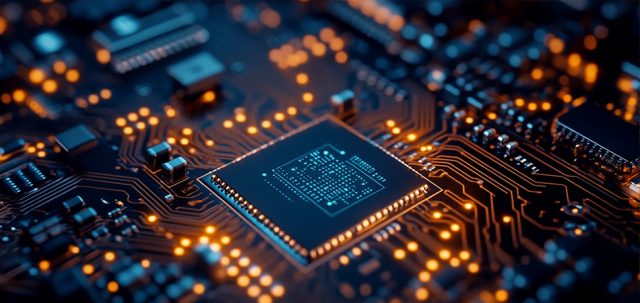

High Tg Materials: A Critical Upgrade for Reliable PCB Performance

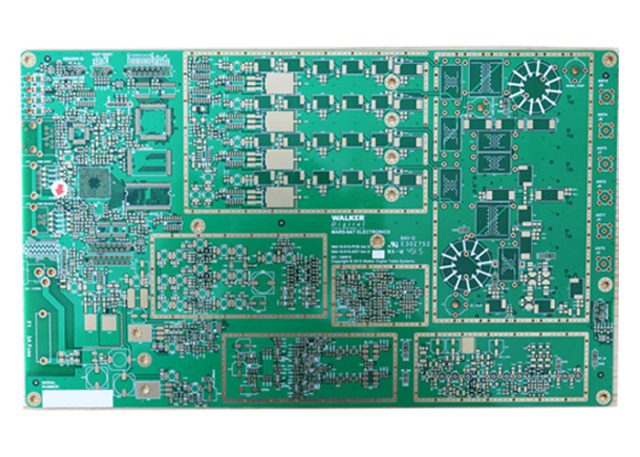

Modern electronic products are operating under increasingly demanding conditions—higher power density, higher assembly temperatures, and more complex multilayer designs. As a result, PCB materials must deliver stronger thermal stability and long-term reliability.

This is why High Tg materials have become a common choice in automotive, industrial, power electronics, and high-reliability applications. By offering a higher glass transition temperature, High Tg laminates help PCBs withstand lead-free reflow, reduce failure risks, and maintain stable mechanical performance over time.

In this article, we’ll explain what High Tg materials are, their benefits, typical applications, and how to choose the right High Tg laminate for your PCB project.

What Are High Tg Materials?

High Tg materials refer to PCB laminates with a higher glass transition temperature (Tg) compared with standard FR4. Tg is the temperature at which the resin system transitions from a rigid state to a softer, rubber-like state.

When a PCB operates or is processed near or above its Tg, the material may experience:

-

Higher expansion (CTE increase)

-

Reduced mechanical strength

-

Increased risk of delamination

-

Higher stress on plated through holes (PTH)

High Tg materials help avoid these issues by maintaining stability at higher temperatures.

Why High Tg Matters in PCB Manufacturing

PCB assembly processes—especially lead-free soldering—require higher peak temperatures than traditional soldering methods. This puts extra stress on the PCB laminate, particularly for:

-

Multilayer boards

-

Thick copper designs

-

High-density interconnect (HDI) structures

-

Rework and multiple thermal cycles

Using High Tg materials improves PCB resistance to thermal damage and helps ensure stable performance during and after assembly.

Key Benefits of High Tg PCB Materials

1. Better Thermal Resistance During Lead-Free Reflow

High Tg laminates are designed to handle higher soldering temperatures with reduced risk of:

-

Resin cracking

-

Blistering

-

Delamination

-

Warpage

This is especially important when PCBs go through multiple reflow cycles.

2. Improved Plated Through Hole (PTH) Reliability

Thermal expansion differences between copper and laminate can stress vias and plated holes. High Tg materials help improve:

-

Via reliability under thermal cycling

-

Resistance to barrel cracking

-

Long-term durability in harsh environments

3. Reduced Delamination Risk in Multilayer PCBs

As layer count increases, internal stress becomes more severe. High Tg materials provide stronger bonding and stability, reducing the chance of:

-

Layer separation

-

Internal voids

-

CAF-related risks in certain designs

4. Stronger Mechanical Stability

High Tg materials support better mechanical performance for demanding PCB structures such as:

-

High layer count stack-ups

-

Thick boards and heavy copper

-

Fine pitch components and dense routing

This helps improve manufacturing yield and product reliability.

Typical Applications for High Tg Materials

Automotive Electronics

High Tg PCB materials are widely used in automotive designs due to:

-

High under-hood temperatures

-

Vibration and thermal cycling

-

Long service life requirements

Typical automotive uses include power control units, ECUs, and EV electronics.

Industrial Control and Power Electronics

Industrial environments often involve high temperatures and continuous operation. High Tg materials are suitable for:

-

Motor drives

-

Power converters

-

Industrial controllers

-

High-current power boards

High-Reliability Electronics

High Tg laminates are also common in reliability-focused applications such as:

-

Communication infrastructure

-

Aerospace and defense systems

-

Medical equipment

High Tg vs Standard FR4: What’s the Difference?

Standard FR4 is suitable for many products, but high Tg materials provide improved thermal stability and reliability.

| Feature | Standard FR4 | High Tg Materials |

|---|---|---|

| Tg Level | Lower | Higher |

| Reflow Resistance | Moderate | Better |

| Delamination Risk | Higher | Lower |

| Via Reliability | Standard | Improved |

| Typical Use | General electronics | High-temp / high-reliability |

How to Choose the Right High Tg Material

When selecting a High Tg laminate, engineers should consider:

-

Assembly process temperature (lead-free reflow)

-

Layer count and board thickness

-

Thermal cycling requirements

-

Copper weight and current load

-

Operating environment and service life

-

Electrical requirements (high-speed / controlled impedance)

A qualified PCB manufacturer can recommend suitable High Tg materials based on your design and reliability targets.

Conclusion

High Tg materials are a smart upgrade for PCBs that must survive higher assembly temperatures, harsh operating environments, and long-term thermal cycling. They help improve delamination resistance, via reliability, and overall thermal stability, making them ideal for automotive, industrial, and high-power electronics.

If your PCB design requires stronger thermal reliability than standard FR4 can provide, High Tg materials are an excellent choice.