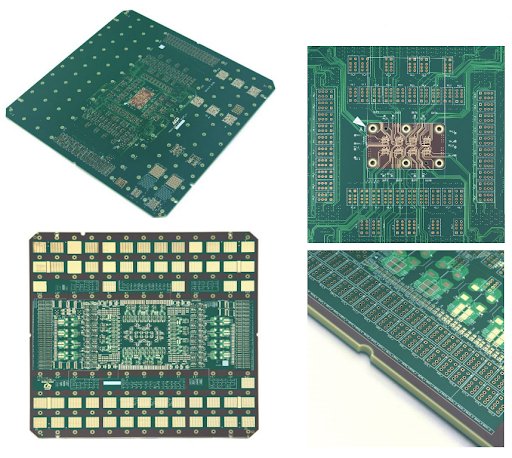

An ATE PCB Prototype is a critical early-stage test board used in automated test equipment (ATE) systems to validate electrical performance, signal integrity, and mechanical compatibility before volume production. In semiconductor testing, a reliable ATE PCB prototype helps reduce development risk, shorten validation cycles, and improve overall test accuracy.

As test speeds continue to increase, ATE PCB prototypes must support high data rates, tight impedance control, and complex multilayer structures.

What Is an ATE PCB Prototype?

An ATE PCB Prototype is a preliminary version of an ATE test board designed to interface between the test system and the device under test (DUT). It is used during engineering validation, debug, and qualification phases to verify routing, impedance, timing, and connectivity.

ATE PCB prototypes are commonly used for:

-

Wafer sort testing

-

Final IC testing

-

Engineering characterization

-

System-level validation

Key Requirements of ATE PCB Prototypes

Controlled Impedance Design

Accurate impedance control is essential for high speed digital and RF test signals. ATE PCB prototypes are fabricated with precise trace geometry and verified impedance testing.

High Speed Signal Integrity

Fast edge rates and multi-gigabit data paths require careful stack-up design, reference plane control, and minimized signal loss.

High Layer Count and Density

ATE PCB prototypes often use multilayer constructions to support dense routing, power distribution, and ground isolation.

Mechanical Accuracy

Connector alignment, socket mounting, and planarity are critical to ensure proper mating with ATE systems and DUT interfaces.

Materials Used in ATE PCB Prototypes

Depending on test frequency and performance requirements, ATE PCB prototypes may use:

-

High-performance FR-4

-

Rogers RO4350B, RO4835, RO4003

-

Megtron 6 / Megtron 7

-

Taconic high frequency laminates

-

Hybrid material stack-ups

Material selection directly affects insertion loss, impedance stability, and thermal reliability.

ATE PCB Prototype Manufacturing Capabilities

Professional ATE PCB prototype manufacturing includes:

-

Tight tolerance multilayer fabrication

-

Controlled impedance modeling and measurement

-

Blind via and buried via processes

-

HDI routing for fine-pitch interfaces

-

Back drilling for improved signal integrity

These processes ensure the prototype accurately represents final production performance.

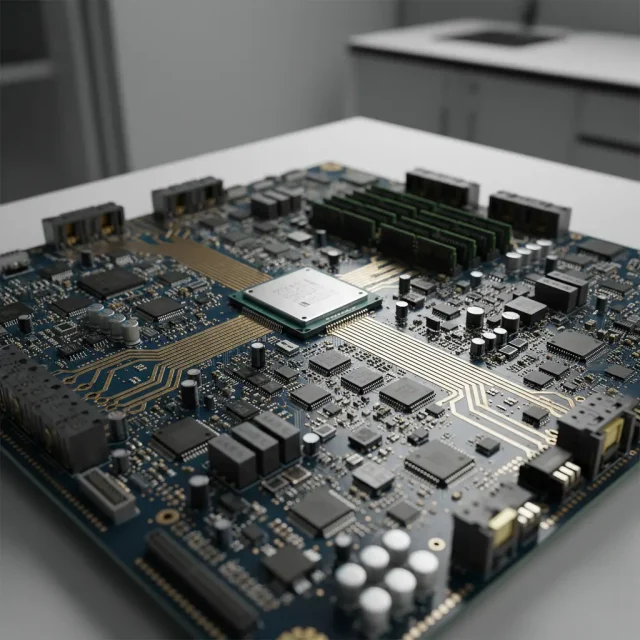

ATE PCB Prototype Assembly

Assembly quality is critical for ATE PCB prototypes, especially when validating electrical performance. Typical assembly services include:

-

High pin count connector and socket installation

-

Fine-pitch SMT and mixed technology assembly

-

X-ray inspection and AOI

-

Functional and continuity testing

Proper assembly ensures the prototype provides reliable and repeatable test results.

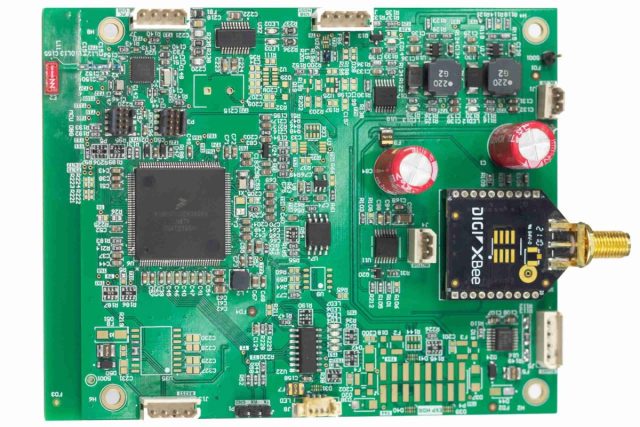

Applications of ATE PCB Prototypes

ATE PCB prototypes are widely used in:

-

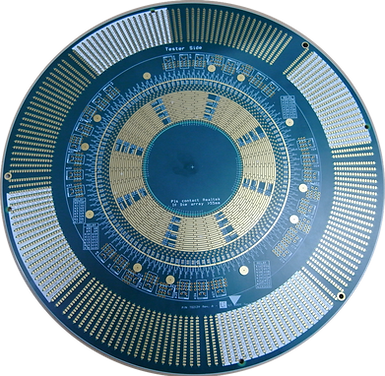

Semiconductor ATE load boards

-

Probe card interface boards

-

High speed logic and memory testing

-

RF and mixed-signal IC evaluation

-

Automotive and industrial device testing

In these applications, early prototype accuracy directly impacts yield and test program success.

From Prototype to Production

ATE PCB prototypes serve as the foundation for volume manufacturing. Once the prototype is validated, the design can transition smoothly into small batch or mass production with minimal risk.

Working with an experienced ATE PCB prototype supplier ensures consistency, fast iteration, and long-term manufacturing stability.

Conclusion

An ATE PCB Prototype plays a vital role in modern semiconductor testing by enabling early validation of signal integrity, impedance control, and mechanical reliability. With advanced materials, precision fabrication, and reliable assembly, ATE PCB prototypes help accelerate product development and improve test confidence.