In semiconductor testing, design validation speed directly impacts development cycles and time-to-market. ATE PCB prototypes provide engineers with a fast and reliable way to verify electrical performance, signal integrity, and mechanical compatibility before committing to volume production.

ATE PCB prototyping is a critical step in developing robust and scalable semiconductor test solutions.

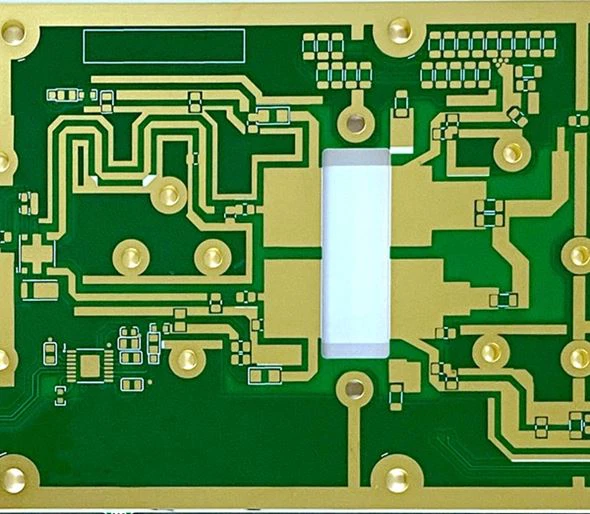

What Is an ATE PCB Prototype?

An ATE PCB prototype is an early-stage test board designed and manufactured to evaluate performance within an automatic test equipment (ATE) environment. These prototypes allow engineers to assess:

-

High-speed signal integrity

-

Controlled impedance accuracy

-

Power delivery stability

-

Mechanical fit and connector alignment

ATE PCB prototypes are typically produced in small quantities for rapid iteration.

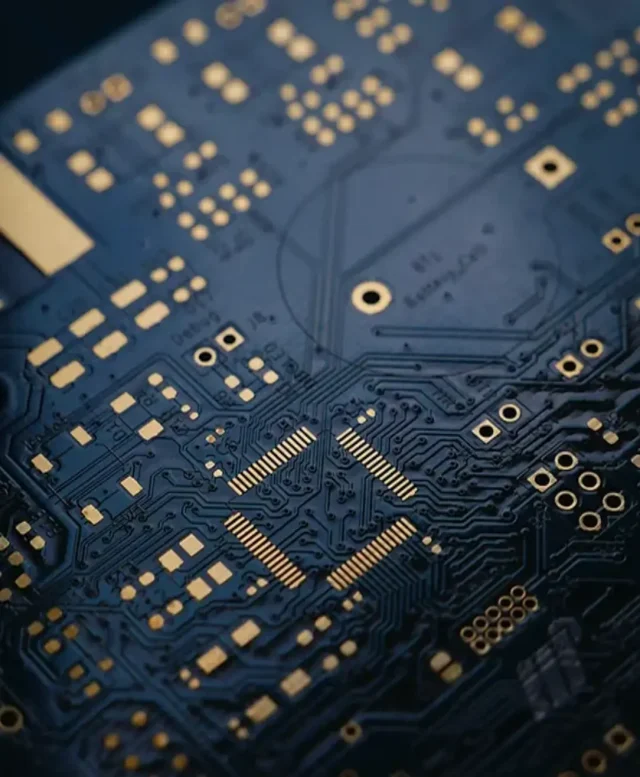

Why ATE PCB Prototypes Are Critical

ATE systems are complex and highly sensitive. ATE PCB prototypes help to:

-

Identify signal integrity issues early

-

Validate stackup and material choices

-

Optimize routing for high pin count devices

-

Reduce risk before mass production

Early testing minimizes costly redesigns in later stages.

Key Design Features of ATE PCB Prototypes

High-quality ATE PCB prototypes include:

-

Multilayer stackups with dedicated power and ground planes

-

Controlled impedance routing for high-speed test channels

-

Fine-pitch routing to support high pin count ICs

-

Compatibility with sockets, probe cards, and load boards

These features ensure realistic test conditions during prototyping.

Fast Turnaround and Engineering Support

Speed is essential in ATE development. ATE PCB prototype services typically offer:

-

Short lead times for fabrication

-

Engineering review and DFM feedback

-

Support for design changes and revisions

Fast iteration enables engineers to refine test solutions efficiently.

Applications of ATE PCB Prototypes

ATE PCB prototypes are widely used in:

-

Semiconductor IC functional and parametric testing

-

Load board and interface board validation

-

High-speed and mixed-signal test development

-

New test platform evaluation

Each application benefits from early performance verification.

Choosing an ATE PCB Prototype Manufacturer

When selecting a manufacturer for ATE PCB prototypes, consider:

-

Experience with semiconductor test and ATE applications

-

Capability for controlled impedance and multilayer PCBs

-

Fast prototyping and small batch manufacturing support

-

Strong quality control and testing processes

A trusted partner helps accelerate development while ensuring accuracy.

Conclusion

ATE PCB prototypes are essential for validating semiconductor test designs and reducing development risk. By enabling rapid iteration, reliable performance testing, and early issue detection, ATE PCB prototyping supports faster and more confident test system development.

Working with an experienced ATE PCB prototype supplier ensures precision, speed, and scalability from prototype to production.