A High Frequency Test PCB is a critical component in RF, microwave, and high-speed electronic testing environments. As signal frequencies and data rates continue to increase in applications such as 5G communication, mmWave modules, radar systems, and high-speed semiconductor devices, conventional test PCBs can no longer meet accuracy and stability requirements.

High frequency test PCBs are specifically designed to minimize signal loss, maintain precise impedance control, and deliver repeatable performance under demanding test conditions.

What Is a High Frequency Test PCB?

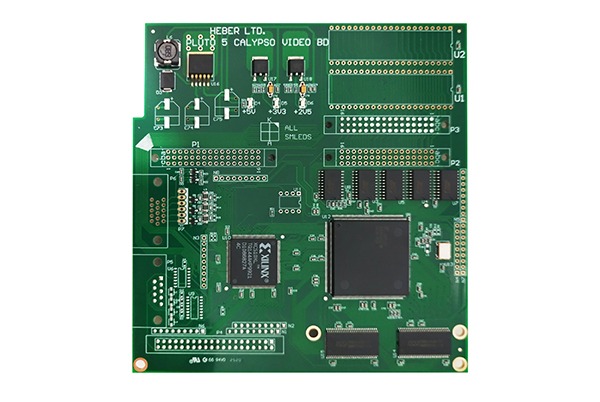

A High Frequency Test PCB is a specialized printed circuit board used to test electronic devices operating at high frequencies. These PCBs serve as the interface between the device under test (DUT) and test equipment, enabling accurate signal injection, measurement, and validation.

Compared to standard test PCBs, high frequency test PCBs require tighter electrical tolerances, low-loss materials, and optimized RF layouts to ensure reliable test results.

Key Requirements for High Frequency Test PCBs

Low Signal Loss

At high frequencies, dielectric and conductor losses significantly affect signal accuracy. High frequency test PCBs use low Df materials to reduce attenuation and distortion.

Precise Controlled Impedance

Accurate impedance control is essential to minimize reflection and phase error. Stack-up design, trace geometry, and dielectric thickness must be tightly controlled.

Excellent Signal Integrity

Short signal paths, optimized grounding, and reduced via discontinuities help preserve signal integrity during testing.

Mechanical and Thermal Stability

High frequency test PCBs must withstand repeated test cycles, connector mating, and temperature variation without performance degradation.

Materials Used in High Frequency Test PCB Manufacturing

Material selection plays a key role in high frequency test PCB performance:

-

Rogers RO4003C, RO4350B, RO4835

-

RT/duroid 5880 and 6010

-

Taconic RF-35, TLY-5

-

Low-loss hybrid stack-ups with high-Tg FR-4

An experienced high frequency test PCB manufacturer helps select materials based on test frequency, durability, and cost considerations.

Manufacturing Capabilities for High Frequency Test PCBs

Producing reliable high frequency test PCBs requires advanced fabrication technology:

-

Controlled impedance PCB manufacturing

-

Precision multilayer and hybrid lamination

-

Fine line and space etching for RF accuracy

-

Laser drilling for microvias and RF vias

-

RF-optimized surface finishes such as ENIG or immersion silver

-

TDR and impedance verification

Strict process control ensures consistent test performance.

Design Challenges and Engineering Support

Designing a high frequency test PCB involves several challenges:

-

High-speed signal routing and isolation

-

Minimizing via stubs and discontinuities

-

Connector, probe, and socket integration

-

EMI and grounding optimization

-

Repeatability across multiple test fixtures

Professional PCB suppliers provide DFM, signal integrity review, and impedance analysis to improve test accuracy and reliability.

Applications of High Frequency Test PCBs

High frequency test PCBs are widely used in:

-

RF and microwave module testing

-

5G and mmWave device validation

-

Semiconductor wafer and package testing

-

Radar and automotive electronics testing

-

High-speed digital and SerDes testing

-

ATE and test interface systems

In these applications, accurate and repeatable testing is essential for product validation.

From Prototype to Production

High frequency test PCB projects typically begin with prototype builds to validate signal integrity, impedance accuracy, and mechanical durability. Once approved, the same design and manufacturing processes are scaled to small-batch or volume production, ensuring consistent performance across all test systems.

Conclusion

A High Frequency Test PCB is a mission-critical component for validating RF, microwave, and high-speed electronic devices. By combining low-loss materials, precise impedance control, and advanced manufacturing processes, professional PCB suppliers deliver test PCBs that ensure accurate, repeatable, and reliable measurement results.

As test frequencies and system complexity continue to increase, partnering with an experienced high frequency test PCB manufacturer is essential for achieving long-term testing success.