Automotive radar systems are a core component of ADAS and autonomous driving technologies, enabling functions such as adaptive cruise control, collision avoidance, and blind-spot detection. At the heart of these systems lies the automotive radar PCB, where manufacturing precision directly impacts detection accuracy and long-term reliability.

Automotive radar PCB manufacturing requires far more stringent control than standard PCB fabrication, combining high-frequency performance with automotive-grade reliability.

Radar Frequency Bands and PCB Requirements

Automotive radar typically operates at:

-

24 GHz (short-range radar)

-

77 GHz / 79 GHz (long- and mid-range radar)

At these frequencies, even small variations in PCB material or geometry can significantly affect signal loss, phase stability, and antenna performance. This makes automotive radar PCB manufacturing highly sensitive to process control.

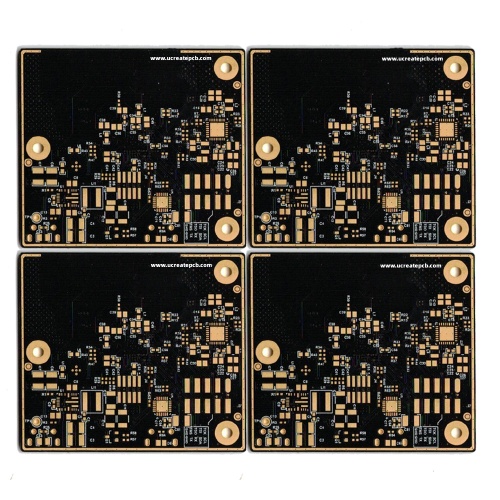

Material Selection for Automotive Radar PCBs

A professional automotive radar PCB manufacturer carefully selects low-loss, stable materials such as:

-

Rogers RO3003 / RO4350 series

-

PTFE-based laminates

-

Duroid 5880 for ultra-low loss radar modules

-

Hybrid stackups combining RF materials with high-Tg FR-4

Low dielectric loss (Df) and stable dielectric constant (Dk) are essential for mmWave radar performance.

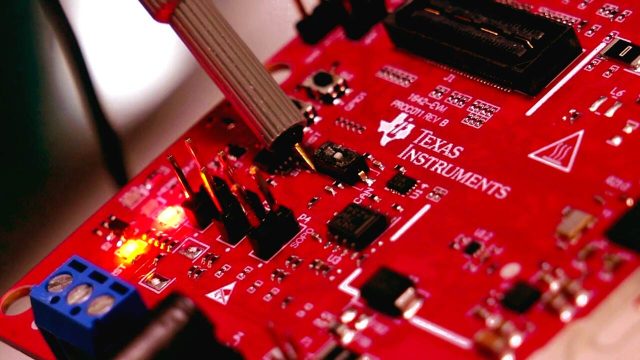

Controlled Impedance and Signal Integrity

Radar systems rely on precise impedance matching. Automotive radar PCB manufacturing includes:

-

Accurate stackup modeling and impedance calculation

-

Tight control of dielectric thickness and copper geometry

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance testing and verification

These measures ensure minimal signal reflection and accurate radar signal transmission.

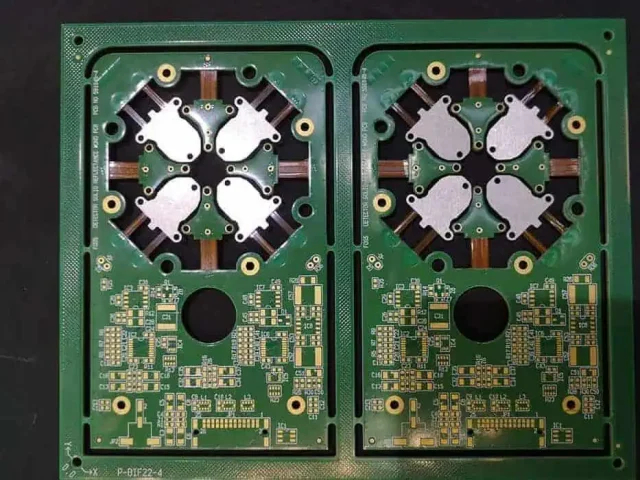

Manufacturing Challenges in Automotive Radar PCBs

Producing reliable radar PCBs involves overcoming several challenges:

-

Fine-line etching for mmWave RF traces

-

Copper roughness control to reduce conductor loss

-

High-precision drilling and via plating

-

Stable lamination for multilayer and hybrid stackups

Experienced manufacturers implement strict process monitoring to maintain consistency.

Automotive Reliability and Quality Requirements

Beyond RF performance, automotive radar PCB manufacturing must meet demanding reliability standards:

-

Thermal cycling resistance

-

Vibration and mechanical stress tolerance

-

Long-term material stability

-

Traceability and process consistency

These requirements ensure radar systems operate reliably throughout a vehicle’s lifetime.

Applications of Automotive Radar PCBs

Automotive radar PCBs are used in:

-

Adaptive Cruise Control (ACC)

-

Automatic Emergency Braking (AEB)

-

Blind Spot Detection (BSD)

-

Lane Change Assistance

-

Autonomous driving perception systems

Each application demands high accuracy and reliability.

Choosing the Right Automotive Radar PCB Manufacturer

When selecting a partner for automotive radar PCB manufacturing, consider:

-

Proven experience with mmWave and radar PCBs

-

Expertise in low-loss materials and hybrid stackups

-

Controlled impedance and RF testing capability

-

Automotive-grade quality management and traceability

-

Ability to scale from prototype to mass production

A reliable manufacturer acts as a long-term technology partner.

Conclusion

Automotive radar PCB manufacturing combines advanced RF engineering with automotive-grade reliability requirements. By using low-loss materials, precise impedance control, and strict process management, radar PCBs deliver accurate sensing and dependable performance for ADAS and autonomous driving systems.

Partnering with an experienced automotive radar PCB manufacturer ensures your radar modules meet the highest standards of performance, consistency, and long-term reliability.