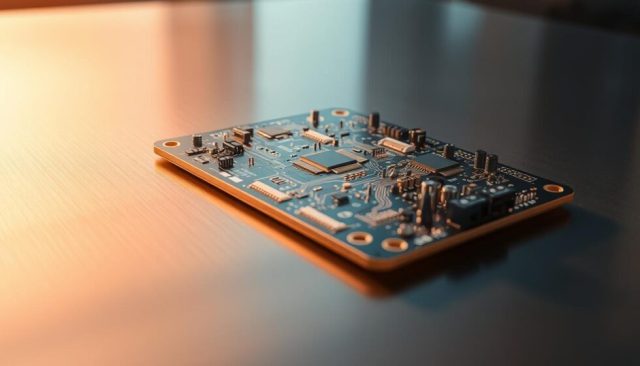

As the Internet of Things (IoT) expands, high-frequency wireless devices require compact, reliable, and high-performance PCBs. A high frequency IoT PCB prototype allows engineers to validate RF performance, signal integrity, and overall design functionality before moving to mass production.

Prototyping high-frequency IoT PCBs enables early detection of design issues, optimization of stackups, and verification of controlled impedance in wireless modules, sensors, and communication devices.

What Is a High Frequency IoT PCB Prototype?

A high frequency IoT PCB prototype is a PCB manufactured with specialized low-loss materials, precise trace geometries, and controlled impedance to support high-speed and RF operation in IoT devices.

These prototypes are typically used in:

-

Wi-Fi, BLE, Zigbee, LoRa, and 5G IoT modules

-

RF front-end circuits and antenna connections

-

Wireless sensor networks and industrial IoT devices

-

Wearable IoT devices

Why High Frequency IoT PCB Prototyping Is Critical

Early Validation of Signal Integrity

High-frequency IoT PCBs require careful impedance and trace design. Prototyping ensures minimal signal reflection and insertion loss.

Material and Stackup Verification

Low-loss laminates like Rogers, Taconic, or PTFE-based materials are verified during the prototype stage to ensure stable RF performance.

Rapid Design Iteration

Prototypes allow engineers to test, refine, and optimize designs before committing to large-scale production.

Reduced Time-to-Market

By identifying potential issues early, high frequency IoT PCB prototypes accelerate development cycles and minimize costly redesigns.

Materials and Design Considerations

Professional high frequency IoT PCB prototype services support:

-

Low-loss laminates for RF and high-speed signals

-

Controlled impedance design for antennas and RF paths

-

Fine-line trace capabilities for compact IoT devices

-

Multilayer PCB stackups to integrate multiple functions in small footprints

Correct material and stackup choices are essential for reliable IoT performance.

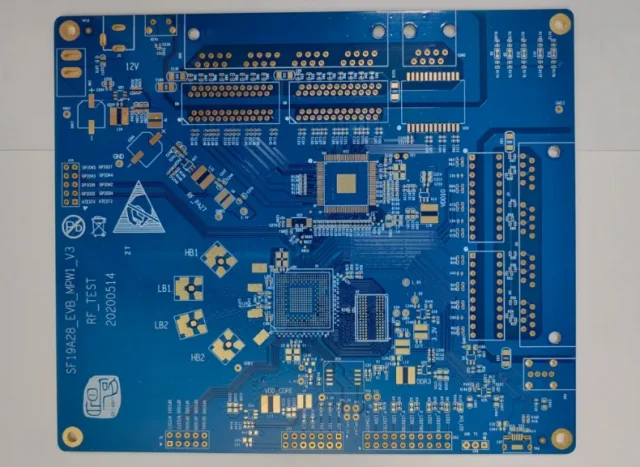

Prototype Manufacturing and Testing

A reliable high frequency IoT PCB prototype manufacturer provides:

-

Small batch prototyping with quick turnaround

-

Controlled impedance fabrication (±5% or tighter)

-

RF and electrical testing to verify functionality

-

DFM feedback and optimization for mass production

These processes ensure prototypes accurately reflect production performance.

Applications of High Frequency IoT PCB Prototypes

High frequency IoT PCB prototypes are used in:

-

Smart home devices (sensors, gateways, and controllers)

-

Industrial IoT modules and wireless automation systems

-

Wearable devices and medical monitoring equipment

-

5G IoT modules and high-speed RF transceivers

Prototyping ensures reliable performance in all these applications.

Choosing a Partner for High Frequency IoT PCB Prototypes

When selecting a high frequency IoT PCB prototype partner, consider:

-

Experience with RF and high-speed IoT PCBs

-

Controlled impedance design and testing capabilities

-

Material selection expertise for low-loss laminates

-

Rapid prototyping and scalable production support

The right partner ensures that prototypes provide accurate feedback for design refinement and mass production readiness.

Conclusion

A high frequency IoT PCB prototype is essential for developing reliable, high-performance wireless and IoT devices. By leveraging low-loss materials, precise impedance control, and RF testing, engineers can validate designs early, optimize performance, and accelerate time-to-market.

Partnering with an experienced high frequency IoT PCB prototype manufacturer ensures accurate, reliable, and production-ready prototypes for next-generation IoT applications.