What Is PCB Turnkey?

PCB Turnkey refers to a one-stop PCB solution where a single manufacturer manages the entire process—from bare PCB fabrication and electronic component procurement to assembly, testing, and logistics. Instead of coordinating multiple suppliers, customers work with one partner who takes full responsibility for quality, schedule, and delivery.

At KKPCB, PCB Turnkey is engineered as a process-driven manufacturing model, designed to reduce communication gaps, eliminate sourcing risks, and ensure electrical and mechanical consistency across the full product lifecycle.

Why PCB Turnkey Matters in Modern Electronics Manufacturing

As electronic systems become more complex and time-to-market pressure increases, fragmented sourcing introduces risk. PCB Turnkey manufacturing addresses these challenges by integrating all stages under one controlled workflow.

Key drivers behind PCB Turnkey adoption include:

-

Shortened product development cycles

-

Reduced supply chain uncertainty

-

Improved yield and reliability

-

Lower total project management cost

For high-speed digital, RF, industrial control, and automotive electronics, PCB Turnkey services provide predictability that traditional multi-vendor models cannot match.

Core Components of a PCB Turnkey Service

PCB Fabrication

The foundation of any PCB Turnkey solution is precision PCB manufacturing. Controlled impedance, stackup integrity, material traceability, and lamination quality are tightly managed to ensure the board meets design intent.

Component Sourcing

PCB Turnkey includes BOM management and component procurement through verified supply channels. This minimizes risks related to:

-

Counterfeit components

-

Obsolete or long-lead-time parts

-

Inconsistent component specifications

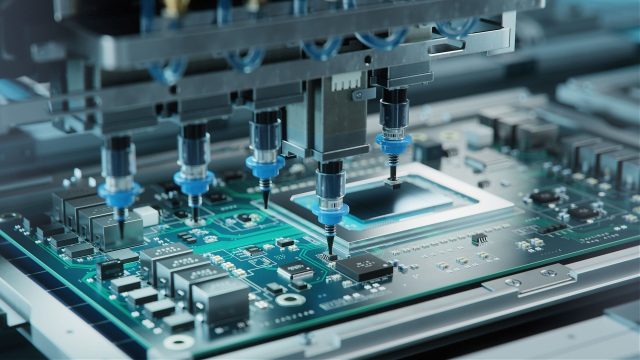

PCB Assembly (SMT & THT)

Turnkey PCB assembly integrates automated SMT lines, through-hole insertion, and selective soldering, ensuring:

-

High placement accuracy

-

Stable solder joint quality

-

Repeatable production yields

Testing and Inspection

A professional PCB Turnkey service incorporates inspection and testing such as:

-

AOI (Automated Optical Inspection)

-

X-ray inspection for BGA/QFN

-

Functional and electrical testing

This ensures defects are identified early, reducing downstream failure risks.

Logistics and Delivery

Final packaging, labeling, and shipment are included, enabling customers to receive ready-to-use PCBAs without additional coordination.

Advantages of PCB Turnkey Services

Single Point of Responsibility

With PCB Turnkey, accountability is clear. Design issues, material mismatches, or assembly challenges are resolved internally—saving time and avoiding cross-vendor disputes.

Faster Time-to-Market

Parallel processing of fabrication, sourcing, and assembly significantly reduces lead time, especially for prototypes and low-to-mid volume production.

Improved Quality Consistency

Unified process control ensures that PCB design assumptions align with fabrication tolerances and assembly constraints.

Cost Optimization

Although unit pricing may appear higher, PCB Turnkey reduces hidden costs related to rework, delays, inventory management, and engineering coordination.

PCB Turnkey vs Consignment Model

| Aspect | PCB Turnkey | Consignment PCB |

|---|---|---|

| Component sourcing | Manufacturer-managed | Customer-managed |

| Supply chain risk | Low | Higher |

| Lead time | Shorter | Longer |

| Quality accountability | Single owner | Split responsibility |

| Project coordination | Simple | Complex |

For mission-critical or high-complexity electronics, PCB Turnkey offers a more robust and scalable manufacturing approach.

Applications Best Suited for PCB Turnkey

PCB Turnkey solutions are widely used in:

-

Industrial automation and control systems

-

Medical electronics and diagnostic equipment

-

Automotive electronics and EV modules

-

High-speed digital and RF communication systems

-

IoT devices and embedded systems

These applications benefit from the reliability, traceability, and efficiency of turnkey PCB manufacturing.

Why Choose KKPCB for PCB Turnkey Services

KKPCB delivers PCB Turnkey services with an engineering-first mindset, integrating:

-

Advanced PCB fabrication capabilities

-

Professional BOM and component sourcing

-

High-precision SMT assembly

-

Strict quality and process control

By aligning design intent with manufacturing execution, KKPCB ensures that PCB Turnkey projects transition smoothly from prototype to mass production.

Conclusion

PCB Turnkey services are no longer just a convenience—they are a strategic manufacturing solution for modern electronics. By consolidating fabrication, sourcing, assembly, and testing into a single workflow, PCB Turnkey manufacturing reduces risk, improves quality, and accelerates innovation.

With KKPCB as your PCB Turnkey partner, you gain a reliable, scalable, and technically driven solution that supports your product from concept to delivery.