Automated test equipment relies not only on PCB design and fabrication, but also on precise and repeatable assembly. ATE PCB Assembly plays a critical role in ensuring signal integrity, power stability, and mechanical reliability throughout semiconductor testing operations.

High-quality assembly directly impacts test accuracy and system uptime.

What Is ATE PCB Assembly?

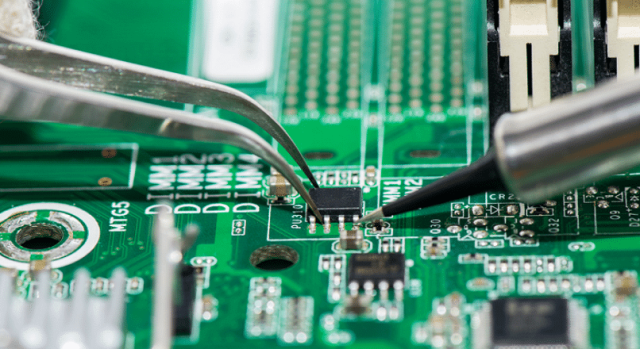

ATE PCB Assembly refers to the process of mounting and soldering electronic components onto ATE PCBs used in semiconductor testing systems. These assemblies must meet strict electrical, mechanical, and reliability requirements to support high-speed and high-density testing.

Assembly Challenges in ATE Applications

ATE PCB assembly faces unique challenges, including:

-

High pin count components and connectors

-

Fine-pitch packages such as BGA and LGA

-

Mixed-signal and high-speed interfaces

Precision assembly processes are essential to overcome these challenges.

Signal Integrity Considerations During Assembly

Improper assembly can degrade signal quality. ATE PCB assembly focuses on:

-

Accurate component placement

-

Controlled solder joint geometry

-

Minimization of parasitic effects

These practices preserve signal integrity across test channels.

Power Integrity and Thermal Management

Stable power delivery depends on correct assembly of:

-

Power components and decoupling capacitors

-

High-current connectors

-

Thermal management elements

Professional assembly ensures consistent electrical performance under load.

Quality Control and Inspection

Reliable ATE PCB assembly includes:

-

Automated optical inspection (AOI)

-

X-ray inspection for hidden joints

-

Functional and continuity testing

These steps reduce the risk of latent defects.

Assembly for Small Batch and Production Volumes

ATE PCB assembly must support:

-

Prototype and small batch builds

-

Engineering validation units

-

Volume production for test platforms

Flexible assembly capability ensures smooth scaling.

Typical Applications of ATE PCB Assembly

ATE PCB assemblies are used in:

-

Semiconductor device testing

-

Load boards and interface boards

-

High-speed digital and mixed-signal test systems

-

Advanced ATE platforms

Each application demands consistent assembly quality.

Choosing an ATE PCB Assembly Partner

When selecting an ATE PCB assembly supplier, consider:

-

Experience with semiconductor test boards

-

Capability for fine-pitch and high-density assembly

-

Robust quality control processes

-

Engineering and NPI support

The right partner ensures reliable performance and fast turnaround.

Conclusion

ATE PCB Assembly is a critical step in delivering reliable automated test equipment. By ensuring precise component placement, stable solder joints, and rigorous quality control, professional ATE PCB assembly supports accurate testing and long-term system reliability.

Partnering with an experienced ATE PCB assembly manufacturer helps ensure consistent results from engineering validation to full production.