In next-generation intelligent aerial surveillance platforms, UAV manufacturers face increasing demands for real-time data fusion, long-range imaging, high-throughput RF links, and multi-sensor synchronization. These requirements place enormous pressure on the UAV PCB architecture, especially in compact airframes where thermal, mechanical, and electromagnetic constraints are all tightly coupled. This is why high-density PCB design (HDI PCB), RF PCB optimization, and high-frequency PCB materials have become core enablers of modern UAV surveillance electronics.

High-Density UAV PCB as the Core of Multi-Sensor Processing

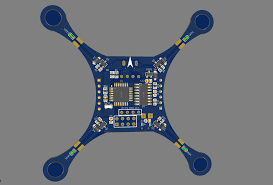

A high-density UAV PCB integrates multiple subsystems—IMU, GPS, AI processors, radar modules, camera interfaces, RF transceivers—into a compact embedded system. This high level of electronic integration significantly improves multi-sensor processing efficiency by reducing interconnect lengths, lowering insertion loss, and enabling higher signal integrity.

Key advantages of high-density PCB design in UAV platforms:

1. Higher Multi-Sensor Bandwidth & Faster Data Fusion

High-density routing and microvia technology reduce signal paths between camera sensors, LiDAR, radar, RF modules, and the onboard AI computing unit.

-

Shorter trace lengths → improved high-frequency performance

-

Lower EMI → cleaner data streams

-

Improved synchronization → higher multi-sensor fusion accuracy

This directly enhances real-time target tracking, object recognition, and geospatial analysis in surveillance UAVs.

RF PCB Optimization for High-Frequency UAV Communications

Long-range UAV communication depends heavily on RF PCB design, millimeter-wave routing, and stable dielectric materials. For surveillance drones that rely on 5.8 GHz, 24 GHz, or 77 GHz radar bands, signal integrity becomes mission-critical.

RF PCB requirements for UAV surveillance systems:

-

Low-loss materials (Rogers RO4350B, RO4003C, PTFE)

-

Controlled impedance microstrip & stripline routing

-

Isolation zones for RF, AI processing, and power systems

-

Low-noise power distribution for RF front ends

Optimized RF PCB layouts reduce phase noise, improve antenna efficiency, and ensure reliable long-distance data transmission—even in electromagnetically noisy environments.

Thermal Management in Compact UAV PCB Systems

High-density UAV PCB designs pack processors, FPGA modules, power converters, and RF amplifiers into tight volumes. Without proper thermal strategies, multi-sensor performance deteriorates rapidly.

Thermal strategies include:

-

Heavy copper layers for heat spreading

-

Via-in-pad microvias for direct thermal pathways

-

Embedded metal cores or heat-sink layers

-

Optimal component placement for airflow

Reliable thermal engineering ensures continuous operation of UAV AI processors and RF subsystems during high-altitude, long-endurance missions.

Mechanical Reliability for High-Vibration UAV Environments

Intelligent UAV surveillance platforms operate under intense vibration and shock loads during takeoff, landing, and maneuvers.

High-density PCBs significantly improve mechanical reliability through:

-

Rigid-flex PCB integration for sensor interconnects

-

Stacked microvias with copper filling

-

Edge plating for structural reinforcement

-

Lower connector count → fewer failure points

This enhances long-term durability, especially in harsh-environment UAV missions.

Power Integrity for Multi-Sensor & AI Workloads

With multiple sensors, RF modules, and embedded GPUs/NPUs running simultaneously, UAVs require robust power integrity (PI).

High-density UAV PCBs provide:

-

Short power distribution paths

-

Lower IR drop

-

Reduced noise coupling into RF and sensor circuits

-

Stable voltage for real-time AI analytics

Stable power integrity ensures smooth operation of camera arrays, radar transceivers, GNSS modules, and AI processors.

Why High-Density UAV PCB Designs Are Essential for Intelligent Surveillance

Combining HDI PCB, RF PCB, rigid-flex structures, and low-loss materials enables UAV platforms to achieve:

-

Faster multi-sensor data fusion

-

Higher RF communication stability

-

Lower latency embedded processing

-

Greater mission endurance & reliability

-

Smaller and lighter surveillance payloads

This is why high-density UAV PCB architecture is now considered the foundation of next-generation military, security, mapping, border-control, and disaster-monitoring UAV systems.