In modern semiconductor production, test accuracy must remain stable not only for one device, but across tens of thousands—or even millions—of test cycles. While ATE systems continue to advance in speed and precision, the ATE test PCB remains a decisive factor in determining whether test results are repeatable, reliable, and production-ready.

A professionally engineered ATE test PCB minimizes test variation, reduces false failures, and protects overall test yield throughout the product lifecycle.

What Makes an ATE Test PCB Different?

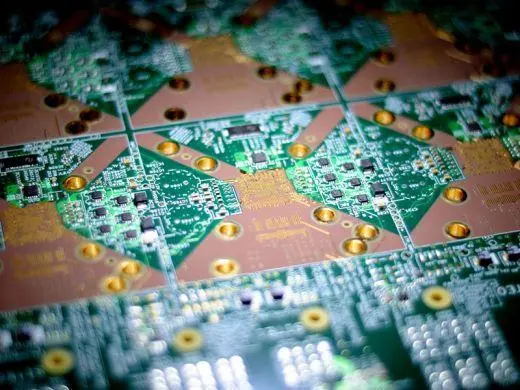

An ATE test PCB is a dedicated interface board that electrically connects automated test equipment to the device under test (DUT). Unlike standard functional PCBs,ATE Test PCB are designed to prioritize measurement stability over long-term operation.

Key differences include:

-

Extremely tight electrical tolerance control

-

Support for high pin count and mixed-signal testing

-

Resistance to electrical and mechanical fatigue

-

Repeatable performance across extended test runs

These requirements make ATE test PCBs a specialized category within semiconductor test hardware.

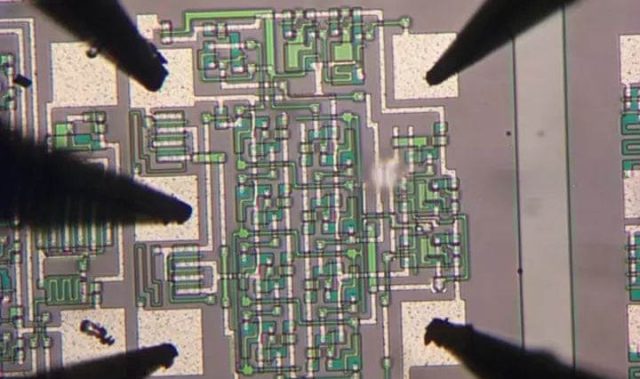

Test Accuracy Depends on ATE Test PCB Consistency

In high-speed IC testing, even small variations in the ATE test PCB can cause:

-

Timing shifts and skew

-

Signal amplitude inconsistency

-

Power noise coupling into sensitive measurements

-

Gradual test window drift

A high-quality ATE test PCB ensures that every DUT is tested under the same electrical conditions, regardless of test duration or volume.

Signal Integrity in High-Speed ATE Test PCBs

As test speeds increase, ATE test PCB signal integrity becomes critical. Effective designs incorporate:

-

Controlled impedance routing across all high-speed channels

-

Symmetrical signal path layout

-

Dedicated reference planes to maintain return paths

These features help prevent reflections, crosstalk, and measurement distortion during fast switching.

Power Integrity and Load Stability

ATE test PCBs must deliver stable power under rapidly changing load conditions. Poor power integrity can result in:

-

False failures

-

Inconsistent parametric results

-

Masked device defects

Professional ATE test PCB design includes low-impedance power planes, optimized decoupling placement, and robust grounding structures to maintain voltage stability during testing.

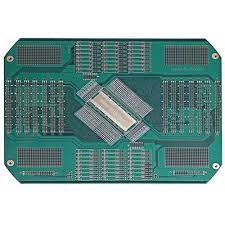

Mechanical Reliability and Test Repeatability

ATE test PCBs experience constant mechanical interaction through sockets, connectors, and fixtures. Long-term reliability depends on:

-

Excellent PCB flatness

-

Reinforced high-stress areas

-

Stackup symmetry to reduce warpage

Mechanical stability directly affects electrical contact quality and test repeatability.

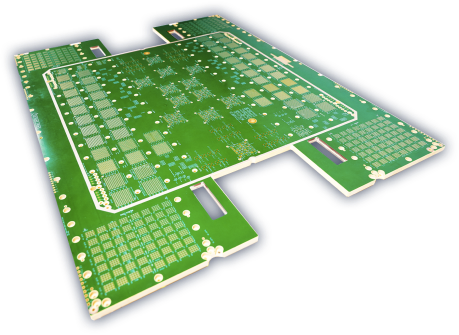

Materials and Stackup Strategy for ATE Test PCBs

Material selection is driven by stability rather than cost:

-

High-Tg FR-4 for durability

-

Low-loss laminates for high-speed test channels

-

Hybrid stackups for mixed-signal environments

Stable dielectric properties ensure consistent electrical behavior over time and temperature.

Manufacturing Repeatability Is Critical

Unlike one-off prototypes, ATE test PCBs must deliver identical performance across multiple builds. This requires:

-

Tight laminate thickness control

-

Consistent copper distribution

-

Accurate drilling and via plating

-

Electrical and impedance verification

Manufacturing variation directly translates into test variation.

Typical Applications of ATE Test PCBs

ATE test PCBs are widely used in:

-

IC final test and system-level test

-

Automotive semiconductor qualification

-

High-speed logic and memory testing

-

Power and mixed-signal device validation

Each application demands long-term electrical consistency.

Choosing an ATE Test PCB Manufacturing Partner

When selecting an ATE test PCB manufacturer, key considerations include:

-

Proven experience in semiconductor test PCBs

-

Controlled impedance and high pin count capability

-

Strong process consistency and traceability

-

Fast response for test board revisions

A reliable partner helps maintain stable test results throughout production.

Conclusion

The ATE test PCB is not just an interface—it is a core component that defines test accuracy, yield stability, and production efficiency. By focusing on signal integrity, power stability, mechanical reliability, and manufacturing consistency, a high-quality ATE test PCB ensures that automated testing remains accurate from the first unit to mass production.

Partnering with an experienced ATE test PCB supplier is essential for achieving repeatable, trustworthy semiconductor test results.