As electronic products become smaller, lighter, and more complex, the demand for integrated and space-saving interconnect solutions continues to grow. A professional multilayer rigid-flex PCB manufacturer provides advanced manufacturing solutions that combine the mechanical stability of rigid PCBs with the flexibility of flex circuits.

Multilayer rigid-flex PCBs enable compact design, improved reliability, and reduced interconnection complexity for high-end electronic systems.

What Is a Multilayer Rigid-Flex PCB?

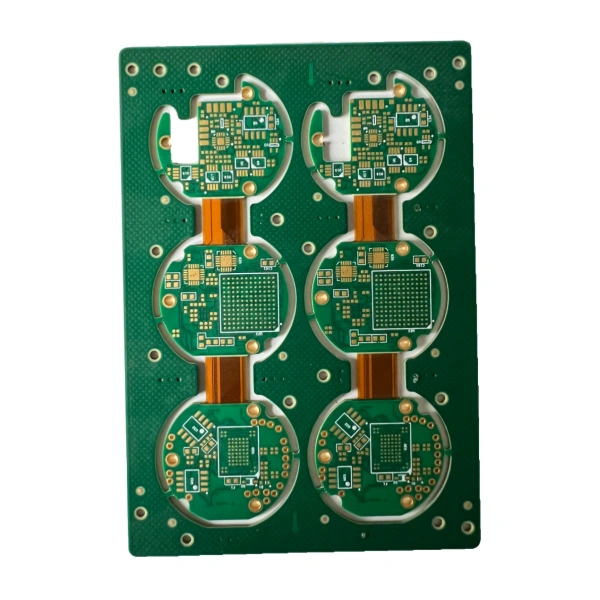

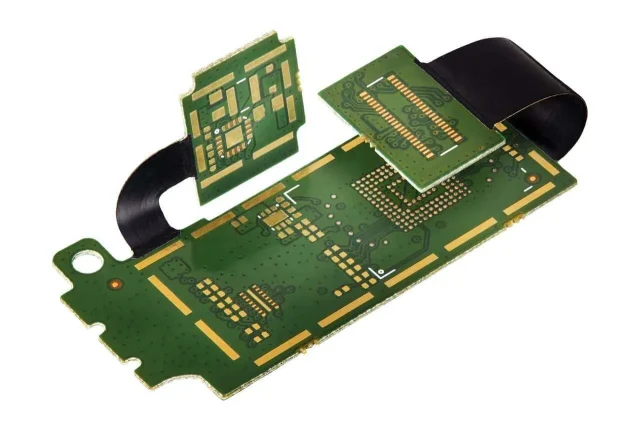

A multilayer rigid-flex PCB integrates rigid PCB sections and flexible circuit sections into a single board structure. Multiple copper layers are interconnected through plated vias and flexible interconnects, eliminating the need for connectors and cables.

This structure improves electrical reliability and allows complex 3D packaging designs.

Key Capabilities of a Multilayer Rigid-Flex PCB Manufacturer

A qualified multilayer rigid-flex PCB manufacturer offers:

-

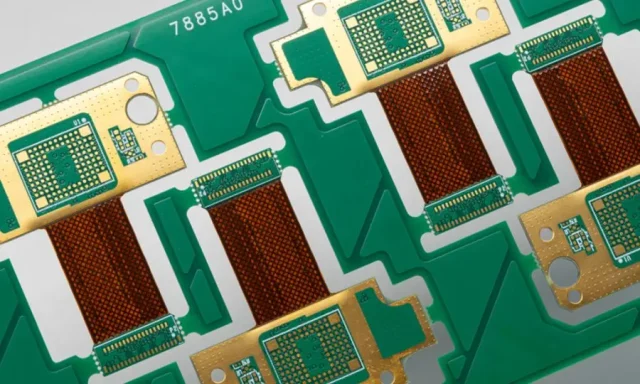

Complex multilayer stackup design

-

Rigid and flex material lamination control

-

High-precision drilling and via plating

-

Controlled impedance and high-speed routing

-

Advanced inspection and reliability testing

These capabilities ensure consistent quality and performance.

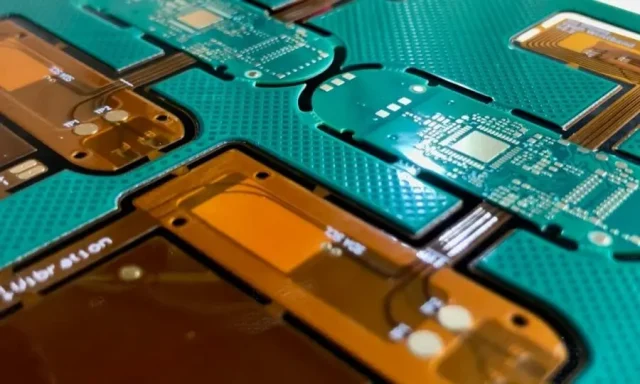

Manufacturing Challenges in Multilayer Rigid-Flex PCBs

Producing multilayer rigid-flex PCBs involves unique challenges, including:

Material Compatibility

Rigid and flexible materials require precise lamination processes to ensure long-term reliability.

Layer Alignment Accuracy

Multilayer rigid-flex PCBs demand tight registration tolerances across all layers.

Thermal and Mechanical Stress Control

Manufacturers must manage thermal expansion and mechanical stress to prevent delamination and cracking.

An experienced multilayer rigid-flex PCB manufacturer is essential to overcome these challenges.

Reliability and Quality Control

A professional multilayer rigid-flex PCB manufacturer implements strict quality control, including:

-

AOI and X-ray inspection

-

Electrical testing

-

Flex bending and stress testing

-

Thermal cycling and reliability validation

These processes ensure stable performance in demanding environments.

Applications of Multilayer Rigid-Flex PCBs

Multilayer rigid-flex PCBs are widely used in:

-

Medical devices

-

Aerospace and defense electronics

-

Automotive electronics

-

Wearable and portable devices

-

Industrial and high-reliability systems

These applications demand durability, compact design, and long-term reliability.

Advantages of Choosing a Multilayer Rigid-Flex PCB Manufacturer

Working with a dedicated multilayer rigid-flex PCB manufacturer provides:

-

Reduced assembly complexity

-

Improved signal integrity

-

Enhanced mechanical reliability

-

Optimized space utilization

This makes rigid-flex PCBs ideal for advanced electronic systems.

How to Select the Right Multilayer Rigid-Flex PCB Manufacturer

When choosing a multilayer rigid-flex PCB manufacturer, consider:

-

Proven experience with complex rigid-flex designs

-

Advanced manufacturing equipment

-

Quality and reliability certification

-

Engineering and DFM support

-

Capability to scale from prototype to mass production

The right partner ensures project success.

Conclusion

A professional multilayer rigid-flex PCB manufacturer plays a critical role in delivering compact, reliable, and high-performance electronic solutions. With advanced manufacturing processes and strict quality control, multilayer rigid-flex PCBs support the next generation of complex electronic systems.

Partnering with an experienced manufacturer ensures your multilayer rigid-flex PCB projects meet the highest technical and reliability standards.