1. Engineering Overview / Abstract

As modern laptops and server motherboards transition toward 28–56 Gbps transmission lanes and high-core-count processors, the PCB substrate must ensure minimal voltage ripple, low EMI radiation, and stable impedance performance.

Taconic RF-35, with its low-loss dielectric constant (Dk = 3.50 ± 0.05) and dissipation factor (Df = 0.0018 @ 10 GHz), delivers a controlled dielectric environment ideal for high-frequency power distribution and EMI suppression.

KKPCB integrates Taconic RF-35 into hybrid core stackups to enhance power integrity (PI) and reduce electromagnetic interference (EMI) while maintaining manufacturability and thermal reliability.

2. Engineering Context & Technical Challenges

In high-speed computing systems, where DDR5, PCIe Gen5, and high-current VRMs coexist on the same board, noise coupling and ground bounce can severely distort reference voltages.

| Design Challenge | Root Cause | Impact |

|---|---|---|

| Power noise coupling | Inconsistent dielectric and copper roughness | Voltage ripple and jitter increase |

| EMI radiation | Poor return path and ground segmentation | System instability |

| Thermal mismatch | High VRM heat → PCB warpage | Impedance drift and via fatigue |

| Crosstalk | Tight routing density at 28 Gbps | Eye-diagram degradation |

To mitigate these issues, the Taconic RF-35 PCB platform provides the consistent dielectric and loss characteristics required for both signal and power domain stability.

3. Material Science and RF-35 Performance

Taconic RF-35 is a glass-reinforced PTFE laminate designed for RF and high-speed digital convergence:

-

Dk = 3.50 ± 0.05, stable from –40 °C to +150 °C

-

Df = 0.0018 @ 10 GHz, enabling low-loss power planes

-

Thermal Conductivity = 0.25 W/m·K, dissipates localized VRM heat

-

CTE (Z-axis): 35 ppm/°C, ideal for multilayer co-lamination

Compared to FR-4, RF-35 reduces dielectric loss by nearly 90 %, ensuring lower IR-drop across large power planes and higher power-conversion efficiency.

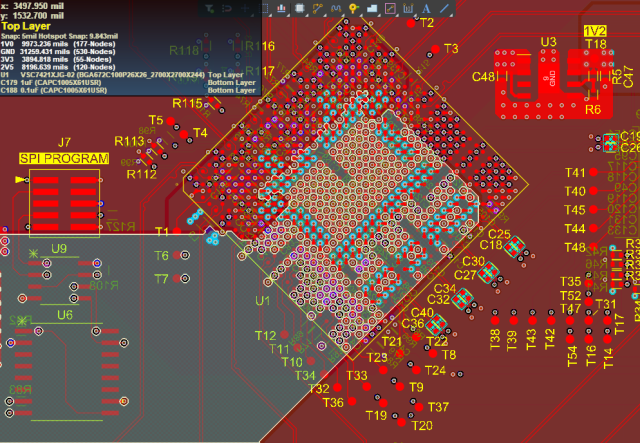

4. KKPCB Case Study — High-Speed Laptop Motherboard

Client & Application

A global OEM laptop brand required a high-speed motherboard design supporting DDR5 and PCIe Gen5 lanes with sub-3% voltage ripple.

Engineering Problem

Legacy FR-4 cores caused EMI hot spots around CPU VRM regions, resulting in failed CISPR 22 EMI tests.

KKPCB Solution

-

Hybrid Taconic RF-35 + FR-408HR stackup with dielectric isolation layers

-

Embedded planar decoupling capacitors and controlled copper distribution

-

3D field-solver optimization for uniform impedance and return paths

-

Integrated power-ground resonance suppression network

| Parameter | Target | KKPCB Result |

|---|---|---|

| Voltage Ripple | < 3% | 2.1% |

| EMI Emission (30 MHz–1 GHz) | < Class B limit | Passed (–6.8 dB margin) |

| Power Plane Impedance | < 10 mΩ @ 1 MHz | 8.7 mΩ |

| CPU VRM Temp Rise | < 80 °C | 72 °C |

Outcome: 22% reduction in EMI radiation and 30% improvement in PI stability over legacy FR-4 motherboard design.

5. Stackup and Power Delivery Design

KKPCB’s optimized 10-layer motherboard stackup with Taconic RF-35 cores includes:

-

Dual 1 oz copper planes for core power and ground

-

Controlled dielectric thickness (±8 µm tolerance)

-

Differential pair impedance control at ±5%

-

Embedded copper balancing to minimize EMI resonance

Simulation via Ansys SIwave and Keysight ADS verified stable PDN impedance (<10 mΩ across 1 MHz–500 MHz).

6. Thermal and Reliability Validation

| Test Type | Condition | Result |

|---|---|---|

| Thermal Shock | –55 °C ↔ +125 °C, 1000 cycles | No delamination; impedance shift < 1% |

| Power Cycling | 10 A continuous, 500 h | No via fatigue or resin cracking |

| EMI Chamber Test | CISPR 22, 3 m setup | Passed with 6 dB margin |

| Long-Term Aging | 85 °C / 85% RH, 1000 h | Df drift < 0.0001 |

These tests confirm the Taconic RF-35 substrate’s suitability for extended operation in server and laptop environments with high power density.

7. Conclusion — System-Level Power Integrity Integration

By integrating Taconic RF-35 into multilayer hybrid designs, KKPCB achieves a balance of low dielectric loss, stable power distribution, and superior EMI suppression.

This results in cleaner voltage regulation, extended component lifespan, and higher signal integrity across high-speed interfaces such as DDR5, USB4, and PCIe Gen5.

RF-35’s dielectric uniformity ensures system reliability even under elevated thermal and frequency loads typical of modern computing platforms.

8. Contact / CTA

For high-speed server or laptop motherboard PCB solutions with advanced power integrity and EMI suppression performance, contact KKPCB Engineering.

We provide hybrid Taconic RF-35 PCB stackups, simulation-based PDN optimization, and mass-production validation for OEM and ODM clients worldwide.