Why Small Batch PCB Matters in Modern Electronics Development

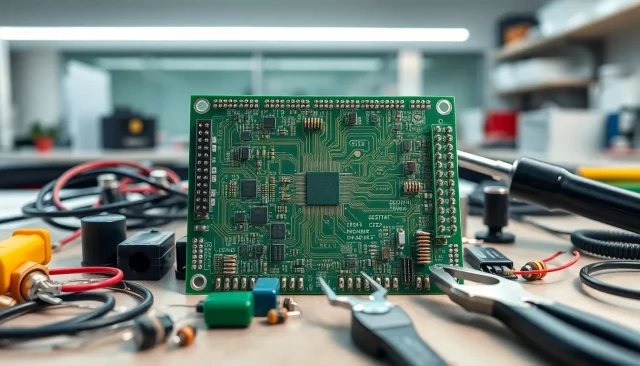

In today’s electronics industry, product lifecycles are shorter and design iterations are more frequent. Before committing to mass production, engineering teams must validate signal integrity, power stability, thermal behavior, and manufacturability. Small batch PCB manufacturing plays a critical role in this phase by enabling controlled, low-risk production runs without sacrificing process quality.

At KKPCB, small batch PCB services are designed to bridge the gap between prototype validation and volume manufacturing, allowing engineers to test real production processes on a manageable scale.

What Is Small Batch PCB Manufacturing?

Small batch PCB typically refers to low-quantity PCB fabrication and assembly, ranging from a few pieces to several hundred units. Unlike quick-turn prototypes that focus only on speed, small batch PCB manufacturing emphasizes:

-

Production-grade materials and processes

-

Stable stackup and impedance control

-

Assembly repeatability

-

Real-world functional validation

This approach ensures that performance data collected during testing remains relevant when scaling to mass production.

Engineering Advantages of Small Batch PCB Production

Design Validation Under Real Manufacturing Conditions

Small batch PCB fabrication uses the same lamination, drilling, plating, and etching processes as volume production. This allows engineers to verify:

-

Controlled impedance accuracy

-

Via reliability and aspect ratio limits

-

Copper distribution and thermal balance

Such validation is critical for high-speed PCB, RF PCB, and HDI PCB designs, where minor process deviations can significantly impact performance.

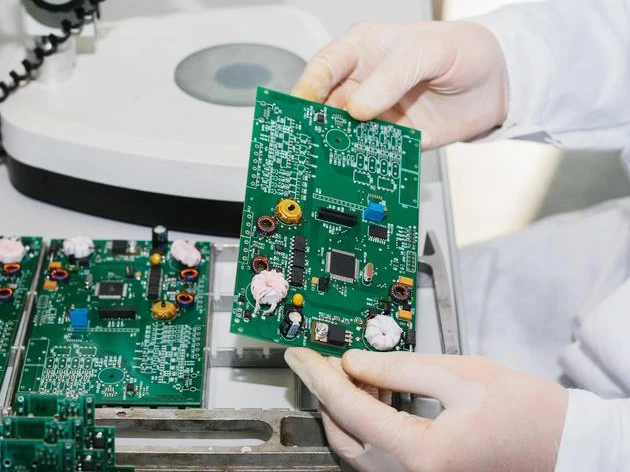

Early Detection of Assembly and Reliability Risks

When combined with small batch PCBA, potential assembly issues can be identified early, including:

-

Solder joint integrity for fine-pitch components

-

BGA and QFN reliability

-

Reflow profile compatibility with PCB materials

-

Thermal stress behavior during operation

Small batch PCB assembly provides data-driven insight before full-scale production investment.

Small Batch PCB Capabilities at KKPCB

PCB Fabrication Scope

KKPCB supports small batch PCB manufacturing across a wide range of technologies:

-

Rigid, flex, and rigid-flex PCBs

Each small batch PCB project undergoes DFM and stackup review to ensure consistency with future mass production.

Material and Process Consistency

For small batch PCB orders, KKPCB applies:

-

Production-grade laminate materials

-

Tight dielectric thickness control

-

Stable copper plating and etching tolerances

-

Consistent impedance testing where required

This ensures that small batch results accurately reflect large-scale manufacturing outcomes.

Small Batch PCB vs. Prototype PCB

While prototype PCBs focus primarily on speed and functional proof, small batch PCBs emphasize repeatability and process stability. Small batch manufacturing is ideal when:

-

Designs are close to release

-

Electrical performance must be statistically verified

-

Assembly yield needs evaluation

-

Regulatory or customer qualification is required

In many NPI projects, small batch PCB production is the final step before volume ramp-up.

Typical Applications for Small Batch PCB Manufacturing

Small batch PCB services are commonly used in:

-

New product introduction (NPI) programs

-

High-speed computing and networking equipment

-

RF transceivers and wireless communication modules

-

Industrial automation and control systems

-

Medical, automotive, and aerospace electronics

In these applications, controlled low-volume production reduces technical risk while preserving engineering accuracy.

Quality Control and Testing

KKPCB integrates quality assurance into every small batch PCB project, including:

-

Electrical testing and impedance verification

-

Visual inspection and AOI

-

Assembly inspection and X-ray analysis (when required)

-

Process traceability for materials and components

This ensures that small batch PCB products meet both engineering and reliability expectations.

Conclusion

Small batch PCB manufacturing is a strategic step in modern electronics development. It allows engineering teams to validate design assumptions, manufacturing processes, and assembly reliability without the cost and risk of full-scale production.

With flexible quantities, production-grade processes, and engineering-focused support, KKPCB’s small batch PCB solutions help customers transition smoothly from prototype validation to stable mass production.