Bergquist Thermal Clad: High-Performance PCB Laminates for Thermal Management and High-Power Applications

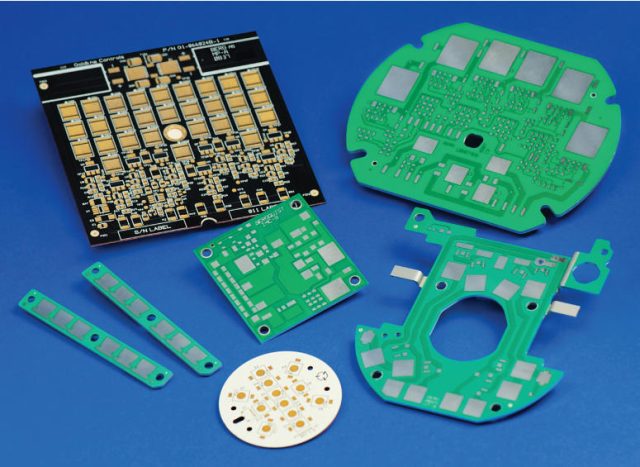

Bergquist Thermal Clad is a premium high-performance PCB laminate designed for applications requiring excellent thermal conductivity, mechanical stability, and reliable electrical performance under extreme operating conditions. Engineered to manage heat efficiently, it is widely used in power electronics, LED lighting, automotive, industrial electronics, aerospace, and RF/microwave applications, where thermal management and electrical reliability are critical.

By combining thermally conductive cores with robust copper cladding and reinforced substrates, Thermal Clad offers a unique solution for modern high-power and high-frequency electronics, ensuring both performance and longevity.

Key Features of Bergquist Thermal Clad

1. Material Composition

-

Thermally Conductive Core: Optimized to remove heat from active electronic components and prevent hot spots.

-

Copper Cladding: High-quality copper layers provide reliable electrical conduction and excellent solderability.

-

Reinforced Substrate: Enhances dimensional stability, mechanical strength, and resistance to thermal stress.

-

Composite Structure: The combination of thermally conductive core, copper, and reinforced substrate ensures both mechanical integrity and superior thermal performance.

2. Thermal Properties

-

High Thermal Conductivity: Efficiently transfers heat away from components, improving reliability and lifespan.

-

Low Thermal Resistance: Maintains low junction-to-board temperature differences for high-power applications.

-

Thermal Stability: Resists performance degradation even under prolonged high-temperature operation.

-

Low Coefficient of Thermal Expansion (CTE): Minimizes stress on solder joints and components during thermal cycling.

3. Electrical Properties

-

Controlled Dielectric Constant (Dk): Ensures stable signal transmission for high-frequency and RF circuits.

-

Low Dissipation Factor (Df): Reduces energy loss and maintains signal integrity.

-

High Insulation Resistance: Ensures electrical isolation even under high-temperature conditions.

-

Consistent Performance Across Frequency: Ideal for RF, microwave, and high-speed digital circuits.

4. Mechanical Properties

-

High Strength & Durability: Resists warping, cracking, and delamination under mechanical and thermal stress.

-

Moisture Resistance: Low moisture absorption maintains consistent performance in humid or challenging environments.

-

Dimensional Stability: Supports precise drilling, plating, and microvia formation in multilayer PCB fabrication.

Applications

1. Power Electronics

Thermal Clad laminates are ideal for power amplifiers, inverters, converters, and power modules where heat dissipation is critical. High thermal conductivity reduces junction temperature, improving efficiency and component life.

2. LED Lighting

High-power LED boards require effective thermal management to prevent overheating. Thermal Clad enables uniform heat distribution, prolonging LED lifetime and ensuring consistent light output.

3. Automotive Electronics

Used in engine control units (ECUs), battery management systems, motor controllers, and high-power automotive modules, Thermal Clad withstands high temperatures and harsh automotive environments.

4. Industrial Electronics

Ideal for high-temperature sensors, motor drives, industrial control systems, and robotics, providing reliability under continuous thermal stress.

5. RF & High-Frequency Applications

Maintains signal integrity in RF and microwave circuits where high thermal loads could otherwise degrade performance. Supports high-frequency, low-loss signal transmission.

Fabrication and Handling Guidelines

1. Material Handling

-

Store in a cool, dry environment to prevent moisture absorption and contamination.

-

Clean laminate surfaces thoroughly before processing to ensure optimal adhesion and etching results.

2. Drilling & Machining

-

Use sharp, high-quality tools designed for thermally conductive and reinforced laminates.

-

Employ proper cooling techniques to prevent localized heating during drilling.

3. Etching & Circuit Formation

-

Compatible with standard PCB fabrication techniques, including photoresist etching, laser processing, and fine-line patterning.

-

Supports multilayer stacking with controlled thickness and minimal warping.

4. Soldering & Assembly

-

Withstands high soldering temperatures (including lead-free soldering) without degradation.

-

Supports heat sinking and thermal management strategies for high-power components.

Advantages of Bergquist Thermal Clad

-

Superior Thermal Management: Efficiently transfers heat from high-power components, reducing thermal stress and improving reliability.

-

High Reliability: Maintains electrical and mechanical integrity under thermal, mechanical, and environmental stress.

-

Low Signal Loss: Preserves performance for RF, microwave, and high-speed digital circuits.

-

Versatile Applications: Supports aerospace, automotive, industrial electronics, LED lighting, and power electronics.

-

Manufacturing Flexibility: Compatible with standard PCB fabrication processes, including multilayer boards, microvias, and fine-line etching.

Technical Summary (Example Values)

| Property | Value |

|---|---|

| Dielectric Constant (Dk) | Controlled for high-frequency performance |

| Dissipation Factor (Df) | Low, optimized for minimal signal loss |

| Thermal Conductivity | High, application-specific |

| Coefficient of Thermal Expansion (CTE) | Low for mechanical stability |

| Moisture Absorption | Minimal |

| Operating Temperature | High, suitable for extreme environments |

For detailed processing guidelines, application examples, and performance specifications, consult the Bergquist Thermal Clad datasheet.