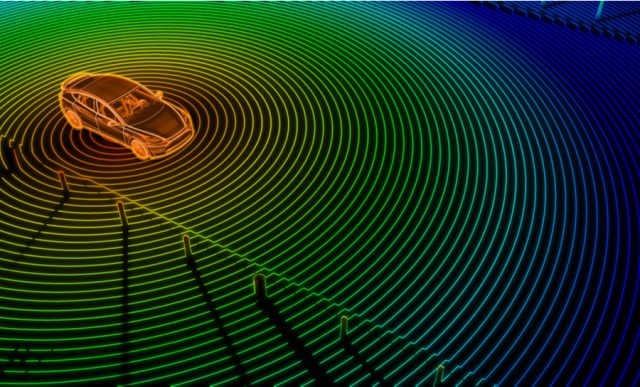

Automotive radar is a cornerstone technology for ADAS and autonomous driving, providing precise object detection in all weather and lighting conditions. Behind every reliable radar sensor is a carefully engineered automotive radar PCB, where manufacturing accuracy directly affects detection range, resolution, and system reliability.

Automotive radar PCB manufacturing is not only about high frequency—it is about long-term stability, repeatability, and compliance with automotive-grade standards.

Automotive Radar Systems and PCB Performance Demands

Modern automotive radar systems typically operate at:

-

24 GHz for short-range sensing

-

77 GHz / 79 GHz for mid- and long-range detection

At these frequencies, minor deviations in dielectric thickness, copper roughness, or impedance can lead to measurable performance degradation. This makes automotive radar PCB manufacturing significantly more demanding than conventional RF PCB production.

Material Engineering for Automotive Radar PCBs

Material selection is a foundational decision in automotive radar PCB manufacturing. Common materials include:

-

Rogers RO3003 / RO4350 series

-

PTFE-based low-loss laminates

-

Duroid 5880 for ultra-low loss radar paths

-

Hybrid stackups combining RF laminates with high-Tg FR-4

Key material requirements include:

-

Low and stable dielectric constant (Dk)

-

Ultra-low dissipation factor (Df)

-

Thermal and mechanical stability across vehicle operating conditions

Controlled Impedance and Phase Consistency

Radar accuracy depends heavily on phase stability and impedance matching. Professional automotive radar PCB manufacturing includes:

-

Precise RF stackup modeling

-

Tight dielectric thickness tolerance

-

Controlled impedance fabrication (±5% or tighter)

-

Impedance and phase verification using TDR and RF testing

These controls ensure predictable radar signal propagation.

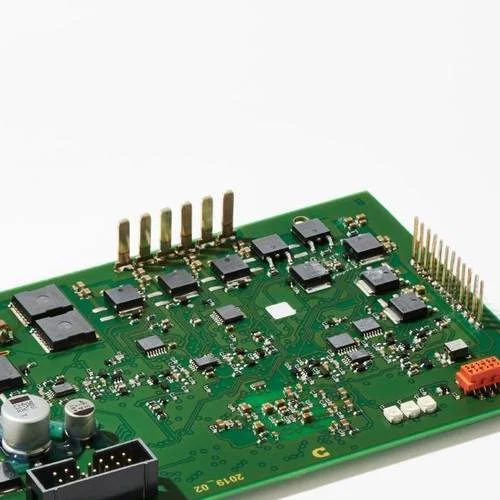

Manufacturing Process Control for mmWave Radar PCBs

To support reliable mmWave operation, manufacturers must manage:

-

Fine-line etching accuracy for high-frequency traces

-

Copper surface roughness to minimize conductor loss

-

Via drilling and plating precision

-

Multilayer lamination stability and registration

Consistent process control is essential to ensure radar PCBs perform identically across production batches.

Automotive-Grade Reliability Requirements

Unlike consumer electronics, automotive radar PCB manufacturing must address harsh operating environments:

-

Wide temperature cycling

-

Continuous vibration and mechanical stress

-

Long service life expectations

Manufacturing processes must prioritize reliability, traceability, and consistency rather than short-term cost optimization.

Radar PCB Applications in Automotive Systems

Automotive radar PCBs are used in:

-

Adaptive Cruise Control (ACC)

-

Automatic Emergency Braking (AEB)

-

Blind Spot Detection (BSD)

-

Lane Change Assistance

-

Autonomous driving perception platforms

Each application places strict demands on PCB electrical stability and manufacturing repeatability.

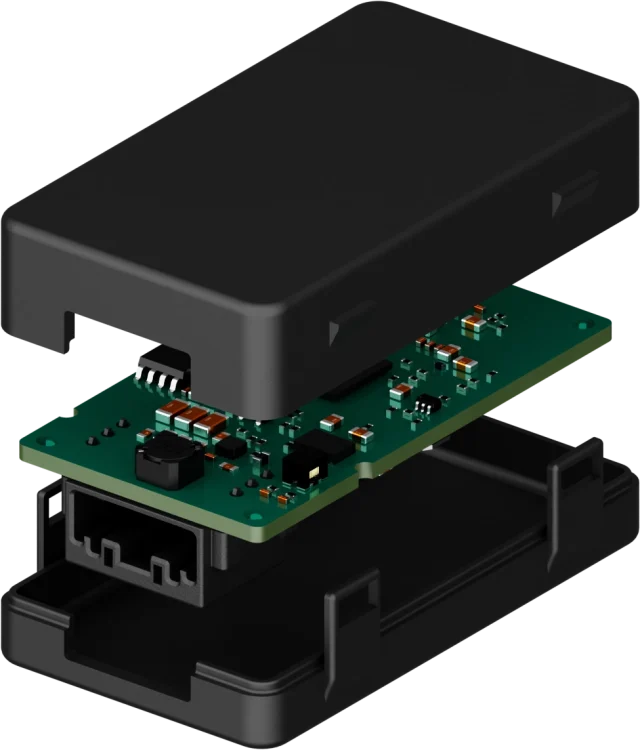

Prototype to Mass Production Considerations

A capable automotive radar PCB manufacturer supports:

-

Engineering prototypes for radar tuning

-

Pilot runs for process validation

-

Stable mass production with consistent RF performance

Smooth transition from prototype to volume production is critical for automotive programs.

Selecting an Automotive Radar PCB Manufacturing Partner

When choosing a partner, OEMs and Tier-1 suppliers should evaluate:

-

Proven experience in mmWave radar PCB manufacturing

-

Expertise with low-loss RF and PTFE materials

-

Controlled impedance and RF testing capability

-

Automotive-grade quality systems and traceability

-

Ability to support long-term, high-volume production

A qualified manufacturer becomes a strategic partner in radar system success.

Conclusion

Automotive radar PCB manufacturing is a specialized discipline that combines mmWave RF engineering with automotive-grade reliability and production consistency. Through precise material control, impedance management, and tightly regulated manufacturing processes, high-quality radar PCBs enable accurate sensing and dependable ADAS performance.

Choosing the right automotive radar PCB manufacturing partner ensures stable radar performance today—and scalability for future autonomous driving platforms.