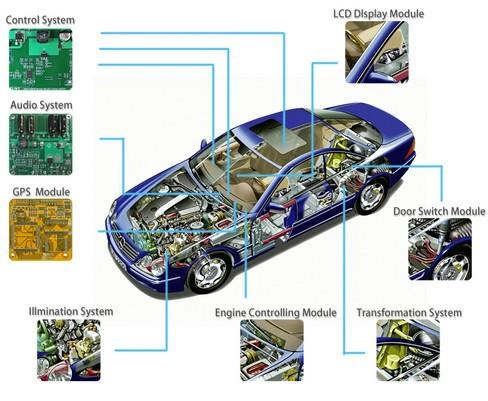

Advanced driver-assistance systems (ADAS) have shifted from premium features to mainstream safety requirements across global automotive platforms. Functions such as adaptive cruise control, automatic emergency braking, lane-keeping assistance, and highway piloting depend on a dense ecosystem of sensors and computing modules. At the center of this ecosystem lies a critical but often overlooked component: the ADAS PCB.

These printed circuit boards serve as the electrical foundation that integrates high-frequency radar, high-resolution cameras, LiDAR units, ultrasonic sensors, domain controllers, and power management systems. In a vehicle traveling under unpredictable environmental and mechanical conditions, the PCB’s durability and signal integrity directly influence how effectively the system can detect obstacles, calculate trajectories, and execute split-second decisions.

Why ADAS PCBs Are Not Standard Automotive Boards

ADAS modules demand higher reliability and performance than typical in-vehicle electronics. Several technical challenges define ADAS PCB design:

Extreme signal speed and bandwidth requirements

77–79 GHz radar modules and multi-gigabit camera links require low-loss, high-frequency laminates with tight impedance control. Micron-level etching accuracy is essential to maintain clean wave propagation under automotive noise and vibration.

Thermal stability in harsh automotive environments

PCBs must withstand temperature cycles from –40°C to +150°C, humidity exposure, engine-bay heat, and long-term oxidation. Failures such as delamination, CAF growth, or copper fatigue cannot be tolerated in safety-critical designs.

Mechanical reliability under vibration and shock

Road shocks, chassis vibration, and long-term fatigue stress demand reinforced board structures, stable dielectric materials, and robust via-interconnect integrity over years of operation.

EMI/EMC immunity for crowded sensor architectures

With radar, cameras, wireless communication, and power electronics operating simultaneously, well-designed stackups and grounding strategies are necessary to prevent interference that may cause misdetection or delayed processing.

Key ADAS Application Segments and Their PCB Requirements

1. 77/79GHz Millimeter-Wave Radar PCB

These PCBs typically use hydrocarbon/ceramic-filled laminates or PTFE-based materials. Ultra-low loss tangent and stable dielectric properties ensure phase consistency and long-range target accuracy.

2. Automotive Camera PCB

High-speed differential pairs, controlled impedance, and low-EMI layouts support MIPI CSI-2 or SerDes video links. For ADAS cameras, fine-pitch BGA assembly and compact multi-layer designs are standard.

3. LiDAR Control PCB

LiDAR demands precision timing, fast switching, and tight thermal management. Mixed-signal layers combine high-power laser drivers with high-speed digital controllers, making PCB insulation and heat spreading vital.

4. Domain Controller / ADAS ECU PCB

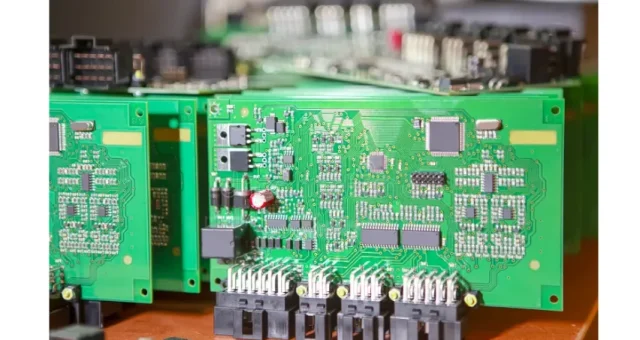

These boards host powerful SoCs, AI accelerators, and memory stacks. High-layer-count HDI boards with buried vias and advanced thermal vias are essential to maintain processing stability.

How KKPCB Supports Automotive-Grade ADAS Manufacturing

KKPCB provides end-to-end PCB fabrication solutions tailored to ADAS electronics, focusing on long-term reliability and functional safety. Our production capabilities include:

• High-frequency material options such as Rogers, Panasonic, Taconic, and Megtron series

• Automotive-grade via protection processes (resin-filled vias, via-in-pad, stacked microvias)

• Controlled impedance from 50Ω to 100Ω with ±5% tolerance

• High-layer-count HDI stackups for ADAS processors and sensor hubs

• 100% AOI, X-ray, and automated flying-probe electrical testing

• IATF 16949-certified workflow for automotive quality assurance

By integrating material science, precision manufacturing, and reliability testing, KKPCB ensures that every ADAS PCB maintains structural integrity, electrical stability, and performance consistency throughout a vehicle’s lifespan.

Driving Toward the Future

As vehicles progress toward higher autonomy levels, the electronic demands on ADAS PCBs will continue to grow. More sensors, faster perception algorithms, and centralized computing architectures will push PCB materials and manufacturing precision to new limits. KKPCB remains committed to supporting automakers and Tier-1 suppliers with dependable, automotive-grade PCB solutions that reinforce the safety and intelligence at the core of modern mobility.