automated Test Equipment (ATE) systems. These PCBs are used in test fixtures, load boards, interface boards, and probe cards to ensure accurate, repeatable, and stable electronic testing.

Compared with standard PCBs, ATE PCBs demand higher reliability, tighter tolerances, and longer service life, making the choice of an experienced ATE PCB supplier critical.

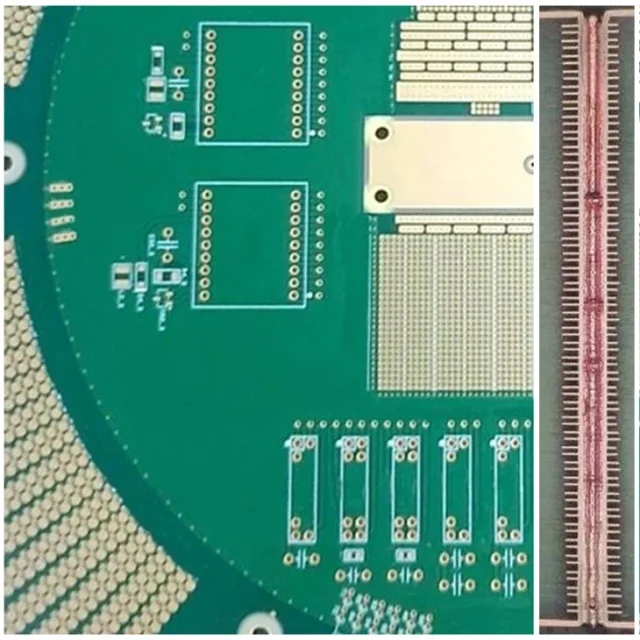

Key Requirements for ATE PCB

An experienced ATE PCB supplier must meet strict technical and quality requirements, including:

-

High mechanical durability

Designed for repeated insertions and long test cycles. -

Stable electrical performance

Ensures consistent signal integrity during high-speed testing. -

Precise impedance control

Supports accurate test measurements. -

Excellent thermal stability

Withstands continuous operation and temperature variations. -

High pin-count and dense routing capability

These requirements differentiate ATE PCB manufacturing from standard PCB production.

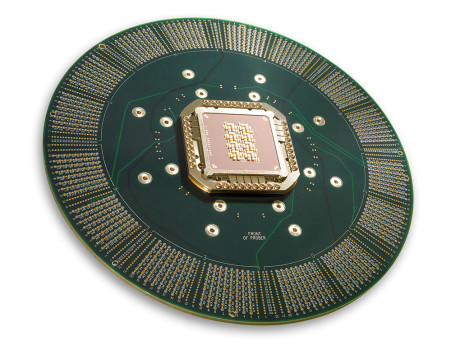

ATE PCB Manufacturing Capabilities

A professional ATE PCB supplier typically offers:

-

Multilayer and high-layer-count PCB fabrication

-

HDI, blind/buried via, and fine-line PCB technology

-

High-frequency and controlled-impedance PCB

-

Hybrid PCB materials and metal-core options

-

Surface finishes suitable for high wear (ENIG, hard gold, ENEPIG)

Advanced capabilities ensure ATE PCBs perform reliably in demanding test environments.

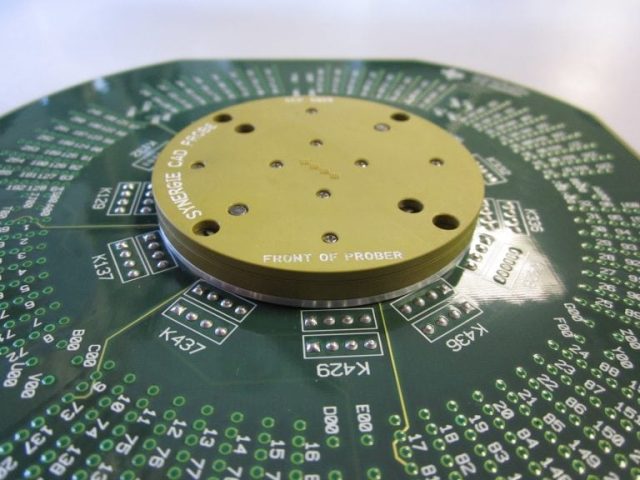

ATE PCB Manufacturing Process

The ATE PCB manufacturing process includes:

-

Engineering review and DFM analysis

Optimizes design for manufacturability and durability. -

Precision fabrication and lamination

Ensures layer alignment and structural integrity. -

Strict quality inspection

AOI, X-ray inspection, and electrical testing. -

Reliability-focused finishing processes

Improves contact durability and lifespan. -

Final testing and packaging

Close quality control is essential for any ATE PCB supplier.

Applications of ATE PCB

ATE PCBs supplied by qualified ATE PCB suppliers are widely used in:

-

Semiconductor testing systems

-

IC and chip functional test platforms

-

Burn-in and stress testing equipment

-

Production-line automated test systems

-

Industrial electronics validation

ATE PCBs play a critical role in ensuring product quality and yield.

How to Choose the Right ATE PCB Supplier

When selecting an ATE PCB supplier, consider:

-

Experience in ATE and test fixture PCBs

-

Manufacturing precision and process control

-

Material and surface finish options

-

Quality certifications and inspection standards

-

Long-term supply stability

A reliable ATE PCB supplier becomes a key partner in maintaining test accuracy and production efficiency.

Conclusion

Choosing the right ATE PCB supplier is essential for building reliable and accurate automated test equipment. With advanced manufacturing capabilities, strict quality control, and deep experience in test PCB applications, a professional ATE PCB supplier ensures consistent performance and long service life.

Partnering with an experienced ATE PCB supplier helps maximize test reliability and minimize system downtime.