In today’s global electronics supply chain, many engineers and procurement teams prefer to source printed circuit boards directly from a PCB supplier direct—a factory-level manufacturer that eliminates intermediaries and delivers transparent pricing, faster lead times, and tighter quality control.

A true PCB supplier direct partner provides direct access to PCB manufacturing expertise, supports rapid prototyping, and scales smoothly to volume production. This direct supply model offers clear advantages over traditional trading or distribution channels.

What Does PCB Supplier Direct Mean?

A PCB supplier direct is a PCB manufacturer that deals directly with customers, bypassing distributors and agents. In a supplier direct model, customers communicate directly with:

-

PCB engineers and process specialists

-

Production planning teams

-

Quality assurance and testing departments

Direct communication results in clear requirements, faster technical alignment, and fewer misunderstandings.

Key Advantages of Choosing PCB Supplier Direct

Transparent Factory Pricing

One of the most significant benefits of working with a PCB supplier direct is cost transparency:

-

No distributor or agent markups

-

Direct factory quotes based on real manufacturing cost

-

Clear breakdown of material and process costs

Direct pricing helps customers optimize budgets and negotiate long-term production plans.

Faster Communication and Engineering Feedback

With a PCB supplier direct relationship:

-

Engineering teams respond quickly

-

DFM (Design for Manufacturability) feedback is immediate

-

Technical issues are resolved faster during manufacturing

This reduces development cycles and accelerates time to production.

Better Quality Control from the Source

A PCB supplier direct manufacturer:

-

Controls quality in-house throughout the production process

-

Conducts AOI, X-ray, and electrical testing directly

-

Addresses manufacturing issues at the source

This direct oversight improves PCB yield and reliability.

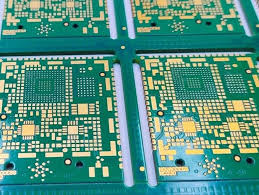

Seamless Transition from Prototype to Production

A qualified PCB supplier direct provider supports:

-

Quick-turn PCB prototyping

-

Small batch pilot runs

-

Volume production scheduling

-

Consistent quality across all production stages

This allows companies to scale efficiently from initial prototypes to commercial volumes.

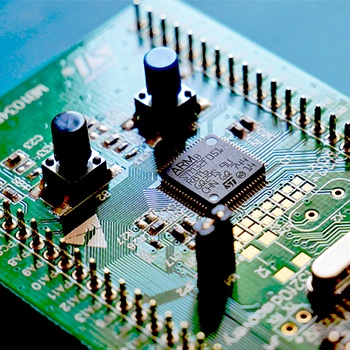

What Capabilities Should a PCB Supplier Direct Offer?

A professional PCB supplier direct should provide:

-

Multilayer PCB fabrication

-

High-frequency, RF, and controlled impedance PCB production

-

Advanced surface finishes (ENIG, OSP, Immersion Silver, etc.)

-

Electrical testing and reliability inspection

-

Custom stack ups and material sourcing support

These capabilities ensure flexible supply for diverse industry needs.

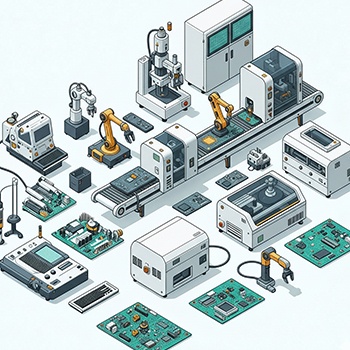

Applications That Benefit from PCB Supplier Direct Services

A PCB supplier direct model serves a wide range of industries, including:

-

Consumer electronics

-

Industrial automation

-

Automotive electronics

-

Wireless communication and RF solutions

-

Medical and aerospace systems

In each of these applications, direct PCB supply reduces risk and improves product stability.

How to Choose the Right PCB Supplier Direct Partner

When selecting a PCB supplier direct, consider:

-

Manufacturing capacity and modern equipment

-

Quality management systems and certifications

-

RF and high-frequency PCB expertise

-

Response time and engineering support

-

Prototype to volume production scalability

The right direct supplier ensures reliable delivery and long-term collaboration.

Conclusion

Opting for a PCB supplier direct—a factory-level PCB manufacturer—provides clear benefits in price transparency, communication efficiency, quality control, and scalable production. By working directly with a trusted PCB supplier, companies can accelerate development, control costs, and ensure consistent product quality from prototype through volume manufacturing.

Partnering with a professional PCB supplier direct manufacturer delivers not just PCBs, but reliable, responsive, and cost-effective manufacturing support.