Who Is an ATE PCB Supplier?

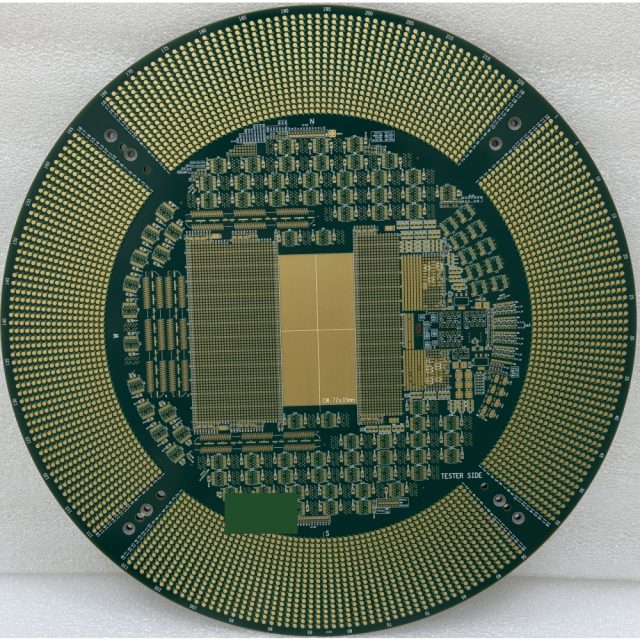

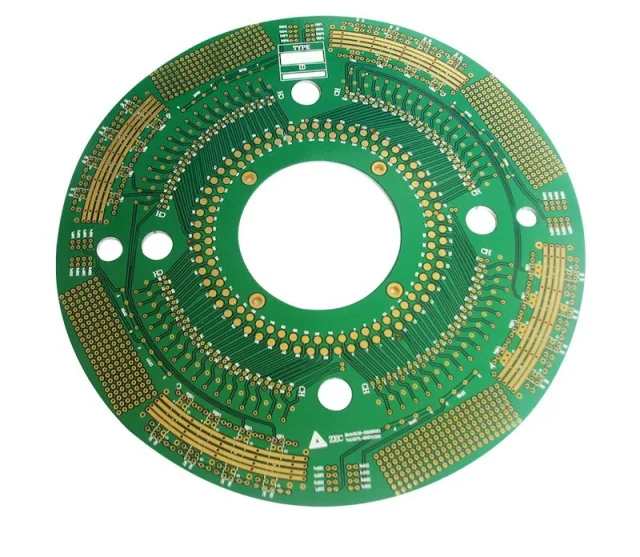

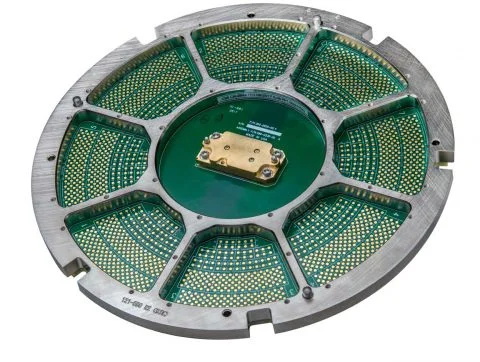

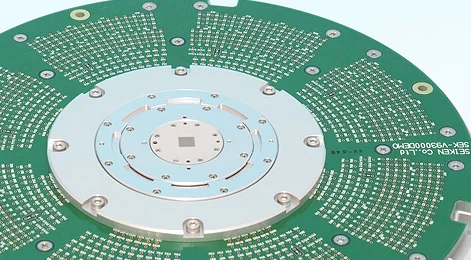

An ATE PCB Supplier is a professional manufacturer and solutions provider of printed circuit boards specifically designed for Automated Test Equipment (ATE) used in semiconductor testing. These suppliers deliver PCBs that serve as the electrical interface between ATE systems and devices under test (DUTs), enabling accurate functional, parametric, and performance testing across high-volume production environments.

ATE PCB suppliers support everything from prototype test boards to fully assembled load boards, high pin count interface boards, RF test boards, and complex controlled impedance solutions.

Why Choose a Specialized ATE PCB Supplier?

Unlike standard PCB vendors, a dedicated ATE PCB supplier brings deep expertise in test-centric designs:

1. Test-Driven PCB Engineering Support

Experienced suppliers work closely with your test engineers to optimize stack-up, impedance control, differential routing, and signal integrity for high-speed test signals.

2. Controlled Impedance and Signal Integrity Expertise

ATE PCBs require precise impedance control, low loss routing, and stable reference planes to ensure repeatable and accurate test results.

3. High Pin Count & Complex Routing Capability

With thousands of I/O channels common in modern test boards, ATE PCB suppliers excel in high pin count layouts, fine pitch routing, and HDI technology.

4. RF and High Frequency Test PCB Experience

Manufacturers with RF and mmWave expertise provide low-loss materials, optimized RF trace designs, and performance verification for high frequency testing.

5. Reliability & Durability for High Volume Testing

ATE PCBs must withstand repeated device insertions, thermal cycling, and long test cycles—suppliers specialize in materials and assembly to achieve long-term reliability.

Key Products & Services from an ATE PCB Supplier

A reputable ATE PCB supplier typically offers:

Load Boards & Interface Boards

High reliability PCBs connecting ATE systems to DUT sockets or probes.

ATE Test PCB Prototypes

Fast-turn prototype boards to support early test program development and validation.

High Pin Count Test Boards

Boards designed for large I/O maps, complex pin routing, and dense connectors.

RF/High Frequency Test PCBs

Test boards using low loss materials for RF, mmWave, and 5G test applications.

Controlled Impedance PCBs

Precise stack-ups and manufacturing to achieve targeted impedance control.

Multilayer & HDI ATE PCBs

Advanced layered structures for power/ground isolation and high routing density.

PCB Assembly & Component Integration

Turnkey assembly services including sockets, connectors, and functional verification.

Technical Capabilities of a Leading ATE PCB Supplier

To support complex semiconductor testing needs, an ATE PCB supplier must typically demonstrate:

-

Controlled Impedance Modeling & Verification

-

High Layer Count PCB Fabrication

-

Fine Pitch, HDI & Microvia Technology

-

Low Loss & High Frequency Material Expertise

-

High TG and High Reliability PCB Manufacturing

-

Thermal and Mechanical Stress Resistance

-

Automated Optical Inspection (AOI), X-Ray & Electrical Testing

These capabilities ensure each test board meets strict performance and reliability standards.

Applications for ATE PCBs

ATE PCBs from a specialized supplier are used in:

-

Wafer Sort & Probe Test Load Boards

-

Final Test Interface Boards

-

IC/Logic Test Platforms

-

Memory & High Speed IC Test Boards

-

RF/5G and mmWave Test Fixtures

-

Automotive & Industrial Semiconductor Test Systems

These boards power the test environments for chips across consumer, automotive, telecom, industrial, and aerospace markets.

Prototype to Volume: ATE PCB Supply Chain Support

Professional ATE PCB suppliers support the entire lifecycle:

-

Rapid Prototype and Design Validation

-

Small Batch Production for Test Trials

-

Scalable Volume Manufacturing

-

Revision Control and Config Management

-

Documentation for Traceability & Quality Systems

This full support enables test engineering teams to accelerate time-to-market and improve test throughput.

Why Partner with the Right ATE PCB Supplier?

Choosing the right ATE PCB supplier delivers:

-

On-Time Delivery for Critical Test Schedules

-

Optimized Electrical Performance & Yield

-

Reduced Debug Cycles & Test Failures

-

Lower Overall Test Implementation Risk

-

Scalable Solutions from Prototype to Production

A trusted supplier becomes an extension of your test engineering capability and helps ensure long-term success in semiconductor validation and production.