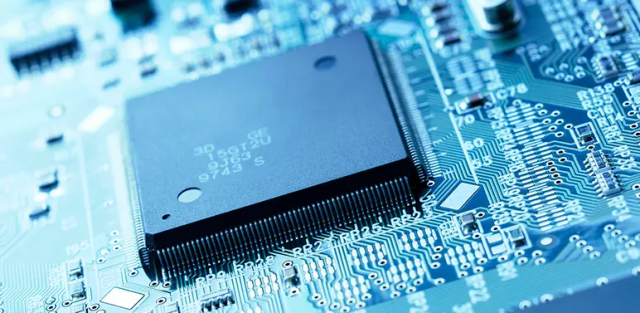

A BT Epoxy PCB is a material system specifically developed to meet the demands of semiconductor packaging, IC substrates, and high-density interconnect structures. Unlike general-purpose FR-4, BT epoxy resin is engineered for environments where thermal stability, dimensional control, and long-term reliability are non-negotiable design constraints.

Material Characteristics of BT Epoxy PCB

BT epoxy, derived from bismaleimide triazine resin chemistry, offers a balance between organic laminate processability and performance characteristics closer to substrate-level materials. Its molecular structure provides enhanced cross-linking density, which directly improves thermal and mechanical behavior.

From an engineering standpoint, BT Epoxy PCB materials provide:

-

High glass transition temperature (Tg) to withstand repeated reflow cycles

-

Low coefficient of thermal expansion (CTE) for dimensional stability

-

Improved rigidity compared to standard epoxy systems

-

Stable dielectric performance across temperature ranges

These properties make BT Epoxy PCB particularly suitable for fine-feature and multilayer constructions.

Thermal Reliability in Packaging Environments

In IC packaging and module applications, the PCB often experiences rapid temperature excursions during assembly and operation. BT Epoxy PCB materials maintain structural integrity under these conditions, reducing risks such as:

-

Warpage during reflow

-

Pad misalignment in fine-pitch layouts

-

Solder joint fatigue caused by CTE mismatch

This thermal reliability directly contributes to higher assembly yield and longer product lifetime.

Electrical Performance and Signal Integrity

While BT Epoxy PCB is not classified as an ultra-low-loss material, it offers stable dielectric behavior suitable for high-speed digital interconnections within packages and modules. Its consistent Dk and controlled thickness support:

-

Predictable impedance routing

-

Reduced signal skew in dense interconnect structures

-

Reliable performance in moderate to high data-rate applications

This makes BT Epoxy PCB a common choice for memory modules, IC substrates, and high-density logic interposers.

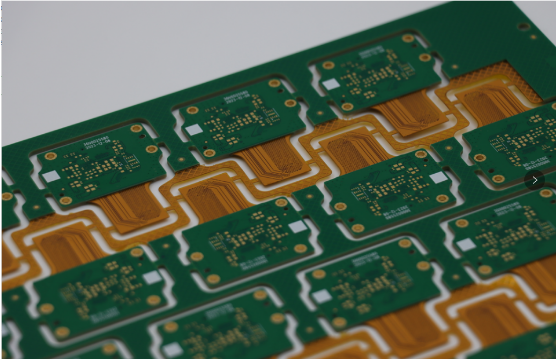

Manufacturability and Process Compatibility

One of the key advantages of BT Epoxy PCB materials is their excellent compatibility with conventional PCB and substrate manufacturing processes. Compared with ceramic or PTFE-based systems, BT epoxy allows:

-

Fine-line etching for high-density routing

-

Laser drilling for microvia formation

-

Multilayer lamination with tight registration control

-

Stable copper adhesion during repeated thermal cycles

This process adaptability makes BT Epoxy PCB suitable for mass production with tight tolerances.

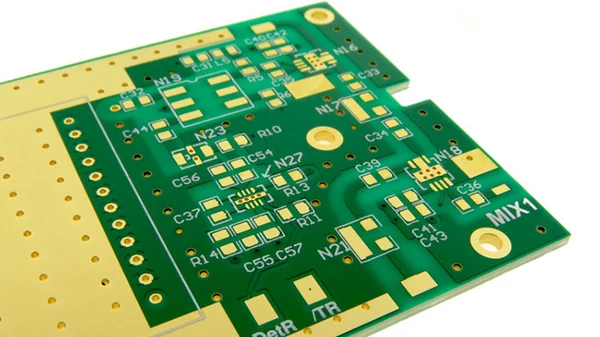

Typical Applications of BT Epoxy PCB

BT Epoxy PCBs are widely used in:

-

IC substrate and package carrier boards

-

Memory modules and high-density logic packages

-

Chip-on-board (COB) and system-in-package (SiP) structures

-

Consumer and industrial electronics requiring compact interconnects

In these applications, BT Epoxy PCB serves as a bridge material between traditional PCBs and advanced semiconductor substrates.

Engineering Perspective

A BT Epoxy PCB is best understood as a reliability-focused interconnect platform rather than a general-purpose laminate. Its value lies in maintaining dimensional accuracy, thermal stability, and manufacturability under packaging-level stress conditions. When properly selected and engineered, BT Epoxy PCB materials enable high-yield assembly and long-term electrical reliability in dense electronic systems.