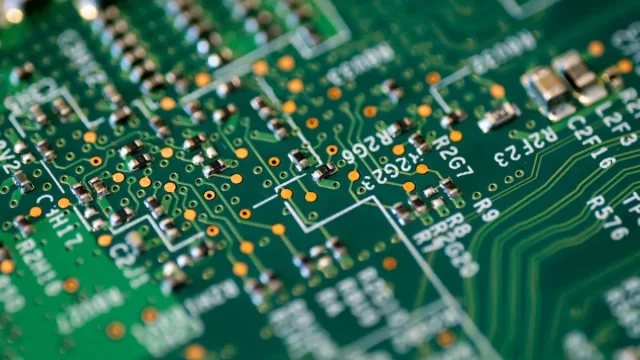

What Are Hybrid PCB Materials?

Hybrid PCB materials refer to printed circuit boards made from a combination of two or more substrate types, such as FR-4, metal-core, PTFE, or ceramic, to achieve specific electrical, thermal, or mechanical properties.

Hybrid PCB materials are widely used in advanced PCB designs, where a single material cannot meet all performance requirements, such as high-frequency signal transmission, thermal dissipation, or mechanical rigidity.

Types of Hybrid PCB Materials

Common hybrid PCB material combinations include:

-

FR-4 + Metal-Core (MCPCB)

Offers mechanical stability and enhanced thermal dissipation for power electronics and LED applications. -

FR-4 + PTFE (Teflon)

Provides low-loss, high-frequency performance for RF, microwave, and high-speed circuits. -

FR-4 + Ceramic

Ensures thermal reliability and minimal expansion in high-power and precision electronics. -

FR-4 + Flexible Polyimide

Combines rigid sections with flexible sections for compact, bendable designs.

By selecting appropriate hybrid PCB materials, designers can optimize both electrical and thermal performance.

Advantages of Hybrid PCB Materials

Using hybrid PCB materials offers several key benefits:

-

Optimized electrical performance

Enables low-loss, controlled impedance for high-speed or RF circuits. -

Enhanced thermal management

Metal-core or ceramic layers improve heat dissipation in high-power applications. -

Mechanical reliability

Rigid + flexible combinations provide strength where needed and flexibility where required. -

Design flexibility

Multiple material types in one board allow innovative and compact PCB layouts. -

Cost efficiency

Achieves high performance without fully relying on expensive specialty substrates.

Manufacturing Considerations for Hybrid PCB Materials

Fabricating a hybrid PCB requires careful process planning to maintain reliability:

-

Layer adhesion and lamination

Different materials must bond properly to prevent delamination. -

Thermal expansion compatibility

Coefficient of thermal expansion (CTE) must be matched to reduce stress. -

Drilling and via plating

Drilling through multiple materials may require specialized tooling and techniques. -

Solder mask and surface finish selection

Ensures consistent performance across material types.

Advanced manufacturing capabilities are critical for producing high-quality hybrid PCB materials reliably.

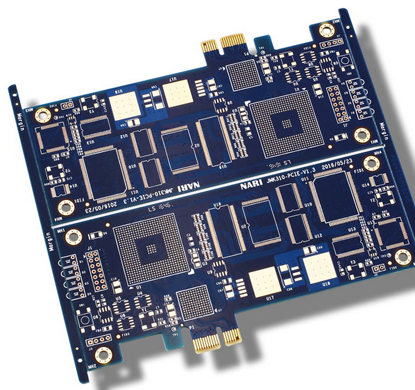

Applications of Hybrid PCB Materials

Hybrid PCB materials are widely used in industries where electrical, thermal, and mechanical performance must be balanced, including:

-

High-frequency RF and microwave circuits

-

LED lighting and power electronics

-

Automotive electronics and ADAS modules

-

Medical devices requiring thermal management

-

Industrial control systems with high power density

Hybrid PCB materials allow designers to meet performance targets that single-material PCBs cannot achieve.

Conclusion

Hybrid PCB materials provide an effective solution for advanced electronics requiring enhanced electrical, thermal, and mechanical properties. By combining different substrate types in a single PCB, engineers can optimize performance while maintaining reliability.

Selecting an experienced manufacturer specializing in hybrid PCB materials ensures high-quality fabrication, precise material integration, and long-term product stability.