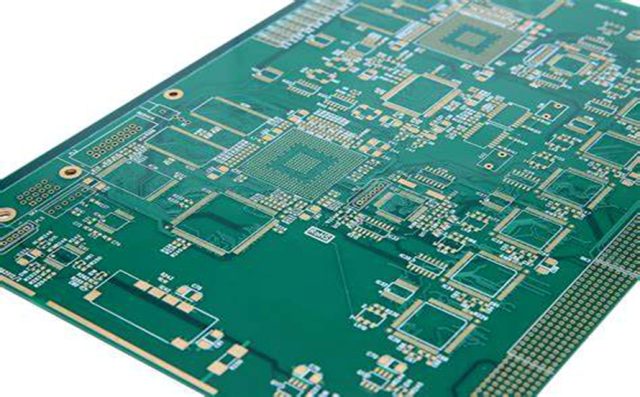

Before an automated test system enters production, its electrical and mechanical behavior must be thoroughly validated. The ATE PCB Prototype serves as the critical platform for early-stage verification, allowing engineers to evaluate signal integrity, power delivery, and interface compatibility under real test conditions.

A well-executed ATE PCB prototype reduces development risk and accelerates time to production.

What Is an ATE PCB Prototype?

An ATE PCB Prototype is an early-stage test board designed to validate test architecture, signal paths, and power requirements for automated test equipment. Unlike production ATE PCBs, prototypes prioritize flexibility, accessibility, and rapid iteration.

Why Prototyping Is Essential in ATE Development

ATE prototyping enables engineers to:

-

Verify signal integrity before volume deployment

-

Identify power and grounding issues early

-

Validate connector, socket, and interface layouts

Early validation prevents costly redesigns later.

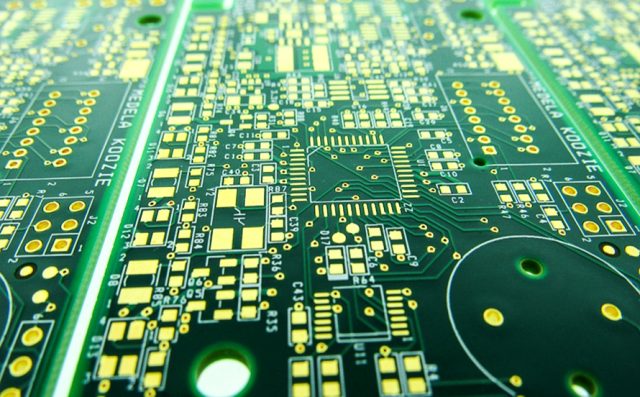

Signal Integrity Validation at the Prototype Stage

High-speed and mixed-signal testing requires clean signal behavior. ATE PCB prototypes focus on:

-

Controlled impedance routing

-

Accessible test points for probing

-

Short and simplified signal paths

These features support accurate measurement and debugging.

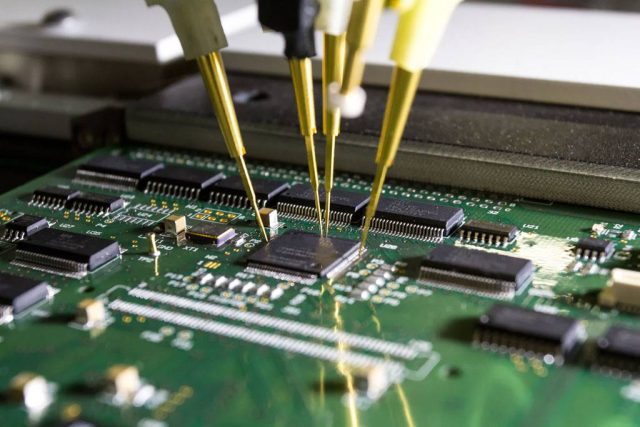

Power Integrity and Debug-Friendly Design

ATE PCB prototypes often include:

-

Separated power domains for evaluation

-

Generous decoupling networks

-

Easy access for current and voltage measurement

This approach simplifies troubleshooting and optimization.

Stackup Flexibility and Design for Iteration

Prototype stackups are designed to:

-

Support multiple signal types

-

Allow design adjustments without major rework

-

Balance performance and cost

Flexible stackups enable faster design cycles.

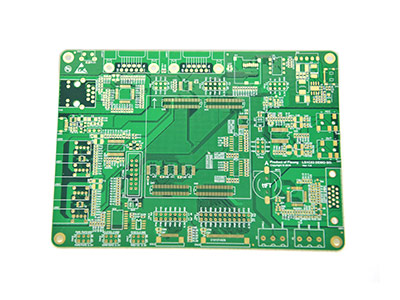

Mechanical and Interface Evaluation

Prototypes validate:

-

Connector and socket positioning

-

Mechanical clearance and alignment

-

Compatibility with ATE fixtures

Mechanical issues are easier to fix at the prototype stage.

Manufacturing Speed and Engineering Support

Rapid turnaround is critical for ATE PCB prototypes. Key considerations include:

-

Fast fabrication and assembly cycles

-

Engineering review and DFM feedback

-

Small-batch production capability

Speed and collaboration accelerate development.

Typical Applications of ATE PCB Prototypes

ATE PCB prototypes are used in:

-

New ATE platform development

-

Semiconductor device characterization

-

Engineering validation and debugging

-

Pre-production test verification

Each application benefits from rapid iteration.

Choosing an ATE PCB Prototype Partner

When selecting an ATE PCB prototype supplier, consider:

-

Experience with test and validation boards

-

Controlled impedance and multilayer capability

-

Fast-turn prototyping and engineering support

-

Ability to scale designs to production

The right partner supports smooth transition to mass production.

Conclusion

The ATE PCB Prototype is a vital step in developing reliable automated test equipment. By enabling fast validation, efficient debugging, and informed design decisions, ATE PCB prototypes help engineers deliver stable and production-ready test systems.

Partnering with an experienced ATE PCB prototype manufacturer ensures rapid progress and reduced development risk.