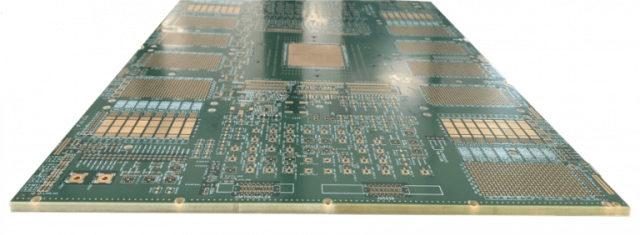

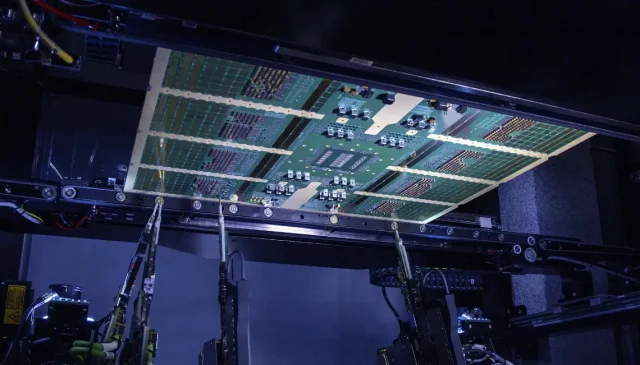

In modern semiconductor testing, probe card assembly PCBs play a vital role in connecting wafer-level devices to automated test equipment (ATE). These specialized PCBs act as the interface between probe cards and the testing system, ensuring high-speed, high-density, and accurate signal transmission for ICs, memory modules, and RF/microwave chips.

High-quality probe card assembly PCBs enable engineers to perform functional, parametric, and wafer-level testing efficiently, ensuring reliable results, minimal errors, and faster time-to-market.

What Is a Probe Card Assembly PCB?

A Probe Card Assembly PCB is a specially designed PCB that integrates with a probe card to facilitate semiconductor wafer testing. Key functions include:

-

Routing high-density signals from wafer pads to ATE systems

-

Providing controlled impedance for high-speed and RF signals

-

Maintaining mechanical stability for accurate probe alignment

-

Supporting high pin count ICs and fine-pitch memory or RF devices

These PCBs are engineered to deliver precision, repeatability, and reliability in demanding semiconductor test environments.

Key Features of Probe Card Assembly PCBs

-

High-Density Signal Routing

Supports complex ICs, memory modules, and RF chips with hundreds or thousands of I/O pins. -

Controlled Impedance

Ensures accurate high-speed signal transmission, minimizing crosstalk and signal reflections. -

Multilayer HDI Design

Separates power, ground, and signal layers to optimize signal integrity for high-frequency applications. -

Mechanical Precision

Maintains probe card alignment, reduces pad damage, and ensures consistent testing over multiple cycles. -

Thermal and Electrical Reliability

Withstands repeated test cycles, burn-in testing, and high-current or high-frequency applications.

Materials and Stackup Considerations

Selecting the proper materials and stackup is crucial for probe card assembly PCB performance:

-

High-Tg FR-4 – Suitable for standard IC and memory module testing

-

Low-Loss Laminates – Required for RF/microwave chip testing

-

Hybrid Stackups – Combine FR-4 and low-loss cores for optimal signal integrity

-

Thermally Stable Materials – Maintain mechanical stability during burn-in or high-current testing

Correct material selection ensures signal integrity, low loss, and reliable probe alignment.

Applications of Probe Card Assembly PCBs

Probe card assembly PCBs are widely used in:

-

Wafer-level IC testing using ATE systems

-

Memory module validation (DRAM, SRAM, Flash)

-

RF and microwave chip functional and parametric testing

-

High-speed and high-frequency semiconductor validation

-

Prototype and small-batch testing before full-scale production

These applications require high-density routing, controlled impedance, mechanical precision, and repeatable performance, all delivered by expertly designed probe card assembly PCBs.

Choosing a Probe Card Assembly PCB Manufacturer

When selecting a manufacturer, key factors include:

-

Experience in high-density, multilayer, and high-pin-count PCB fabrication

-

Expertise with controlled impedance and low-loss materials for high-speed or RF applications

-

Support for prototype, small-batch, and volume production

-

Strong quality control and electrical verification processes

-

Engineering support for design iteration and test system integration

A professional partner ensures accurate, repeatable, and reliable probe card testing for all semiconductor applications.

Conclusion

Probe Card Assembly PCBs are essential for semiconductor wafer-level testing, providing high-density routing, controlled impedance, mechanical stability, and thermal reliability. Partnering with an experienced manufacturer ensures accurate IC, memory, and RF/microwave testing, faster design validation, and a smooth transition from prototype to full-scale production.