In a competitive electronics market, sourcing printed circuit boards from a PCB supplier direct—a factory-level manufacturer rather than an intermediary—provides clear advantages in price transparency, communication efficiency, quality control, and production reliability.

A true PCB supplier direct partner enables engineers and procurement teams to access direct factory pricing, faster engineering feedback, and high-performance PCB manufacturing from prototype to mass production.

What Is a PCB Supplier Direct?

A PCB supplier direct refers to a printed circuit board manufacturer that sells and manufactures PCBs directly for customers, bypassing distributors, brokers, and resellers. In this model, buyers interact directly with:

-

PCB process engineers

-

Production planners

-

Quality assurance and testing teams

Direct involvement with the manufacturer improves technical alignment and reduces ambiguity in requirements.

Key Advantages of Working with a PCB Supplier Direct

Transparent Factory Pricing

By working with a PCB supplier direct:

-

You avoid middleman markups

-

Receive cost breakdowns directly from the factory

-

Get engineering-driven cost optimization suggestions

This transparent pricing model helps reduce overall PCB manufacturing cost and supports long-term budgeting.

Faster Engineering Communication

A supplier direct model improves responsiveness:

-

Direct access to PCB engineers

-

Immediate DFM (Design for Manufacturability) feedback

-

Quick resolution of technical queries

This accelerates design validation and shortens the development cycle for PCB prototypes and production orders.

Improved Quality Control and Traceability

A PCB supplier direct manufacturer:

-

Implements in-house quality control at every process stage

-

Performs electrical testing, AOI, and X-ray inspections directly

-

Ensures process traceability from raw materials to finished boards

Direct management of quality control improves consistency and reduces defect rates.

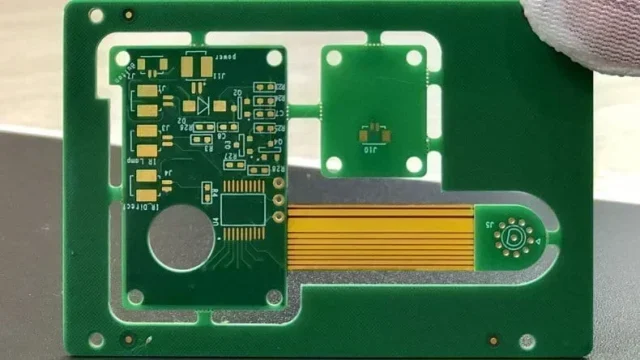

Seamless Prototype to Mass Production

Partnering with a PCB supplier direct enables:

-

Rapid prototype PCB fabrication

-

Small batch pilot runs

-

Scalable volume production

-

Consistent quality across all phases

This ensures continuity from early validation to full-scale manufacturing without unexpected issues.

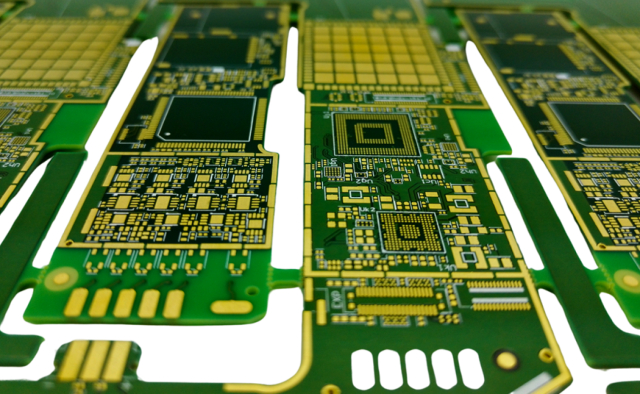

What Capabilities Should a PCB Supplier Direct Offer?

A professional PCB supplier direct should provide:

-

Single-layer to multilayer PCB manufacturing

-

High-frequency, RF, and controlled impedance PCB production

-

Advanced surface finishes (ENIG, OSP, Immersion Silver, etc.)

-

Electrical and functional testing

-

Custom stack-up and material sourcing expertise

These capabilities support diverse applications across consumer, industrial, automotive, and RF systems.

Applications That Benefit from PCB Supplier Direct Services

Direct PCB supply is valuable in industries such as:

-

Consumer electronics and IoT devices

-

Industrial automation and control systems

-

Automotive and ADAS electronics

-

RF, microwave, and high-speed communication systems

-

Aerospace and defense electronics

A PCB supplier direct model ensures stable delivery, cost control, and technical support in complex applications.

How to Choose the Right PCB Supplier Direct Partner

When selecting a PCB supplier direct, consider factors like:

-

Manufacturing experience and scale

-

PCB process capability (RF, high-speed, microvia, controlled impedance)

-

Quality management systems and certifications

-

Engineering communication and support responsiveness

-

Ability to scale from prototype to mass production

The right partner acts not just as a manufacturer, but as a trusted technical ally.

Conclusion

Choosing a PCB supplier direct provides unmatched advantages in cost, quality, speed, and technical alignment. By sourcing PCBs directly from a factory-level manufacturer, companies can secure transparent pricing, faster engineering feedback, tighter quality control, and seamless support from prototype to volume production.

Partnering with a professional PCB supplier direct ensures reliable manufacturing, consistent performance, and long-term supply stability for all your PCB needs.