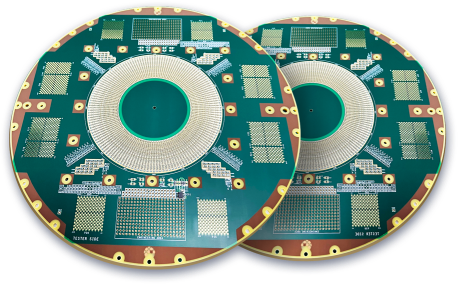

In advanced semiconductor manufacturing, wafer-level testing demands extreme precision and consistency. Probe Card PCB Assembly is a critical process that directly affects test accuracy, yield stability, and long-term reliability. Unlike conventional PCB assembly, probe card PCB assembly requires ultra-tight tolerances, stable mechanical structures, and controlled electrical performance.

A professionally executed probe card PCB assembly ensures accurate signal transmission between automated test equipment (ATE) and the device under test (DUT).

What Makes Probe Card PCB Assembly Unique?

Probe Card PCB Assembly involves assembling high-density, high-layer-count PCBs that interface directly with probe needles or MEMS probes. These PCBs must support:

-

Ultra-high pin count interconnections

-

Fine-pitch probe interfaces

-

High-speed and mixed-signal testing

Every probe card PCB assembly is customized to match specific wafer layouts and test requirements.

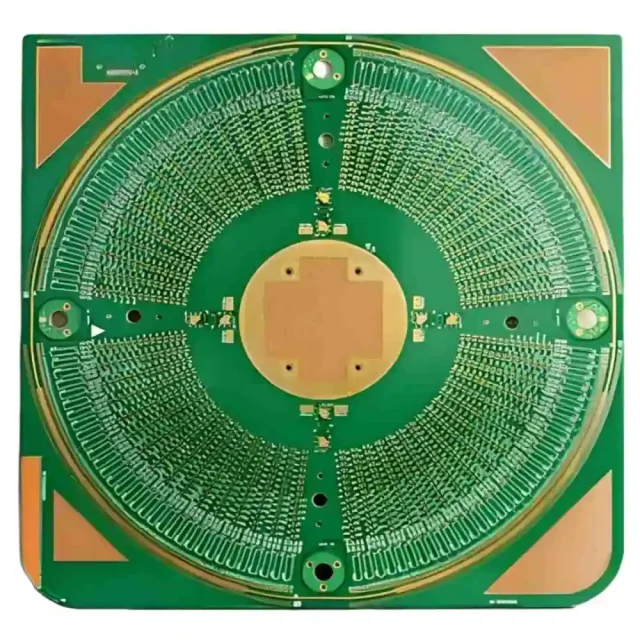

Precision Requirements in Probe Card PCB Assembly

Precision is the defining characteristic of probe card PCB assembly. Key requirements include:

-

Accurate component placement for high-speed connectors

-

Strict control of coplanarity and flatness

-

Stable alignment between PCB, stiffener, and probe structure

Even minor deviations can impact probing accuracy and repeatability.

Signal Integrity in Probe Card PCB Assembly

Modern wafer-level testing operates at increasingly higher frequencies. Probe card PCB assembly must preserve signal integrity by:

-

Minimizing parasitic inductance and capacitance

-

Maintaining controlled impedance throughout assembled interfaces

-

Reducing signal discontinuities at solder joints and connectors

Proper assembly ensures clean, repeatable measurement results.

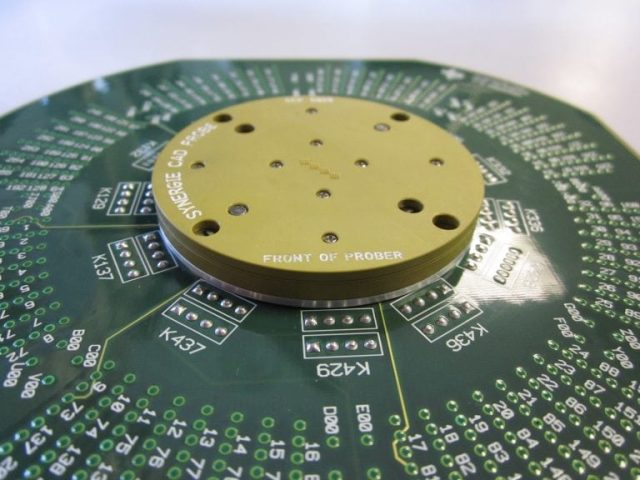

Power Integrity and Noise Control

Reliable probe card PCB assembly also focuses on power delivery and grounding. This includes:

-

Low-impedance power paths

-

Robust ground connections

-

Effective noise isolation between signal domains

Stable power integrity prevents false failures during testing.

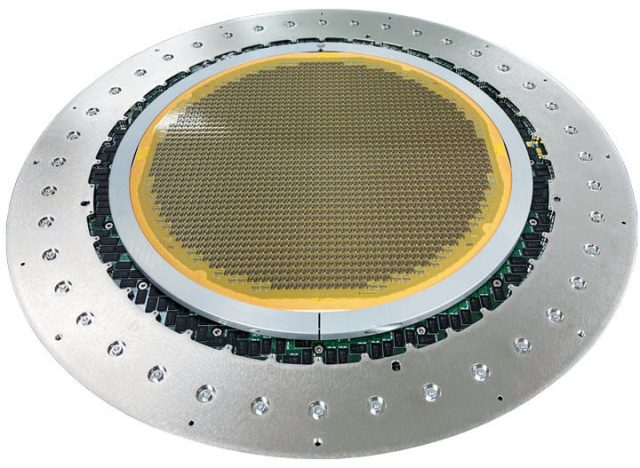

Mechanical Stability and Long-Term Reliability

Probe cards experience repeated contact cycles and thermal variation. High-quality probe card PCB assembly ensures:

-

Strong solder joint reliability

-

Resistance to mechanical stress and vibration

-

Long-term dimensional stability

Mechanical reliability is essential for consistent wafer probing.

Quality Control in Probe Card PCB Assembly

Given the critical nature of semiconductor testing, probe card PCB assembly requires advanced inspection, including:

-

Automated optical inspection (AOI)

-

X-ray inspection for hidden solder joints

-

Electrical continuity and impedance verification

Comprehensive quality control minimizes latent defects.

Small Batch and Production Probe Card PCB Assembly

Probe card PCB assembly often supports:

-

Engineering and characterization builds

-

Qualification and reliability testing

-

Repeatable small-batch and production assembly

Consistent assembly processes ensure uniform performance across multiple probe cards.

Applications of Probe Card PCB Assembly

Probe card PCB assemblies are widely used in:

-

Wafer-level IC testing

-

Logic, memory, and RF semiconductor probing

-

Advanced-node device characterization

-

High-speed and mixed-signal test platforms

Each application demands high precision and stability.

Choosing a Probe Card PCB Assembly Manufacturer

When selecting a probe card PCB assembly supplier, key considerations include:

-

Proven experience with semiconductor testing PCBs

-

Capability for fine-pitch, high-density PCB assembly

-

Strong process control and quality systems

-

Engineering support for NPI and yield optimization

An experienced partner ensures reliable and scalable assembly solutions.

Conclusion

Probe Card PCB Assembly is a mission-critical process in wafer-level semiconductor testing. By combining precision assembly, stable signal integrity, and rigorous quality control, professional probe card PCB assembly enables accurate testing, higher yield, and long-term reliability.

Choosing a specialized probe card PCB assembly manufacturer is essential for achieving consistent and repeatable test performance in advanced semiconductor applications.