As RF, microwave, and high-speed communication technologies continue to advance, partnering with a qualified high frequency PCB OEM has become essential for companies seeking stable performance, consistent quality, and scalable production. High frequency PCBs require far more than standard fabrication—they demand specialized materials, precise impedance control, and strict manufacturing discipline.

This article explains what a high frequency PCB OEM is, what capabilities matter most, and how OEM manufacturing supports RF and microwave product success.

What Is a High Frequency PCB OEM?

A high frequency PCB OEM is a manufacturing partner that provides original equipment manufacturing services specifically for high-frequency, RF, and microwave PCB designs. OEM services typically cover:

-

High frequency PCB fabrication

-

Material selection and stack-up optimization

-

OEM branding and customized production

-

Quality control and testing

-

Support from prototyping to mass production

Unlike standard PCB suppliers, high frequency PCB OEMs focus on performance-critical applications where signal integrity is essential.

Key Capabilities of a High Frequency PCB OEM

1. Expertise in High Frequency Materials

A reliable high frequency PCB OEM must be experienced with advanced RF materials, including:

-

Rogers laminates for low loss and stable dielectric properties

-

PTFE-based materials for microwave and millimeter-wave frequencies

-

Hybrid stackups combining RF materials with FR-4 for cost-effective OEM solutions

Material expertise ensures predictable electrical performance across different production volumes.

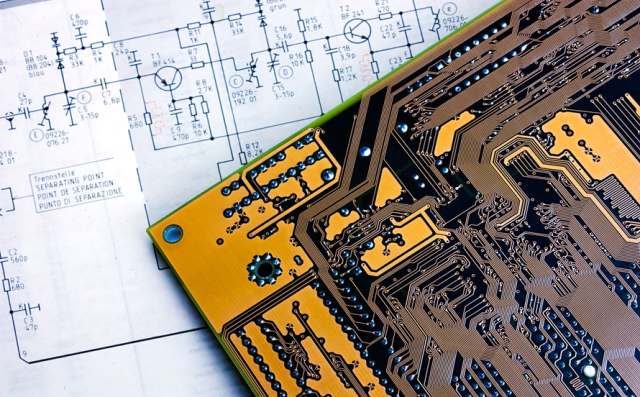

2. Precise Impedance Control

Accurate impedance control is critical in high frequency PCB OEM manufacturing.

-

Controlled impedance structures reduce signal reflection

-

Tight tolerance control (±5% or better) ensures consistency

-

TDR testing verifies real impedance performance

OEM partners with strong impedance control capabilities help ensure RF designs meet specification requirements.

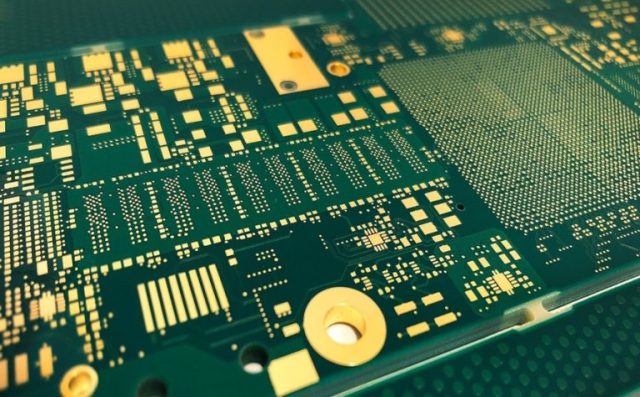

3. Advanced Manufacturing and Process Control

High frequency PCB OEM production requires advanced fabrication processes, such as:

-

Precision lamination and etching

-

Fine line width and spacing control

-

Controlled copper plating and surface finishes

-

Stable multilayer stack-up processes

These capabilities enable OEM manufacturers to deliver repeatable, high-quality results.

Quality Assurance and Testing in OEM Manufacturing

Professional high frequency PCB OEMs implement strict quality assurance systems, including:

-

TDR impedance testing

-

Electrical testing and RF performance validation

-

AOI and X-ray inspection

-

Reliability and consistency checks across batches

Comprehensive testing ensures every OEM PCB meets electrical and mechanical specifications.

Applications of High Frequency PCB OEM Services

High frequency PCB OEM solutions are widely used in:

-

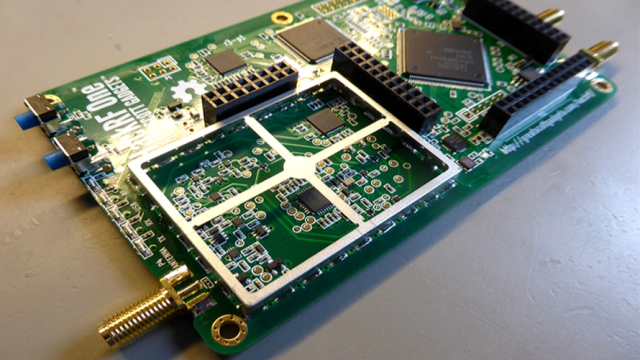

RF front-end modules

-

5G and wireless communication systems

-

Radar and satellite electronics

-

Automotive radar and ADAS

-

Aerospace and defense applications

In these industries, stable RF performance and long-term reliability are mandatory.

Conclusion

Choosing the right high frequency PCB OEM partner is critical for delivering reliable RF and microwave products. From advanced materials and impedance control to scalable OEM manufacturing and strict quality assurance, a qualified OEM ensures performance consistency from prototype to mass production.

By working with an experienced high frequency PCB OEM manufacturer, companies can reduce development risk, improve signal integrity, and achieve long-term manufacturing success.