Ensuring Consistent RF Performance Through KKPCB’s Validation Process

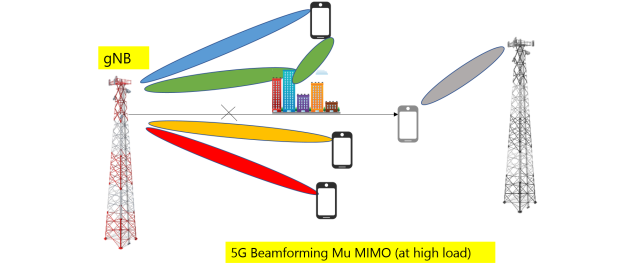

In high-frequency applications—from 77 GHz automotive radar to 28 GHz 5G antenna arrays—the long-term stability and reliability of the PCB material determine system integrity more than any single design parameter.

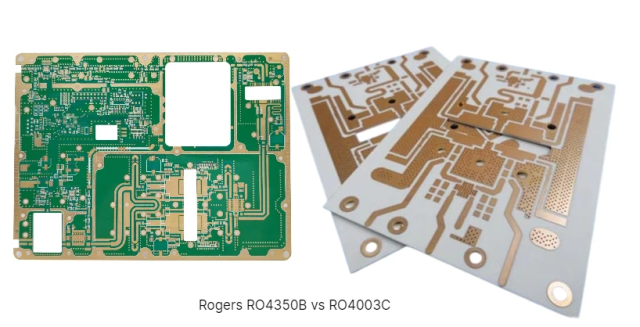

Among numerous high-frequency laminates, Rogers RO4350B PCB stands out for its balance of low dielectric loss, tight Dk tolerance, and compatibility with standard FR-4 manufacturing.

However, to truly realize its performance potential, RF testing and reliability validation must be integrated into both engineering design and mass production stages.

This article explores how KKPCB ensures repeatable RF consistency through systematic testing, process validation, and long-term reliability evaluation for RO4350B-based modules.

1. Why RF Testing Is Critical for RO4350B PCBs

At millimeter-wave frequencies, even minor dielectric or geometric variations can cause phase errors, reflection spikes, or pattern distortion.

In a 24–77 GHz operating window, a 0.05 mm via misalignment or ±0.02 Dk drift can reduce antenna gain by 1–2 dB.

That’s why every RO4350B PCB must undergo RF performance validation beyond standard electrical continuity checks.

Common Failure Modes in Untested Boards

-

Phase deviation between antenna channels

-

Insertion loss instability after reflow or aging

-

Micro-void reflections near plated through-holes

-

CTE-induced impedance drift under thermal stress

KKPCB’s engineering team integrates RF validation into every production stage to eliminate these potential deviations before shipment.

2. KKPCB’s RF Testing Framework

KKPCB’s validation lab operates from 1 GHz up to 110 GHz, combining vector network analyzers (VNAs), TDR impedance testers, and thermal cycling chambers to ensure each batch meets strict RF and mechanical criteria.

| Test Category | Equipment / Method | Purpose |

|---|---|---|

| S-Parameter Measurement | Agilent PNA-X / Keysight VNA | Verify insertion loss (S21), return loss (S11), phase stability |

| TDR Impedance Test | Polar CITS / Z-metrix | Check microstrip & stripline impedance uniformity |

| Thermal Cycling Test | -40°C ~ +125°C / 1000 cycles | Evaluate dielectric stability and via integrity |

| Humidity & Aging Test | 85°C / 85% RH for 96 hrs | Assess resin-adhesion and moisture absorption |

| Cross-Section Analysis | Optical / SEM Inspection | Detect voids, delamination, or resin starvation |

Each batch of RO4350B PCB undergoes traceable data validation, forming the foundation of KKPCB’s RF process control and customer qualification reporting.

3. Case Study: Reliability Qualification of 28 GHz 5G Antenna Module

A global telecom OEM collaborated with KKPCB to validate its RO4350B 6-layer 5G antenna array for outdoor small-cell deployment.

Challenges

-

Impedance variation between RF and control layers

-

Moisture-related Dk drift after environmental exposure

-

Aging-induced increase in insertion loss

KKPCB Testing Process

-

Pre-lamination moisture bake to stabilize dielectric response

-

Batch-level impedance sampling via in-line TDR

-

VNA verification at 28 GHz for insertion loss and phase consistency

-

85/85 environmental stress test for 96 hours

| Metric | Before Optimization | After KKPCB Validation |

|---|---|---|

| Impedance Uniformity | ±10 % | ±3 % |

| Insertion Loss Variation | 0.32 dB | 0.15 dB |

| Dk Drift (Post 85/85) | 0.04 | 0.01 |

| Module Yield | 89 % | 98 % |

Engineering Insight:

During reliability testing, most Dk drift originated from inconsistent prepreg moisture absorption.

By introducing a controlled pre-bake and vacuum lamination step, KKPCB achieved stable dielectric response across all production lots.

4. Long-Term Reliability Evaluation for Automotive and 5G Applications

KKPCB’s RO4350B validation extends beyond standard RF parameters, focusing on lifetime reliability for automotive and telecom environments.

Key Evaluation Metrics

-

Thermal Shock (−40°C ~ +125°C) → via barrel reliability

-

HAST (Highly Accelerated Stress Test) → moisture absorption resistance

-

CTE Analysis → layer interface stability

-

Cross-Hatch Adhesion Test → resin-to-copper bonding strength

-

Phase Drift Monitoring → under cyclic temperature load

All data are summarized in reliability qualification reports (AEC-Q / IPC-TM-650), available for OEM engineering validation or PPAP documentation.

5. KKPCB’s Advantage in RF Reliability Manufacturing

Unlike conventional PCB fabricators, KKPCB integrates testing-driven manufacturing into every production run.

This ensures every RO4350B board not only meets design impedance targets but also performs reliably under real-world thermal and environmental stress.

-

VNA validation up to 110 GHz

-

±5 µm etching tolerance for RF trace precision

-

Automated impedance verification & SPC data control

-

IATF 16949-certified automotive PCB production line

-

On-site RF & reliability lab for 24-hour feedback cycles

Conclusion – From RF Design to Proven Field Reliability

In high-frequency PCB design, testing defines trust.

Rogers RO4350B offers a stable electrical foundation, but only with comprehensive validation and process discipline can it achieve mass-production reliability.

With KKPCB’s RF testing and reliability framework, OEMs can confidently deploy their 5G, radar, or satellite modules—knowing that every PCB has been electrically verified, thermally validated, and field-tested for long-term stability.

Planning your next RF project?

Our engineering team can help you:

-

Validate impedance and insertion loss before mass production

-

Develop AEC-Q / PPAP reliability reports for automotive systems

-

Accelerate RF qualification for 5G and mmWave products

Contact KKPCB Engineering Support to schedule an RF reliability consultation or testing service.