In semiconductor and electronic testing environments, speed and accuracy are critical. ATE PCB prototypes play a key role in validating automated test equipment designs, allowing engineers to quickly evaluate signal integrity, mechanical fit, and electrical performance before full-scale production.

Fast and reliable ATE PCB prototyping reduces development risk and accelerates time-to-market.

What Is an ATE PCB Prototype?

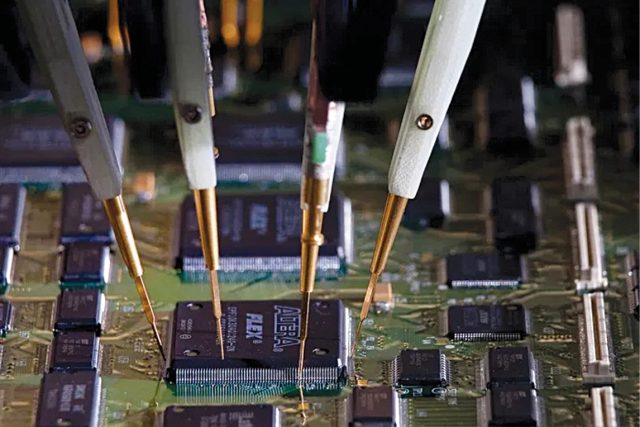

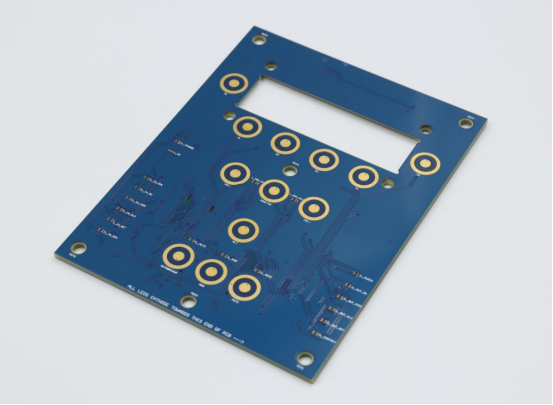

An ATE PCB prototype is an early-stage printed circuit board designed for use in automated test equipment. It serves as the interface between the device under test (DUT) and the ATE system, enabling engineers to verify functionality, performance, and compatibility.

Key objectives include:

-

Early validation of high-speed and high-pin-count designs

-

Functional testing before mass production

-

Rapid engineering iteration and design optimization

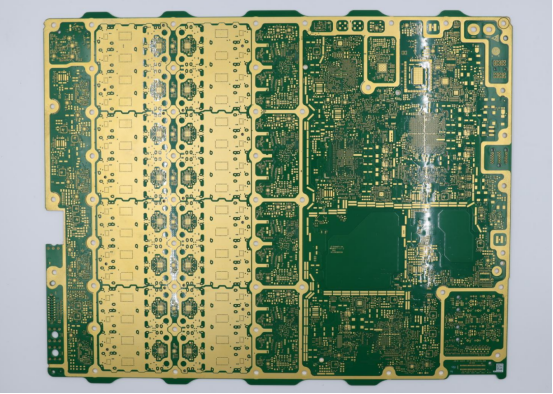

Key Requirements for ATE PCB Prototypes

ATE PCB prototypes must meet strict technical requirements to ensure accurate testing:

-

Controlled Impedance and Signal Integrity

High-speed signals require precise impedance control to avoid reflections and timing errors. -

High Pin Count Support

ATE environments often involve dense interconnects, demanding advanced multilayer routing. -

Mechanical Compatibility

Accurate board dimensions and hole tolerances ensure proper alignment with test fixtures and sockets. -

Fast Turnaround

Rapid fabrication and assembly are essential for shortening development cycles.

Materials and Stackup Options

Common material choices for ATE PCB prototypes include:

-

High-Tg FR-4 for standard prototype testing

-

Low-loss laminates for high-speed or high-frequency validation

-

Hybrid stackups to balance performance, lead time, and cost

Careful stackup planning improves both electrical reliability and manufacturability.

Applications of ATE PCB Prototypes

ATE PCB prototypes are widely used in:

-

Semiconductor IC validation and characterization

-

Load boards and interface boards for ATE systems

-

Wafer test and probe card development

-

High-speed and mixed-signal testing

These prototypes help engineers identify issues early and refine designs efficiently.

Choosing an ATE PCB Prototype Supplier

When selecting a supplier for ATE PCB prototypes, consider:

-

Experience with semiconductor test PCBs and ATE interfaces

-

Capability for controlled impedance and multilayer PCB fabrication

-

Support for fast delivery and small batch production

-

Strong quality control and electrical testing processes

A reliable partner ensures consistent prototype quality and rapid engineering feedback.

Conclusion

ATE PCB prototypes are essential for validating automated test equipment designs and minimizing development risks. By enabling fast iteration, accurate testing, and early problem detection, ATE PCB prototyping accelerates innovation and improves overall testing efficiency.

Working with an experienced ATE PCB prototype manufacturer ensures reliable performance from concept to production-ready designs.