What Is a High TG PCB?

A High TG PCB is a printed circuit board manufactured using materials with a high glass transition temperature (Tg). The Tg value indicates the temperature at which the PCB substrate transitions from a rigid state to a softer, rubber-like state.

Compared to standard FR-4, High Tg PCBs maintain mechanical strength, electrical stability, and dimensional accuracy at higher operating temperatures.

Why High TG Matters in PCB Design

Using a High TG PCB provides critical benefits:

-

Improved thermal stability

-

Reduced risk of delamination

-

Better resistance to thermal cycling

-

Higher reliability during soldering and reflow

-

Stable electrical performance at elevated temperatures

These advantages are essential for high-reliability electronics.

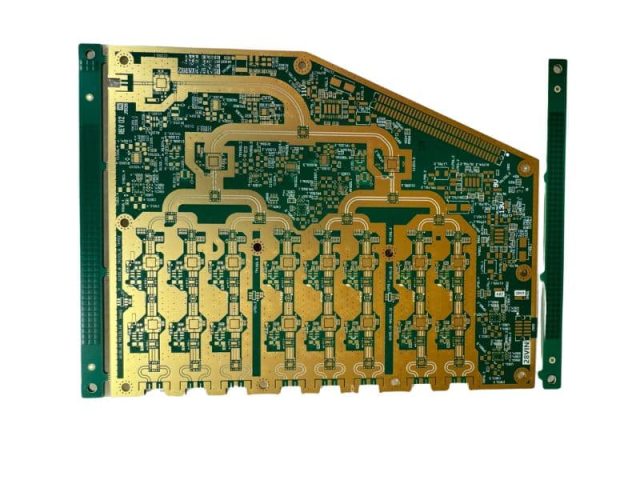

High TG PCB Material Options

Common materials used for High TG PCB fabrication include:

-

High Tg FR-4 (Tg ≥ 170°C)

-

Enhanced FR-4 with low CTE

-

High-speed and low-loss materials with high Tg

-

Hybrid PCB materials for mixed-signal designs

-

Ceramic or metal-core PCBs for extreme thermal environments

Material selection depends on thermal, electrical, and mechanical requirements.

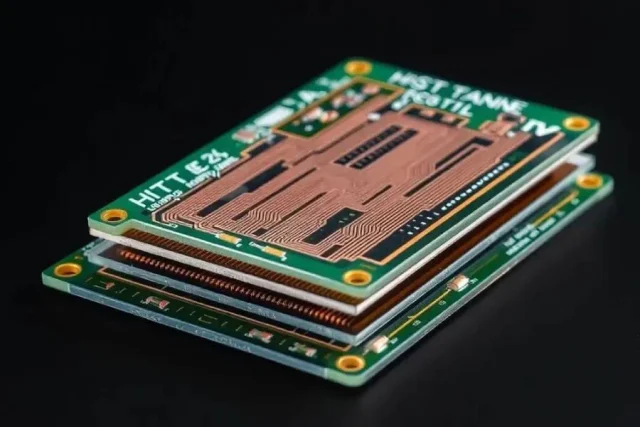

Design Considerations for High TG PCB

Designing a High TG PCB requires attention to:

-

Thermal expansion control (CTE)

-

Stack-up symmetry for multilayer PCBs

-

Copper balance and distribution

-

Thermal via placement

-

Surface finish compatibility

-

Long-term reliability under thermal stress

Proper design maximizes the benefits of High Tg materials.

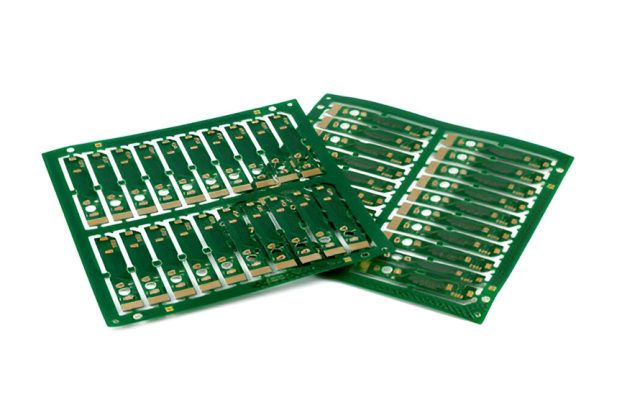

Manufacturing Challenges of High TG PCB

Manufacturing High TG PCBs involves:

-

Controlled lamination temperatures

-

Precise drilling and via reliability

-

Tight process control for multilayer boards

-

High-quality surface finishes

-

Strict thermal and electrical testing

Experienced manufacturers ensure consistent quality.

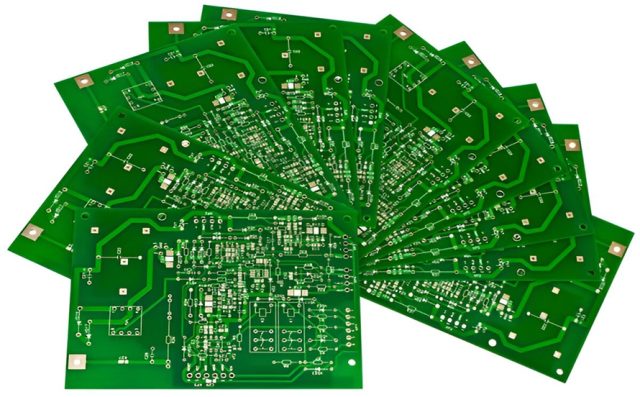

Applications of High TG PCB

High TG PCBs are widely used in:

-

Industrial automation and control systems

-

Automotive electronics

-

Power electronics and heavy copper PCBs

-

High-speed and high-frequency PCBs

-

Medical and aerospace electronics

-

Smart factory and robotics equipment

They are ideal for high-temperature and high-reliability environments.

Conclusion

A High TG PCB provides superior thermal and mechanical stability for demanding electronic applications. With the right materials, optimized design, and advanced manufacturing, High TG PCBs ensure reliable performance under elevated temperatures and harsh operating conditions.

Partnering with an experienced High TG PCB manufacturer ensures consistent quality, long-term reliability, and smooth transition from prototype to production.