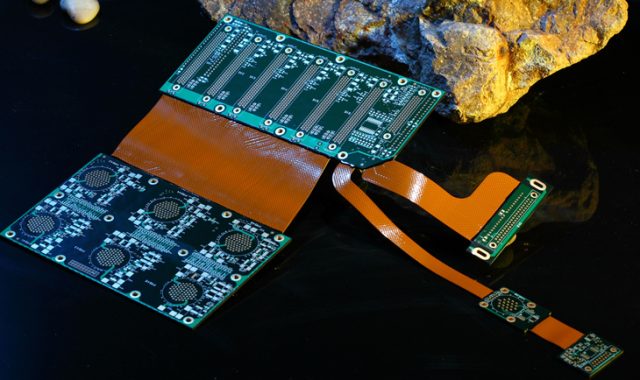

As electronic products continue to become smaller, lighter, and more complex, traditional rigid PCBs often reach their physical and functional limits. Multilayer rigid-flex PCBs combine rigid board stability with flexible circuit adaptability, enabling highly integrated and reliable designs. Working with a professional multilayer rigid-flex PCB manufacturer is essential to achieving consistent quality and long-term reliability.

What Is a Multilayer Rigid-Flex PCB?

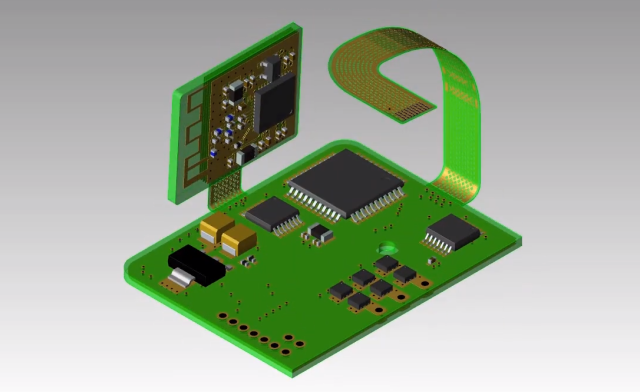

A multilayer rigid-flex PCB integrates multiple rigid PCB layers with one or more flexible circuit layers into a single interconnected structure. Unlike simple flex or rigid boards, rigid-flex PCBs eliminate connectors and cables, improving signal integrity and mechanical reliability.

This architecture is ideal for compact and dynamic electronic assemblies.

Structural Advantages of Multilayer Rigid-Flex PCBs

A qualified multilayer rigid-flex PCB manufacturer enables designs that offer:

-

Reduced assembly size and weight

-

Improved electrical reliability by eliminating connectors

-

Enhanced signal integrity for high-speed and high-frequency signals

-

Better mechanical durability in dynamic environments

These advantages make rigid-flex PCBs a preferred solution for advanced electronic systems.

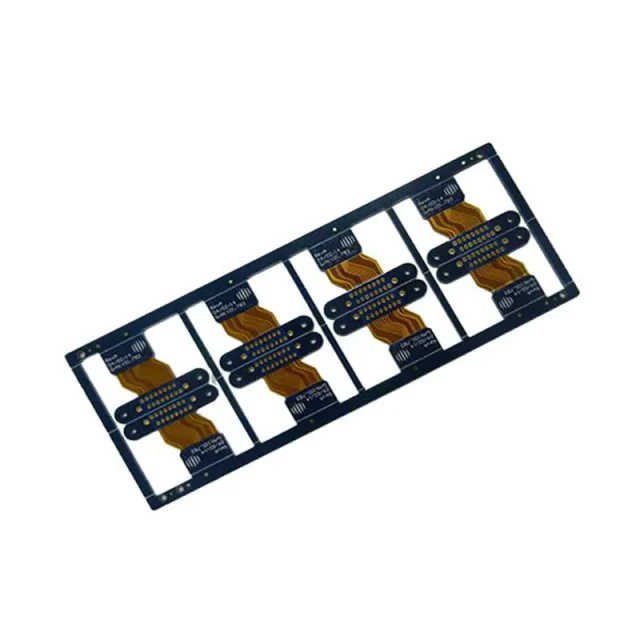

Manufacturing Challenges in Multilayer Rigid-Flex PCBs

Producing multilayer rigid-flex PCBs requires advanced process control. A professional multilayer rigid-flex PCB manufacturer must manage:

-

Precise layer alignment between rigid and flex sections

-

Controlled lamination cycles for mixed materials

-

Reliable via interconnection between rigid and flexible layers

-

Stress management to prevent flex cracking or delamination

These challenges demand specialized equipment and experienced engineering teams.

Materials Used by Multilayer Rigid-Flex PCB Manufacturers

Material selection is critical. Experienced manufacturers work with:

-

Polyimide-based flexible laminates

-

High-TG FR-4 for rigid sections

-

Adhesiveless flex materials for improved reliability

-

Coverlays and stiffeners tailored to application needs

Proper material matching ensures electrical stability and mechanical endurance.

Electrical Performance and Signal Integrity

A professional multilayer rigid-flex PCB manufacturer also considers:

-

Controlled impedance routing across rigid and flex transitions

-

Stable grounding and shielding structures

-

Low-loss materials for high-speed or RF signals

This ensures consistent performance even in complex 3D assemblies.

Applications of Multilayer Rigid-Flex PCBs

Multilayer rigid-flex PCBs are widely used in:

-

Medical devices and wearable electronics

-

Aerospace and defense systems

-

Automotive electronics and sensors

-

Industrial automation equipment

-

High-density consumer electronics

These applications demand high reliability and compact design.

Choosing the Right Multilayer Rigid-Flex PCB Manufacturer

When selecting a multilayer rigid-flex PCB manufacturer, consider:

-

Proven experience with complex rigid-flex designs

-

In-house engineering and DFM support

-

Quality control and reliability testing capabilities

-

Ability to scale from prototype to mass production

The right partner ensures both design success and manufacturing stability.

Conclusion

A professional multilayer rigid-flex PCB manufacturer enables advanced electronic designs that require compact form factors, mechanical flexibility, and electrical reliability. By mastering material integration, process control, and signal integrity management, rigid-flex PCB manufacturers support innovation across high-end electronics markets.

Choosing an experienced multilayer rigid-flex PCB manufacturer ensures consistent quality, reduced assembly complexity, and long-term product reliability.