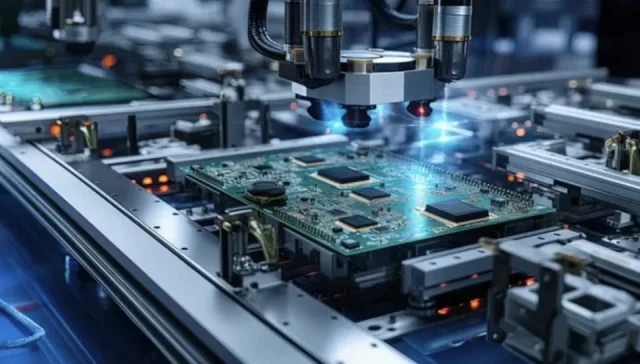

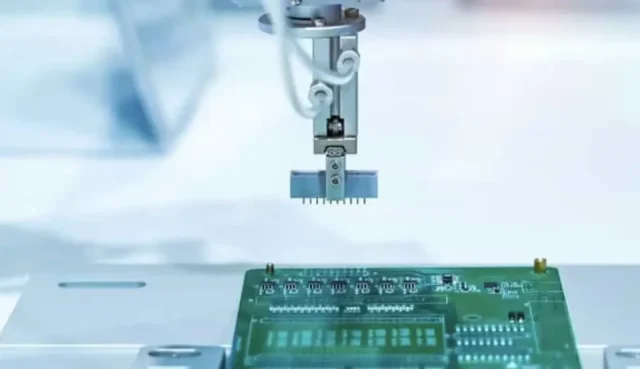

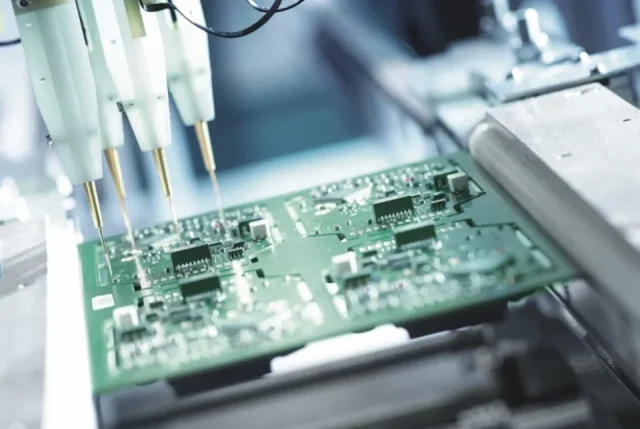

Industrial Automation PCB: High-Reliability Engineering for Modern Automated Systems

Industrial Automation PCB technology is the backbone of automated factories, motion-control systems, industrial robots, PLC modules, sensor interfaces, and high-duty power conversion equipment. Unlike consumer electronics, an Industrial Automation PCB must deliver continuous uptime, deterministic performance, and long operational life under electrical noise, mechanical stress, and thermal cycling. Engineering such a PCB requires a multidimensional approach that blends material science, EMI control, rugged power design, and system-level reliability.

1. Reliability as the First Principle in Industrial Automation PCB Design

Industrial environments are electrically hostile. High-voltage motors, VFDs, RF noise, and inductive loads create a spectrum of disturbances. An Industrial Automation PCB must maintain signal integrity and power stability even as the surrounding environment fluctuates wildly.

Key reliability factors include:

• Wide operating-temperature laminates for 24/7 duty cycles

• High creepage and clearance distances for industrial voltages

• Conformal coating for dust, chemical vapors, and humidity

• Reinforced FR-4 or high-CTE-resistance substrates

Reliability is not a feature—it is a baseline expectation in Industrial Automation PCB engineering.

2. Signal Integrity and Real-Time Determinism

Automation networks and control loops demand precise timing. Any delay, jitter, or distortion can cascade into system-wide failures.

Typical Industrial Automation PCB signal paths include:

• Industrial Ethernet (Profinet, EtherCAT, Modbus TCP)

• High-speed SPI/I²C for sensor modules

• Encoder signals for servo control

• Differential pairs for deterministic fieldbus

To preserve timing accuracy, designers optimize:

• Controlled-impedance traces

• Harmonic decoupling networks

• Ground-referenced routing for low jitter

• Segmented noise zones between logic and power domains

A high-performance Industrial Automation PCB effectively becomes the nervous system of the factory floor.

3. Power Integrity for Motors, Actuators, and Converters

Automation hardware often sits next to heavy loads—motors, solenoids, heaters, pneumatic controllers. Power surges are routine.

A well-engineered Industrial Automation PCB uses:

• Multi-stage LC filtering for stable DC rails

• TVS and surge suppression for inductive kickback

• Heavy copper (2–4 oz) for actuator drivers

• Proper MOSFET heat spreading and via-in-pad cooling

• Segregated power/ground planes for clean regulation

Power integrity directly determines whether the system can operate uninterrupted for years.

4. EMI/EMC Engineering for Harsh Manufacturing Floors

Industrial systems undergo strict EMI/EMC compliance (EN 61000-6-2/4). An Industrial Automation PCB must withstand both radiated and conducted interference.

Key techniques include:

• Shielded differential routing for data lines

• Ferrite-segmented power entry

• Isolated DC/DC modules for noise-prone zones

• Ground stitching fences to contain high-frequency currents

• Layer stacks designed for EMI containment rather than just routing convenience

A disciplined EMI design ensures stable communication and eliminates unexpected field failures.

5. Thermal Engineering for Continuous Duty Cycles

High-efficiency automation does not forgive thermal mistakes. Components operate at full load for years.

Industrial Automation PCB thermal strategies include:

• Heavy copper to reduce IR losses

• Metal-based cores for high-power modules

• Thermal vias under regulators and MOSFETs

• Heat-spreading copper islands to avoid hot spots

Thermal stability directly impacts long-term MTBF (mean time between failures).

6. Long Lifecycle and Component Supply Stability

Factories expect automation systems to run 10–15 years. Industrial Automation PCB design accounts for:

• Component selection with guaranteed long-term availability

• Hardware abstraction layers to allow controlled redesigns

• Modular PCBs that can be replaced without full system revalidation

Industrial Automation PCB reliability extends beyond manufacturing—it is a lifecycle philosophy.

Conclusion

An Industrial Automation PCB is far more than a conductive platform; it is a precision-engineered system designed for ruggedness, real-time determinism, and decades of reliable performance. As factories evolve toward Industry 4.0 and intelligent automation, the engineering standards for Industrial Automation PCB manufacturing continue to rise. The future belongs to PCBs that are smarter, tougher, more thermally stable, and designed for coexistence with high-power, high-noise industrial environments.

High-quality Industrial Automation PCB design becomes the foundation that enables robots to move accurately, sensors to report truthfully, and machines to operate together as a coherent intelligent ecosystem.