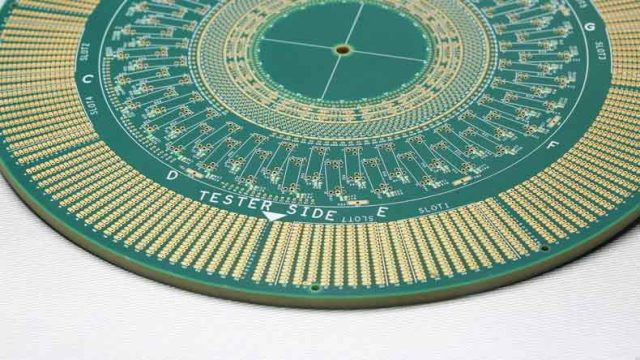

In semiconductor mass production, test throughput and consistency are just as important as accuracy. The Load Board PCB is a critical interface between automated test equipment (ATE) and packaged semiconductor devices, ensuring reliable electrical connection and repeatable test performance during high-volume production.

A well-designed Load Board PCB minimizes downtime, reduces false failures, and supports long-term production stability.

What Is a Load Board PCB?

A Load Board PCB is a specialized printed circuit board used in final test and system-level test environments. It provides:

-

Electrical interconnection between ATE channels and DUT pins

-

Power delivery and grounding networks for packaged devices

-

Mechanical support for test sockets and fixtures

Load board PCBs are designed for durability and repeated use in production testing.

The Role of Load Board PCBs in Semiconductor Testing

Load board PCBs are typically used after wafer probing and package-level validation. Their main roles include:

-

Verifying device functionality in production conditions

-

Supporting high-speed and high-pin-count device testing

-

Enabling high-throughput automated testing

Reliability at this stage directly affects yield and cost.

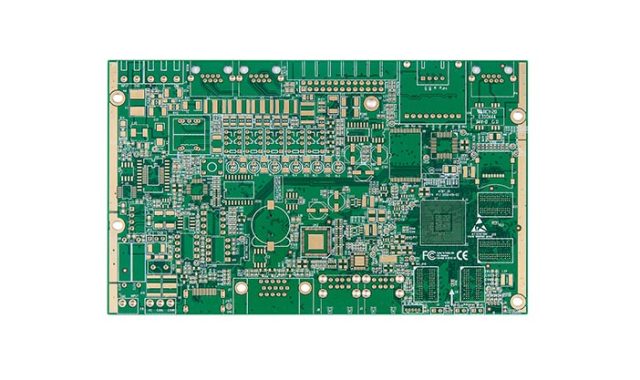

Signal Integrity for High-Speed Load Board PCBs

High-speed digital and RF devices require precise signal control. Load board PCB designs incorporate:

-

Controlled impedance routing

-

Length matching for timing-critical signals

-

Clean return path and reference plane design

Good signal integrity ensures accurate test results at production speeds.

Power Integrity and Thermal Considerations

Production testing often involves high current and long test cycles. A Load Board PCB must provide:

-

Low-impedance power planes

-

Robust decoupling and bulk capacitance

-

Thermal stability under continuous operation

Stable power delivery reduces noise-induced test failures.

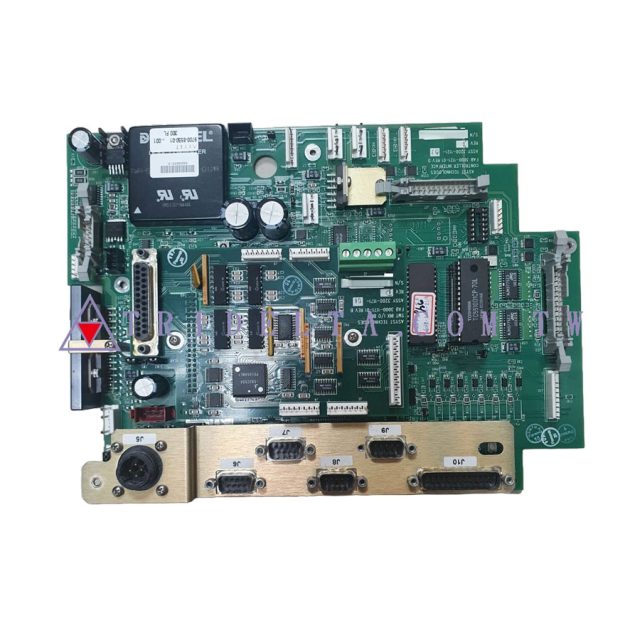

Supporting High Pin Count and Dense Routing

Modern IC packages often exceed hundreds or thousands of pins. Load board PCBs support:

-

Multilayer and HDI PCB structures

-

Fine-pitch breakout and via-in-pad technology

-

Optimized routing for dense pin maps

High-density capability enables full device coverage.

Mechanical Strength and Socket Integration

Load Board PCBs experience frequent socket insertions and mechanical stress. Reliable designs include:

-

Reinforced socket mounting areas

-

Tight flatness and coplanarity control

-

Warpage-resistant stackup design

Mechanical robustness ensures long-term test stability.

Material Selection for Load Board PCBs

Material choice affects both durability and electrical performance. Common options include:

-

High-Tg FR-4 for mechanical strength

-

Low-loss laminates for high-speed signals

-

Hybrid stackups for mixed-signal testing

Materials are selected based on device speed and test environment.

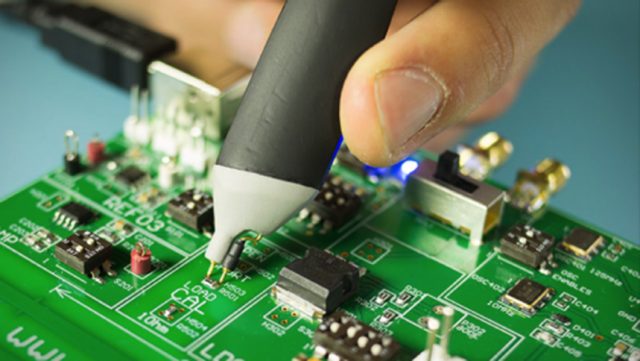

Manufacturing Precision and Quality Control

Consistency is critical for production testing. High-quality Load Board PCBs require:

-

Tight laminate thickness control

-

Accurate drilling, plating, and etching

-

Electrical and impedance verification

Manufacturing precision ensures consistent test performance across builds.

Typical Applications of Load Board PCBs

Load Board PCBs are widely used in:

-

Final test of logic and memory devices

-

Automotive and industrial IC production

-

High-speed communication and processor testing

-

System-level test (SLT) environments

Each application demands high reliability and repeatability.

Choosing a Load Board PCB Manufacturing Partner

When selecting a Load Board PCB manufacturer, consider:

-

Experience with high-volume semiconductor testing

-

High pin count and controlled impedance capability

-

Proven mechanical reliability in production use

-

Engineering support for complex socket integration

The right partner helps reduce downtime and test cost.

Conclusion

The Load Board PCB is a cornerstone of reliable semiconductor production testing. By ensuring strong signal integrity, stable power delivery, mechanical durability, and manufacturing consistency, a well-designed load board PCB enables efficient, repeatable, and scalable high-volume testing.

Partnering with an experienced Load Board PCB supplier is essential for long-term production success.