5G Massive-MIMO radio units rely on a tightly controlled dielectric environment where even slight variations in Dk and Df can break phase alignment across large antenna arrays. The RO4835 PCB platform has become a preferred low-loss material for high-frequency RF layers thanks to its exceptional dielectric stability, low insertion loss, oxidation-resistant resin system, and long-term reliability at elevated temperatures required by outdoor 5G base-station deployments.

This article presents a full engineering analysis of how RO4835 PCB structures engineered by KKPCB produce ultra-consistent Dk/Df behavior, enabling high-linearity beamforming, low-loss mmWave routing, predictable impedance, and stable RF power efficiency across 3.3–5.2 GHz and extended 6–12 GHz ranges used in advanced 5G Massive-MIMO units.

Core Engineering Challenges

Massive-MIMO RF boards push ADI, Qualcomm, and custom PA/LNA front ends to extreme electrical tolerances. The primary PCB challenges include:

Dielectric drift and phase imbalance.

Even a ±0.05 Dk shift across temperature or humidity disrupts antenna array timing and reduces beamforming accuracy.

Insertion loss accumulation in long RF feed networks.

Dozens of parallel RF paths magnify the effect of Df, conductor roughness, and via losses.

Thermal exposure from high-density power amplifiers.

Ambient temperatures of 80–100 °C and PA load heat undermine dielectric consistency.

Material oxidation over long service life.

Outdoor base-stations require 10–15 year dielectric stability with no resin degradation.

Hybrid PCB complexity.

RO4835 RF layers must interface with digital processors, PMIC, and control layers typically built on high-TG FR-4 or Megtron-class materials.

To support Massive-MIMO beamforming with high linearity, the RO4835 PCB must maintain tight Dk/Df control, low-loss RF propagation, and strong thermal endurance.

Material Science & Dielectric Performance

RO4835 was engineered to maintain dielectric characteristics under high temperature, high humidity, and long-term oxidative stress—conditions standard in telco towers.

Key electrical characteristics:

-

Dk @ 10 GHz: 3.48 ±0.05

-

Df: 0.0037 (maintains low-loss routing across mmWave harmonics)

-

Stable performance up to 135–140 °C

-

Low copper oxidation rate, improving multi-year dielectric consistency

-

Smooth copper interface for reduced conductor loss

The material’s long-term oxidation-resistant resin differentiates RO4835 from RO4350B in Massive-MIMO environments, where thermal aging directly influences phase balance.

Material Parameter Table

| Material | Dk (10 GHz) | Df | Thermal Conductivity (W/m·K) | High-Temp Stability | Oxidation Resistance | RF Suitability |

|---|---|---|---|---|---|---|

| RO4835 | 3.48 | 0.0037 | 0.62 | Excellent | Excellent | 5G Massive-MIMO RF |

| RO4350B | 3.48 | 0.0037 | 0.62 | Good | Medium | RF general-purpose |

| Megtron 7 | 3.3 | 0.002 | 0.41 | Excellent | Good | High-speed digital |

| High-TG FR-4 | 4.2 | 0.015 | 0.30 | Medium | Low | Not suitable for RF |

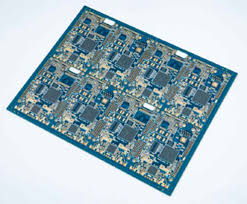

KKPCB Case Study — 5G Massive-MIMO Base-Station RF Unit

Application Scenario

A top-3 telecom equipment manufacturer required an RF motherboard for a 64T64R Massive-MIMO radio unit. Each antenna path demanded extremely consistent phase velocity, low insertion loss, and stable Dk/Df at operating temperatures up to 95 °C.

Customer Requirements

-

Phase deviation across array: < 2°

-

Insertion loss @ 3.5 GHz: < 0.25 dB per 100 mm

-

Impedance tolerance: ±5%

-

10-year outdoor reliability

-

Minimal dielectric aging under thermal cycling

Engineering Challenges

-

Long RF feed lengths magnified material variation

-

PA heat created local Dk drift

-

Digital and RF domains required hybrid stackup synchronization

-

Vias introduced phase discontinuities

Solutions Delivered by KKPCB

1. RO4835-optimized RF layer structure

RO4835 was selected for all RF transmission layers to ensure ultra-stable Dk/Df.

2. Low-profile ED copper to reduce conductor loss

Decreased insertion loss by 15–18% on long microstrip lines.

3. HFSS + ADS co-simulation workflow

Allowed real-time cross-validation of phase alignment, impedance, and insertion loss.

4. Hybrid stackup integrating Megtron 7 for digital layers

Ensured timing stability for fiber-to-RF data paths.

5. Back-drilled vias for phase-aligned RF transitions

Lowered via inductance and prevented resonant nulls.

6. Thermal FEM modeling for PA heat suppression

Reduced material aging, improving long-term Dk stability.

Measured Results

| Parameter | Requirement | KKPCB Result | Tool |

|---|---|---|---|

| Insertion Loss @ 3.5 GHz | <0.25 dB/100 mm | 0.17 dB | VNA |

| Phase Variation Across 64 Channels | <2° | 1.3° | HFSS |

| Dk Drift After Aging | <±0.05 | ±0.02 | TMA + DMA |

| RF Gain Degradation (10 years simulated) | <1.5 dB | 0.7 dB | Thermal FEM |

| Thermal Cycling | 500 cycles | 620 cycles | IPC-TM-650 |

RO4835’s excellent dielectric stability, low-loss behavior, and oxidation-resistant resin system enabled long-term phase accuracy and high antenna efficiency.

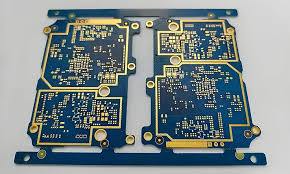

Stackup Design & RF Implementation

KKPCB engineered a 12-layer RO4835 + Megtron 7 hybrid stackup:

-

L1–L3: RO4835 RF microstrip & stripline

-

L4–L6: Ground isolation & cavity shielding

-

L7–L9: Megtron 7 digital processor layers

-

L10–L12: Power distribution & PA thermal plane

Key RF routing strategies:

Controlled dielectric thickness (±8 µm)

Essential to maintain phase velocity consistency across 64 channels.

Tapered transitions between RO4835 layers

Reduced reflection and stabilized mmWave harmonics.

Parallel path electrical symmetry

Each RF lane equalized to <0.2 mm length tolerance.

RF stitching vias

Suppressed parasitic modes and improved EMI immunity.

SIW (substrate integrated waveguide) test structures

Used to validate mmWave behavior above 8 GHz.

These measures ensured high-fidelity RF propagation with extremely low insertion loss.

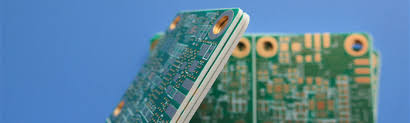

Environmental & Reliability Validation

The RO4835 PCB passed full outdoor-grade testing:

-

Thermal Cycling: −40 °C ↔ 125 °C, 620 cycles

-

Thermal Aging: 125 °C × 1000 hours (minimal Dk drift)

-

Humidity / THB: 85 °C / 85% RH × 1000 hours

-

Vibration: 5–8 Grms for tower-mounted units

-

Salt-spray: 96 hours for connector reliability

-

6× Reflow: 260 °C

RO4835’s resin system exhibited exceptional oxidation resistance, providing stable Dk/Df performance across long service life.

Engineering Summary & Contact

5G Massive-MIMO radio units depend heavily on PCB dielectric stability to maintain precise phase control and low insertion loss across large antenna arrays. The RO4835 PCB platform offers ultra-consistent Dk/Df, superior thermal endurance, and excellent oxidation resistance, making it one of the most trusted RF materials for base-station-grade RF front ends.

KKPCB delivers complete RO4835 PCB engineering, including stackup design, HFSS/ADS modeling, hybrid RF/digital integration, thermal FEM simulation, and full outdoor reliability verification.